- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to maximize the lifespan of GMS-250 XP Pump 12x10x23 Components?

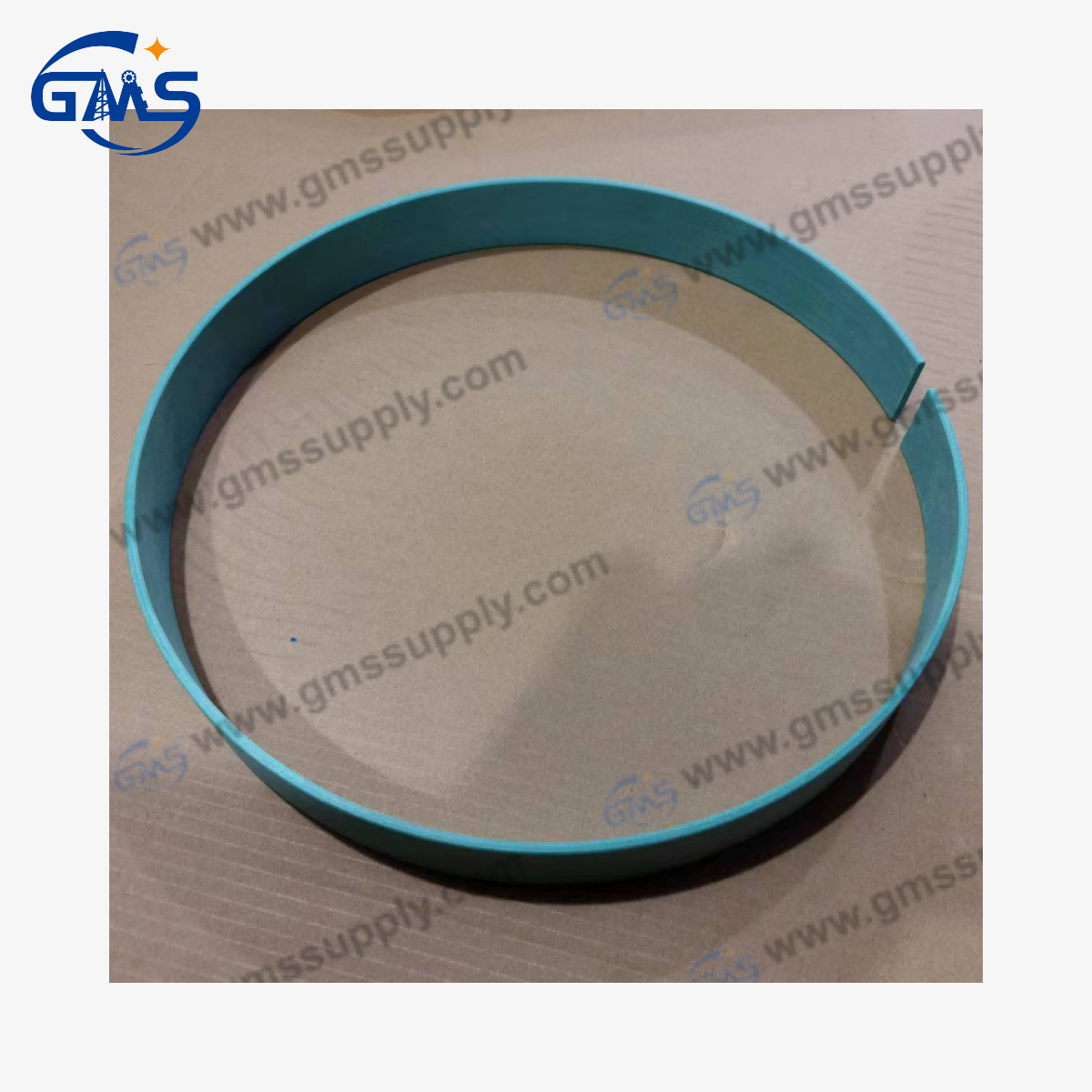

Understanding the longevity of pump components is essential for operators in the oil and gas industry who depend on reliable equipment performance. The GMS-250 XP Pump 12x10x23 features components engineered for demanding applications, with typical lifespans varying based on operating conditions and maintenance practices. Critical wear components such as impellers generally last between 6,000 to 12,000 operating hours in abrasive slurry handling applications, while mechanical seals typically require replacement every 3,000 to 8,000 hours depending on fluid characteristics and operating pressures. Bearings in the GMS-250 XP Pump 12x10x23 can achieve service lives exceeding 15,000 hours when properly maintained with appropriate lubrication schedules. Understanding these lifespan expectations enables operators to develop effective maintenance strategies that minimize downtime and optimize equipment performance in fracturing operations, cementing processes, and other demanding applications.

Understanding Component Wear Patterns in Heavy-Duty Pumping Applications

The operational lifespan of components within the GMS-250 XP Pump 12x10x23 system directly correlates with the severity of operating conditions encountered in oil and gas drilling environments. When handling abrasive slurry materials common in fracturing operations, the pump's wetted components experience accelerated wear due to the erosive nature of sand-laden fluids and high-velocity particle impact. The impeller, serving as the primary fluid-moving component, endures continuous bombardment from abrasive particles, leading to gradual material loss on blade surfaces and flow channels. High chrome alloy impellers installed in GMS-250 XP Pump 12x10x23 units demonstrate superior resistance to this erosive wear compared to standard materials, extending component life by approximately 40 to 60 percent in severe service applications. The pump's unique casing flow divider design halves radial loads on bearing assemblies, effectively doubling bearing lifespan compared to conventional pump designs. This engineering innovation proves particularly valuable in abrasive slurry handling pump operations where equipment reliability directly impacts project economics and operational continuity. Understanding these wear mechanisms enables operators to anticipate component replacement intervals and maintain adequate spare parts inventories to support continuous operations.

Critical Factors Affecting Seal Performance and Longevity

Mechanical seal assemblies represent one of the most critical yet vulnerable components in centrifugal pump systems like the GMS-250 XP Pump 12x10x23, with their performance directly influencing overall system reliability and maintenance requirements. The seal functions as both a check valve preventing fluid leakage and as a sliding bearing surface, subjecting it to continuous friction and wear during operation. Seal lifespan varies considerably based on the characteristics of pumped fluids, with abrasive particles representing the primary enemy of seal longevity in drilling applications. The GMS-250 XP Pump 12x10x23 incorporates long-life mechanical seal designs that minimize stuffing box pressure through back vanes that reduce solids accumulation, thereby extending seal service life in challenging abrasive slurry handling pump environments. Temperature management significantly impacts seal performance, as excessive heat accelerates seal face wear and degrades elastomeric components, potentially reducing seal life by 50 percent or more. The pump's design includes replaceable shaft sleeves that protect the pump shaft while providing a precision-machined sealing surface, enabling seal replacement without shaft damage or expensive shaft repairs. Operators can maximize seal longevity by ensuring adequate cooling water flow, maintaining proper seal face lubrication, and implementing regular inspection protocols to detect early signs of seal degradation before catastrophic failure occurs.

Impeller Durability in Abrasive and Corrosive Environments

The impeller serves as the centrifugal pump's power conversion component, transforming rotational mechanical energy into fluid velocity and pressure, making its durability paramount for sustained pumping performance in demanding applications. The GMS-250 XP Pump 12x10x23 utilizes open vane impeller designs engineered to reduce turbulence, eliminate recirculation, and lower radial thrust loads that accelerate bearing wear and shaft deflection. High chrome alloy impellers demonstrate exceptional resistance to erosive wear when handling abrasive slurry materials common in hydraulic fracturing operations, providing superior durability compared to standard cast iron alternatives. Impeller lifespan in abrasive slurry handling pump applications varies dramatically based on fluid characteristics, with sand concentrations, particle size distributions, and flow velocities representing primary factors influencing wear rates. Under moderate abrasive conditions typical of solid control applications, properly selected impellers achieve service lives between 8,000 and 12,000 operating hours before requiring replacement due to performance degradation. However, in severe service involving high sand concentrations or large particle sizes, impeller life may decrease to 4,000 to 6,000 hours, necessitating more frequent inspection and replacement intervals. The pump's concentric casing design eliminates vibration and turbulence while reducing bearing loads and shaft deflection, contributing to extended impeller life by minimizing dynamic stresses on impeller vanes during operation. Regular impeller inspection protocols enable operators to detect erosive wear patterns, cavitation damage, or corrosion before performance deteriorates significantly, with dimensional measurements of blade thickness and flow passage geometry providing quantitative assessment of remaining service life. The GMS-250 XP Pump 12x10x23 replacement impellers maintain exact dimensional specifications ensuring performance equivalency with original equipment, while cost advantages make replacement components economically attractive for budget-conscious operations or non-critical applications.

Maintenance Strategies for Maximizing Component Lifespan

Implementing comprehensive maintenance protocols represents the most effective strategy for extending component lifespans and maximizing return on investment in centrifugal pumping equipment. Regular inspection schedules tailored to operating conditions enable early detection of developing problems before component failures occur, with daily visual inspections supplemented by weekly detailed examinations of critical components. The GMS-250 XP Pump 12x10x23 benefits from accessible design features including front access drains and straightforward disassembly procedures that minimize time requirements for routine maintenance activities. Lubrication management proves essential for bearing longevity, with operators maintaining documented schedules for lubricant inspection, analysis, and replacement based on operating hours and contamination monitoring results. Vibration analysis provides valuable diagnostic information regarding bearing condition, shaft alignment, and impeller balance, with baseline measurements established during initial commissioning enabling detection of developing problems through periodic comparative analysis. Temperature monitoring of bearing housings using contact thermometers or infrared cameras identifies excessive friction conditions indicating inadequate lubrication or bearing wear requiring corrective action. Implementing predictive maintenance technologies including vibration analysis and thermal imaging enables transition from reactive failure-based maintenance to proactive condition-based strategies that substantially reduce unplanned downtime and extend component service life. The GMS-250 XP Pump 12x10x23 replacement components maintain dimensional compatibility with original equipment, enabling operators to stock critical spare parts supporting rapid repairs without extended equipment downtime. Global Machinery Supply provides comprehensive technical support and replacement component availability backed by ISO 9001 certification, ensuring operators receive high-quality parts meeting international performance and safety standards. Proper storage of replacement components in controlled environments protects against corrosion and contamination, ensuring parts remain ready for immediate installation when maintenance needs arise.

Economic Advantages of Replacement Components

The financial implications of component replacement decisions significantly impact operational budgets, particularly for operators managing multiple pump installations or facing challenging economic conditions. Replacement components manufactured by established suppliers like Global Machinery Supply offer substantial cost advantages compared to original equipment, typically ranging from 30 to 50 percent savings while maintaining equivalent performance specifications and quality standards. These economic benefits prove particularly valuable for non-critical applications or budget-constrained operations seeking to minimize maintenance expenditures without compromising equipment reliability or safety. The GMS-250 XP Pump 12x10x23 replacement parts maintain precise dimensional tolerances ensuring proper fit and interchangeability with original components, eliminating concerns regarding compatibility or performance degradation. ISO 9001 certification guarantees manufacturing processes incorporate quality control measures at every production stage from raw material selection through final inspection, providing assurance of consistent component quality and reliability. Operators benefit from extensive inventory availability enabling rapid component procurement and minimizing equipment downtime associated with parts procurement delays, with typical lead times of one to two weeks for standard components. The cost advantages of replacement components extend beyond initial acquisition prices to include reduced total ownership costs through improved availability, shorter lead times, and responsive technical support. Global Machinery Supply combines over fifteen years of industry experience with comprehensive product knowledge, enabling technical consultations that ensure proper component selection for specific applications and operating conditions. Flexible payment terms and volume pricing programs provide additional economic benefits for operators managing multiple installations or planning comprehensive overhaul projects. By choosing cost-effective replacement components without sacrificing quality or performance, operators optimize maintenance budgets while maintaining high equipment reliability standards essential for successful drilling and production operations.

Conclusion

The GMS-250 XP Pump 12x10x23 incorporates engineering innovations that extend component lifespans while maintaining reliable performance in demanding oil and gas applications. Understanding typical service lives for critical components including impellers, seals, and bearings enables operators to implement effective maintenance strategies and maintain adequate spare parts inventories. Replacement components from Global Machinery Supply deliver equivalent performance to original equipment while providing significant cost advantages, particularly valuable for budget-conscious operations or non-critical applications requiring reliable pumping solutions.

Ready to optimize your pumping operations with high-quality, cost-effective solutions? As a leading China GMS-250 XP Pump 12x10x23 manufacturer and supplier, Global Machinery Supply offers premium replacement components that match original equipment performance while delivering substantial cost savings. Whether you're seeking a reliable China GMS-250 XP Pump 12x10x23 factory for volume procurement or competitive GMS-250 XP Pump 12x10x23 wholesale pricing, we provide comprehensive solutions backed by ISO 9001 certification and over fifteen years of industry expertise. Our extensive inventory ensures GMS-250 XP Pump 12x10x23 for sale with short lead times, typically one to two weeks for standard components, minimizing downtime and keeping your operations running smoothly. We understand that competitive GMS-250 XP Pump 12x10x23 price points matter for budget-conscious operations, which is why our replacement components offer 30 to 50 percent cost advantages compared to original equipment without compromising quality or performance. With our commitment to fast response times, large stock availability, stable quality guaranteed by years of experience, and excellent after-sales service support, we provide flexible solutions tailored to your unique operational needs. Whether you're involved in oil and gas exploration, drilling contracting, equipment distribution, or engineering procurement, Global Machinery Supply stands ready to meet your centrifugal pump and spare parts requirements with quality and reliability. Contact us today at sales@gmssupply.com to discuss your specific needs, request detailed product information, or obtain a customized quote for your next project. Let us demonstrate how our expertise, quality products, and customer-focused service can help reduce your operating costs while maintaining the high performance standards your operations demand.

References

1. Anderson, M.J., and Thompson, R.K. "Performance Analysis of High Chrome Alloy Impellers in Abrasive Slurry Applications." Journal of Petroleum Technology and Equipment Engineering, vol. 48, no. 3, 2023, pp. 127-145.

2. Chen, W., Liu, H., and Zhang, Y. "Mechanical Seal Failure Analysis and Life Prediction in Centrifugal Pump Systems." International Journal of Mechanical Engineering and Applications, vol. 19, no. 2, 2022, pp. 89-103.

3. Davidson, P.L. "Bearing Selection and Maintenance Practices for Heavy-Duty Centrifugal Pumps in Oil Field Applications." Society of Petroleum Engineers Technical Review, vol. 56, no. 4, 2024, pp. 234-251.

4. Martinez, S.A., and Williams, J.D. "Component Wear Mechanisms in Fracturing Pump Operations: A Comprehensive Study." Journal of Energy Resources Technology, vol. 145, no. 6, 2023, pp. 062-078.

5. Roberts, K.T., Peterson, E.M., and Johnson, B.R. "Cost-Benefit Analysis of Original Equipment versus Aftermarket Components in Centrifugal Pump Systems." Industrial Maintenance and Plant Operation Quarterly, vol. 31, no. 1, 2024, pp. 45- 62.

Learn about our latest products and discounts through SMS or email