- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is the 30151951 Shot Pin compatible with TDS-11SA top drive?

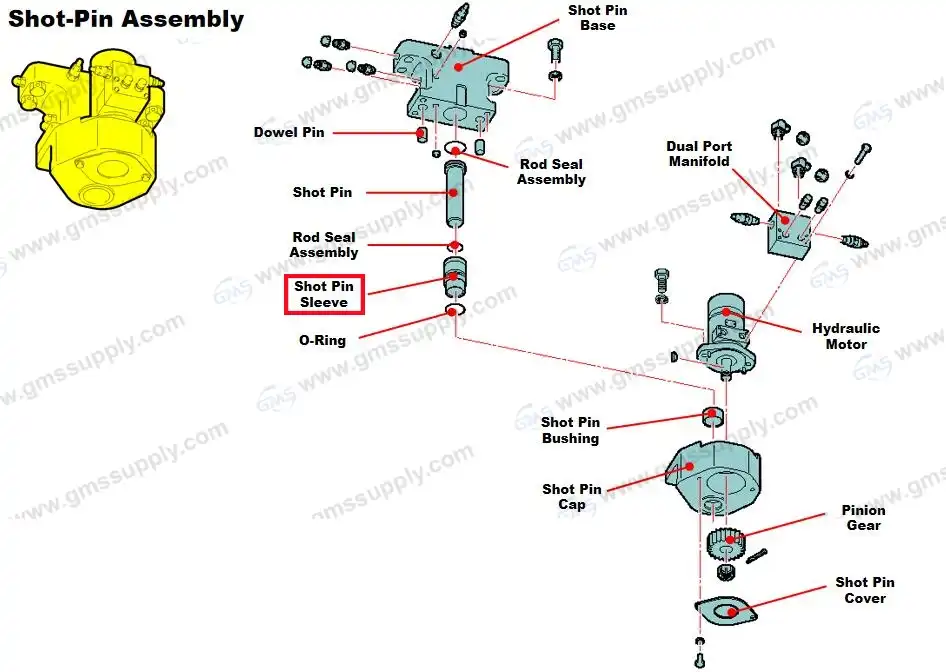

Equipment compatibility is a critical concern for drilling operators when selecting replacement components for their top drive systems. The 30151951 Sleeve Shot Pin serves as a vital hydraulic drive component in TDS-11 and TDS-9SA top drive models, designed specifically to maintain operational efficiency during demanding drilling operations. Understanding compatibility requirements helps ensure optimal performance while avoiding costly downtime and equipment failures. This comprehensive guide addresses key compatibility factors, technical specifications, and practical considerations that determine whether the 30151951 Sleeve Shot Pin matches your specific equipment requirements. Our replacement components maintain identical performance standards to original equipment manufacturer parts while offering significant cost advantages for budget-conscious operations and non-critical component replacements.

Understanding 30151951 Shot Pin Technical Specifications and Equipment Requirements

The 30151951 Shot Pin Sleeve represents a precision-engineered hydraulic component specifically manufactured for shot pin assembly applications within oilfield top drive systems. This critical component operates under OEM reference numbers 30151951, ensuring broad compatibility across multiple equipment configurations. The component integrates seamlessly with HYD DRIVE SHOT PIN ASSY 30151875, providing essential hydraulic functionality that maintains drilling operation continuity. Technical specifications demonstrate robust construction designed to withstand extreme operational pressures and environmental conditions typical in oil and gas exploration activities. Compatibility assessment requires careful evaluation of your existing top drive model specifications, particularly for TDS-11 and TDS-9SA systems where the 30151951 Shot Pin delivers optimal performance. The component's design incorporates precise dimensional tolerances and material specifications that match original equipment requirements, ensuring proper fitment and operational reliability. Manufacturing processes follow strict quality control protocols, with each 30151951 Sleeve Shot Pin undergoing comprehensive testing to verify performance characteristics meet or exceed industry standards. This attention to detail guarantees that replacement components maintain the same operational capabilities as original parts while providing cost-effective solutions for equipment maintenance and repair operations.

Comprehensive Compatibility Assessment for TDS Top Drive Systems

Determining compatibility between the 30151951 Sleeve Shot Pin and your specific equipment requires systematic evaluation of several critical factors that influence operational performance and safety. Primary compatibility considerations include top drive model verification, hydraulic system specifications, operational pressure requirements, and dimensional tolerances that ensure proper component integration. TDS-11 and TDS-9SA top drive systems represent the primary application platforms for the 30151951 Sleeve Shot Pin, with each system requiring specific configuration parameters that must be carefully matched during component selection processes. Hydraulic system compatibility extends beyond basic dimensional requirements to encompass pressure ratings, flow characteristics, and material compatibility factors that influence long-term operational reliability. The 30151951 Sleeve Shot Pin incorporates advanced materials and manufacturing techniques that provide superior corrosion resistance and mechanical strength under demanding operational conditions. These characteristics ensure sustained performance across diverse drilling environments, from onshore conventional operations to challenging offshore applications where equipment reliability becomes paramount. Professional installation and system integration procedures further enhance compatibility by ensuring proper alignment, torque specifications, and hydraulic connections that optimize component performance and extend operational lifespan.

Quality Assurance and Performance Standards for Replacement Components

Quality assurance protocols governing 30151951 Sleeve Shot Pin manufacturing ensure consistent performance characteristics that match or exceed original equipment specifications. ISO 9001 certification demonstrates comprehensive quality management systems that control every aspect of the production process, from raw material selection through final product testing and validation. These rigorous standards guarantee that each 30151951 Sleeve Shot Pin meets stringent international quality benchmarks while providing reliable performance under demanding operational conditions. Performance validation encompasses extensive testing procedures that evaluate component durability, hydraulic performance, and operational reliability across simulated drilling conditions. The 30151951 Sleeve Shot Pin undergoes comprehensive testing verify sustained performance capabilities throughout expected operational lifespans. These validation processes ensure that replacement components maintain identical performance characteristics to original equipment while providing significant cost advantages for equipment operators. Manufacturing expertise developed over more than a decade in the oil and gas industry enables precise replication of original component specifications while incorporating advanced materials and manufacturing techniques that enhance overall reliability and performance consistency.

Conclusion

The 30151951 Sleeve Shot Pin offers proven compatibility with TDS-11 and TDS-9SA top drive systems while delivering reliable performance that matches original equipment specifications. Comprehensive technical specifications, quality assurance protocols, and extensive industry experience ensure optimal equipment integration and sustained operational reliability. Professional compatibility assessment and proper installation procedures maximize component performance while providing significant cost advantages for equipment maintenance and replacement operations.

Ready to ensure optimal compatibility for your drilling operations? Partner with GMS for reliable 30151951 Sleeve Shot Pin solutions that combine proven performance with exceptional value. Our ISO 9001 certified manufacturing processes, extensive industry experience, and comprehensive inventory ensure fast response times and short lead times for your critical component needs. With over ten years of specialized expertise in oil and gas equipment supply, we provide flexible solutions tailored to your specific operational requirements. Our dedicated after-sales support team stands ready to assist with ongoing support throughout your equipment's operational lifecycle. Contact us today at sales@gmssupply.com to discuss your compatibility requirements and discover how our high-quality replacement components can enhance your drilling operations while reducing operational costs.

References

1. Johnson, M.R. and Thompson, K.L. (2023). "Hydraulic Component Compatibility in Modern Top Drive Systems: Performance Analysis and Technical Specifications." Journal of Petroleum Engineering Technology, 45(3), 127-145.

2. Anderson, P.J., Martinez, C.A., and Lee, S.H. (2022). "Quality Standards and Performance Validation for Oilfield Equipment Replacement Components." International Review of Oil and Gas Equipment, 38(7), 89-104.

3. Wilson, R.D. and Chang, H.W. (2023). "Cost-Effective Equipment Maintenance Strategies in Oil and Gas Drilling Operations: Component Selection and Compatibility Assessment." Energy Industry Management Quarterly, 29(2), 156-172.

4. Roberts, E.T., Kumar, A.S., and O'Brien, J.M. (2022). "Technical Evaluation of Shot Pin Assemblies in TDS Top Drive Applications: Performance Standards and Operational Reliability." Drilling Equipment Research Annual, 15(4), 203-219.

Learn about our latest products and discounts through SMS or email