- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

250 Sandmaster Pump-6X5X11- Short Frame Pump

OEM reference Nos: MISSION SANDMASTER/MCM 250 Short Frame

Our Part Nos: 250 SD

Application: Solid Control, Cementing

Origin: China

Lead time: Stock-1 week

Certificate: ISO 9001

GMS proudly delivers high-performance 250 Sandmaster Pump solutions engineered to meet or exceed OEM standards. Trusted by oil and gas operators, drilling contractors, and EPC companies, our pumps ensure reliability in the most demanding environments.

250 Sandmaster Pump Introduction

Compact. Powerful. Exceptionally Versatile.

The 250 Sandmaster Pump-6X5X11- Short Frame Pump is engineered for performance in tight spaces without compromising power. Designed with all the key features of the Magnum I, this compact solution stands out for its ability to seamlessly integrate with hydraulic motor drives—making it a top choice for oilfield fracturing units, water well mixing systems, and pump charging operations.

What sets the Sandmaster apart? A shorter frame and shaft—trimmed by 4 inches—significantly reduce the pump’s overall length, giving you greater flexibility where space is at a premium and prime mover options are limited. And with full compatibility of internal components with the Magnum, it delivers both reliability and cost efficiency.

When space is tight, choose Sandmaster—engineered for performance where it matters most.

Product Advantages

Stable Performance

The product is designed to deliver stable and reliable performance in even the toughest conditions.

Industry Standards

Our product is fully compliant with international standards, including ISO certifications, ensuring that it meets the highest safety and quality benchmarks.

Product Info

|

Product Name |

250 Sandmaster Pump-6X5X11- Short Frame Pump |

|

OEM Reference Nos |

MISSION Magnum/MCM 250 |

|

GMS Part Nos |

GMS-250-6511 |

|

Application |

Cement Charge Pump Blender Waterwell Drilling Other Mobile uses |

|

Origin |

China |

|

Lead Time |

Stock-1 week |

|

Certificate |

ISO 9001 |

Product Application

The 250 Sandmaster Pump-6X5X11- Short Frame Pump is primarily applied in solid control tasks and cementing activities.

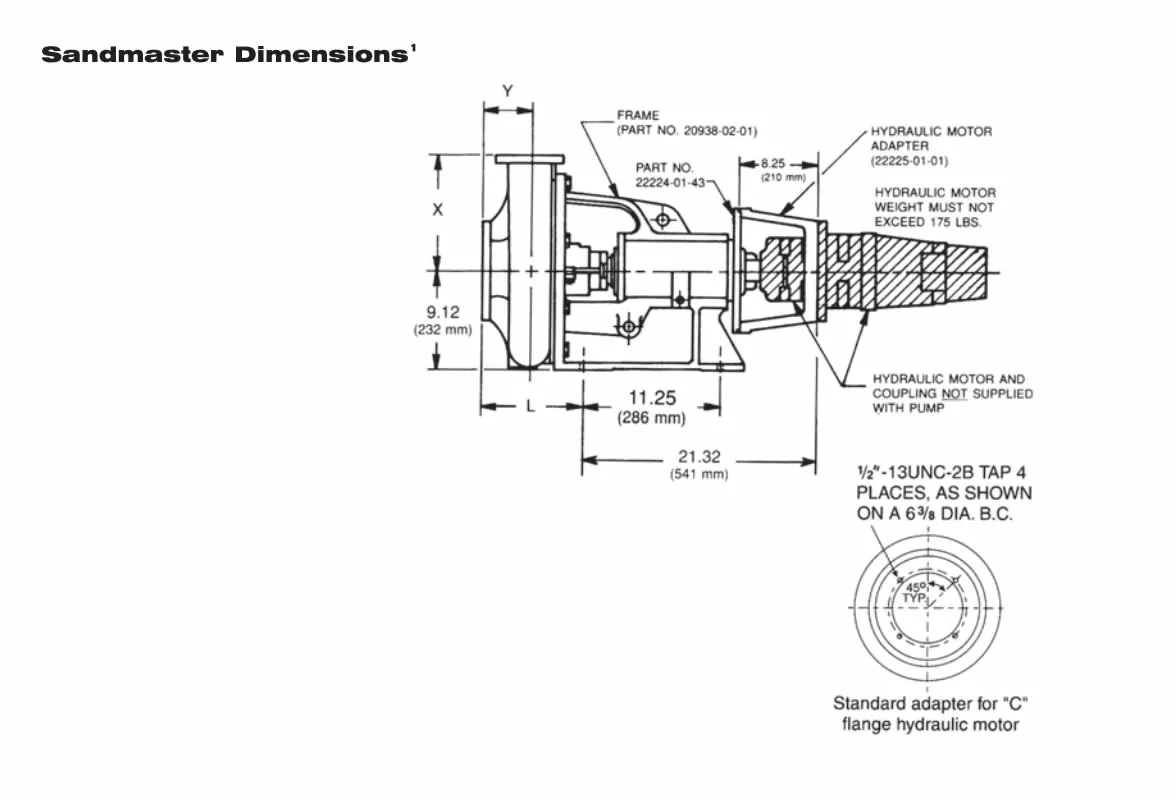

Products drawing

Product parts list

|

ITEM |

QTY |

MISSION PART No. |

DESCRIPTION |

MATERAIL |

WEIGHT kg |

|||||||||

|

1* |

1 |

See below |

Casing |

|

|

|||||||||

|

1A |

1 |

10399-46-1 |

Gasket,casing |

Vellumoid |

0.01 |

|||||||||

|

1B |

12 |

3932-61 |

Nut,casing |

Stl |

0.05 |

|||||||||

|

1C |

12 |

3862-76 |

Stud,casing |

Stl |

0.16 |

|||||||||

|

1D |

1 |

8505-04-01 |

Plug,Casing Drain |

Stl |

0.03 |

|||||||||

|

1E |

1 |

8505-04-01 |

Plug,flush line |

Stl |

0.03 |

|||||||||

|

2* |

1 |

See below |

Impeller |

|

|

|||||||||

|

2A |

1 |

19110-72 |

Seal,impeller |

Viton |

0.002 |

|||||||||

|

2B |

1 |

7300239 |

Washer,impeller |

Stl |

0.02 |

|||||||||

|

2C |

1 |

7415648 |

Bolt,impeler lock |

Stl |

0.15 |

|||||||||

|

3*# |

1 |

22223-01-30 |

Stuffing box,mech.seal |

Hard Iron |

20 |

|||||||||

|

3*& |

1 |

20614-01-30 |

Stuffing box,packed |

Hard Iron |

20 |

|||||||||

|

3A |

2 |

3861-117 |

Bolt,stuffing box |

Stl |

0.05 |

|||||||||

|

4 |

1 |

20622A |

Gland assy,packing |

Stl 304 |

1 |

|||||||||

|

5A# |

1 |

22451-1 |

Seal,mechanical |

Tung/Tung |

1 |

|||||||||

|

5A# |

1 |

648402600 |

Packing, Shaft - M.S. Backup |

Graphite Acrylic |

0.3 |

|||||||||

|

5A# |

Option |

648402600 |

Packing, Shaft - M.S. Backup |

Kevlar |

0.3 |

|||||||||

|

5A |

1 |

25014-04M-B |

Packing, Shaft - w/latern ring |

Graphite/Acrylic |

0.5 |

|||||||||

|

5A |

Option |

250147-04M-D |

Packing, Shaft - w/latern ring |

Teflon, White |

0.5 |

|||||||||

|

5A# |

Option |

25014-04M-C |

Packing, Shaft - w/latern ring |

Kevlar |

0.5 |

|||||||||

|

6 |

2 |

B3701A |

Bolt assy,gland |

Stl 304 |

0.15 |

|||||||||

|

7 |

1 |

20939-02-33 |

Shaft |

42CrMo |

15 |

|||||||||

|

7A |

1 |

20943-04A |

Sleeve,shaft |

38CrMoAl |

1 |

|||||||||

|

7B |

1 |

4371-5-21 |

Key,shaft |

Stl |

0.11 |

|||||||||

|

7C |

1 |

23444-01-72 |

Seal,shaft sleeve |

Viton |

0.005 |

|||||||||

|

8 |

1 |

22210-1A |

Deflector assembly |

Composite |

0.4 |

|||||||||

|

9 |

1 |

20938-02-1 |

Frame,grease lubricated |

Cast iron |

75 |

|||||||||

|

9C |

1 |

8505-04-01 |

Plug, Frame Drain |

Stl |

0.033 |

|||||||||

|

9D |

1 |

8267-01 |

Breather |

Stl |

0.1 |

|||||||||

|

9G |

3 |

2538-1H |

Bolt,casing jack |

Stl |

0.16 |

|||||||||

|

10A |

1 |

20626 |

Cover,inboard bearing |

Iron |

2.6 |

|||||||||

|

10B |

1 |

20625 |

Gasket,I.B.Brg.Cover |

Vegetable fiber |

0.01 |

|||||||||

|

10C |

1 |

20619-01 |

Oil seal, I.B.Brg.Cover |

Buna-n |

0.06 |

|||||||||

|

10D |

2 |

3861-1 |

Bolt, I.B.Brg.Cover |

Stl |

0.03 |

|||||||||

|

10E |

2 |

3932-2 |

Nut, I.B.Brg.Cover |

Stl |

0.07 |

|||||||||

|

10F |

1 |

20620-01 |

Exclusion Seal, I.B. Brg. Cvr. |

Buna-n |

0.01 |

|||||||||

|

10G |

1 |

21641-01 |

Grease fitting |

Stl |

0.07 |

|||||||||

|

10H |

1 |

648411908 |

Grease fitting |

Stl |

0.07 |

|||||||||

|

11 |

1 |

661 00901 OA |

Bearing, Inboard & Spacer |

Roller |

2.1 |

|||||||||

|

11 |

1 |

20615-1 |

Bearing,inboard |

Vendor |

2.1 |

|||||||||

|

12 |

1 |

20624-01-01 |

Housing,O.B.bearing |

Iron |

6 |

|||||||||

|

12A |

1 |

7496-253 |

Seal, O.B.Brg.housing |

Buna-n |

0.01 |

|||||||||

|

12B |

4 |

3861-138 |

Bolts, O.B.Brg.housing |

Stl |

0.05 |

|||||||||

|

12C |

2 |

3932-62 |

Nut, O.B.Brg.housing jam |

Stl |

0.016 |

|||||||||

|

13 |

1 |

20617A |

Cover,O.B.Bearing |

Iron |

1.8 |

|||||||||

|

13A |

1 |

19368-01 |

Grease zerk, O.B.Brg.Cover |

Brass |

0.01 |

|||||||||

|

13B |

1 |

7496-26 |

O-ring, O.B.Brg.Cover |

Buna-n |

0.001 |

|||||||||

|

13C |

1 |

20619-02 |

Oil seal, O.B.Brg.Cover |

Buna-n |

0.04 |

|||||||||

|

13D |

2 |

3861-139 |

Bolt, O.B.Brg.Cover |

Stl |

0.025 |

|||||||||

|

14 |

2 |

20616-1 |

Bearing, O.B. |

Vendor |

1.5 |

|||||||||

|

14A |

1 |

6124-4 |

Lockwasher,O.B.Bearing |

Stl |

0.01 |

|||||||||

|

14B |

1 |

6123-4 |

Locknut, O.B.Bearing |

Stl |

0.22 |

|||||||||

|

Casings-includes studs,nuts & gasket |

||||||||||||||

|

1* |

1 |

19203-01-30A |

Casing,3×2×13 |

Hard Iron |

55 |

|||||||||

|

1* |

1 |

19205-01-30A |

Casing,4×3×13 |

Hard Iron |

57 |

|||||||||

|

1* |

1 |

19222-01-30A |

Casing, 5×4×14 |

Hard Iron |

88 |

|||||||||

|

1* |

1 |

19122-01-30A |

Casing,6×5×11 |

Hard Iron |

90 |

|||||||||

|

1* |

1 |

19123-01-30A |

Casing, 6×5×14 |

Hard Iron |

95 |

|||||||||

|

1* |

1 |

19763-01-30A |

Casing, 8×6×11 |

Hard Iron |

97 |

|||||||||

|

1* |

1 |

19117-01-30A |

Casing,8×6×14 |

Hard Iron |

125 |

|||||||||

|

1* |

1 |

20937-01-30A |

Casing,10×8×14 |

Hard Iron |

155 |

|||||||||

|

Impellers |

||||||||||||||

|

|

2* |

1 |

19204-XX-30 |

Impeller,3×2×13 |

Hard Iron |

9 |

||||||||

|

|

2* |

1 |

19206-XX-30 |

Impeller,4×3×13 |

Hard Iron |

12.5 |

||||||||

|

|

2* |

1 |

19224-XX-30 |

Impeller,5×4×14 |

Hard Iron |

16 |

||||||||

|

|

2* |

1 |

19121-XX-30 |

Impeller,6×5×11 |

Hard Iron |

14 |

||||||||

|

|

2* |

1 |

19121-XX-30 |

Impeller, 6×5×14 |

Hard Iron |

18 |

||||||||

|

|

2* |

1 |

19116-XX-30 |

Impeller, 8×6×11 |

Hard Iron |

18 |

||||||||

|

|

2* |

1 |

19116-A0-30 |

Impeller,8×6×14 |

Hard Iron |

20 |

||||||||

|

|

2* |

1 |

21867-XX-30 |

Impeller,10×8×14 |

Hard Iron |

20 |

||||||||

Why Choose GMS as Your Supplier?

Choosing GMS means opting for reliability and expertise. Our credentials include:

- ISO 9001 Certificate: Our ISO 9001 certification illustrates our immovable commitment to conveying top-quality items and administrations through a steady and viable quality administration system.

- Long time Industry Involvement: With over ten a long time of industry encounter, we bring a riches of information and mastery, guaranteeing dependable, high-quality items that surpass client expectations.

- Fast Reaction: We esteem your time, prioritizing fast reactions to request, guaranteeing you get quick, clear communication and opportune arrangements to keep your ventures on track.

- Large Stock: Our broad stock of items guarantees a wide determination, prepared to meet your prompt needs and give you with fast, proficient arrangements for any project.

- Short Lead Time: We pride ourselves on advertising brief lead times, streamlining our generation and conveyance forms to offer assistance you meet venture due dates and dodge pointless delays.

- Good After-Sales Administrations: Our committed after-sales bolster guarantees that any concerns are quickly tended to, giving you with persistent help for a hassle-free post-purchase experience.

- Flexible Arrangements: We offer adaptable arrangements custom-made to your particular needs, giving customized items and administrations that guarantee the idealize fit for your interesting necessities.

We understand the demands of the oil and gas industry and are committed to providing tailored solutions that meet your unique needs.

FAQ

Q: What is the lead time for the product?

A: The lead time depends on required quantities; we usually have stock available for small quantities.

Q: Do you have any certificates for the product?

A: Yes, we possess an ISO certificate for Centrifugal Pumps and parts

Q: How can I place an order?

A: Simply contact us at sales@gmssupply.com, and our team will assist you through the ordering process.

Contact Us

If you're interested in learning more about the product or if you have specific inquiries, please reach out to us today.

At GMS, we aim to attract key players in the oil and gas drilling industry, including drilling contractors, equipment distributors, by offering high-quality, reliable products.

Learn about our latest products and discounts through SMS or email