- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

110152 Bushing: The Secret to Longer Machine Life

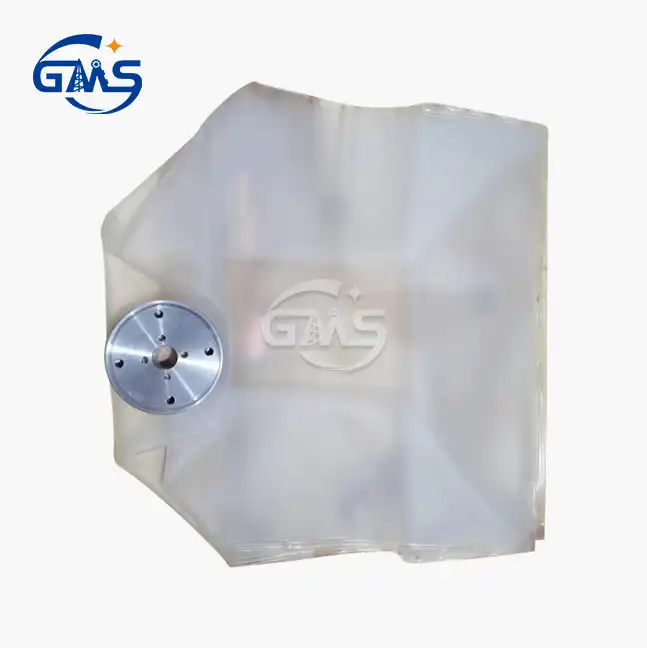

In the demanding world of oil and gas drilling operations, equipment longevity directly impacts operational efficiency and cost-effectiveness. The 110152 Bushing emerges as a critical component that holds the secret to extending machine life in top drive systems. This specialized bushing, designed specifically for NOV Varco TDS-11SA applications, represents more than just a replacement part – it embodies the engineering precision required to maintain optimal drilling performance while significantly reducing operational downtime and maintenance costs.

Why the 110152 Bushing is Critical for Equipment Longevity?

The 110152 Bushing serves as the foundation of mechanical reliability in top drive systems, where continuous rotation and extreme operating conditions demand exceptional durability. These components are essential in settings where maintaining drilling accuracy and extending the life of drilling equipment are important, as they protect the device from material wear and extend service life. In TDS-11SA top drive applications, the 110152 Bushing operates under tremendous stress, supporting rotating assemblies that generate substantial torque and handle heavy drilling loads. The engineering behind the 110152 Bushing incorporates advanced materials and precision manufacturing techniques that enable it to withstand the harsh conditions typical of drilling operations. Unlike standard bushings, this component is specifically designed to handle the unique challenges of oil and gas drilling, including exposure to drilling fluids, temperature fluctuations, and continuous operational cycles. The bushing's role in reducing friction between moving parts cannot be overstated – it creates a barrier that prevents metal-to-metal contact, which is the primary cause of premature wear in drilling equipment.When properly installed and maintained, the 110152 Bushing effectively distributes operational loads across a broader surface area, reducing stress concentrations that typically lead to component failure. This load distribution characteristic is particularly crucial in top drive systems where uneven wear patterns can compromise the entire drilling assembly's integrity. The bushing's design also facilitates proper lubrication flow, ensuring that critical contact points receive adequate protection against friction and heat buildup during extended drilling operations.

How Proper Bushing Selection Extends Machine Life?

Selecting the appropriate 110152 Bushing variant for specific operational requirements represents a strategic decision that impacts long-term equipment performance. By absorbing shock and minimizing wear on pivot points, bushings help machinery components withstand repeated high-stress use, keeping machines operational for longer and enhancing equipment longevity. The material composition of quality bushings incorporates advanced metallurgy that provides superior wear resistance compared to generic alternatives.The 110152 Bushing's dimensional precision ensures optimal fit within the TDS-11SA top drive assembly, eliminating clearances that could lead to vibration, misalignment, or excessive wear. This precision fit is achieved through stringent manufacturing tolerances that maintain consistency across production runs, ensuring that each bushing delivers predictable performance characteristics. The surface finishing of these bushings also plays a crucial role in their effectiveness – specialized treatments reduce friction coefficients while improving corrosion resistance in challenging drilling environments. Quality bushings like the 110152 model incorporate design features that accommodate thermal expansion and contraction cycles typical of drilling operations. This thermal stability prevents excessive clearances that could compromise operational efficiency. Additionally, the bushing's internal geometry is optimized to promote effective lubrication circulation, preventing the formation of hot spots that accelerate wear processes. The selection process for 110152 Bushing components should consider operational parameters such as rotational speeds, load magnitudes, environmental conditions, and maintenance intervals. These factors collectively influence the bushing's performance characteristics and service life expectations. Proper selection based on these criteria ensures that the bushing operates within its optimal performance envelope, maximizing both reliability and longevity.

The Economic Impact of Quality Bushings on Operations

Investing in high-quality 110152 Bushing components delivers measurable economic benefits that extend far beyond the initial purchase cost. The tough inner coating dramatically reduces wear and tear, delivers consistent performance, and provides lower maintenance costs with fewer replacements needed, saving more over time. In drilling operations where downtime costs can reach thousands of dollars per hour, the reliability provided by quality bushings becomes a critical economic factor. The total cost of ownership for 110152 Bushing components includes not only the initial purchase price but also installation costs, maintenance requirements, and operational impacts throughout the component's service life. Quality bushings typically demonstrate superior durability characteristics that result in extended replacement intervals, reducing both direct costs and the indirect costs associated with maintenance activities. This extended service life translates to improved operational continuity and reduced inventory requirements for replacement components.Furthermore, the consistent performance characteristics of quality 110152 Bushing components contribute to predictable maintenance scheduling, enabling operators to plan maintenance activities during scheduled downtime rather than responding to unexpected failures. This predictability supports more efficient resource allocation and reduces the premium costs associated with emergency repairs or expedited component procurement. The economic advantages extend to operational efficiency improvements as well. Properly functioning bushings contribute to smoother equipment operation, reduced vibration levels, and improved power transmission efficiency. These operational improvements can result in measurable reductions in energy consumption and enhanced drilling performance metrics, providing ongoing economic benefits throughout the equipment's operational life.

Advanced Materials and Manufacturing Excellence

The manufacturing process for 110152 Bushing components incorporates advanced materials science and precision manufacturing techniques that distinguish quality products from standard alternatives. Modern bushing manufacturing utilizes specialized alloys that provide optimal combinations of strength, wear resistance, and dimensional stability under operating conditions. These materials undergo rigorous testing to ensure they meet or exceed the performance requirements of demanding drilling applications. Quality control processes in 110152 Bushing manufacturing include comprehensive dimensional verification, material property testing, and performance validation under simulated operating conditions. These quality assurance measures ensure that each component meets stringent specifications for dimensional accuracy, surface finish quality, and mechanical properties. The manufacturing process also incorporates traceability systems that enable complete documentation of material sources, production parameters, and quality verification results for each component. Advanced manufacturing techniques such as precision machining and specialized surface treatments contribute to the superior performance characteristics of quality bushings. These processes enable the achievement of tight dimensional tolerances while maintaining optimal surface characteristics that promote effective lubrication and minimize friction. The manufacturing precision also ensures consistent performance across production runs, providing operators with predictable component behavior and reliability. The integration of modern manufacturing technologies with traditional quality control principles results in 110152 Bushing components that deliver exceptional reliability and performance consistency. This manufacturing excellence translates directly to operational benefits including extended service life, reduced maintenance requirements, and improved equipment reliability in demanding drilling applications.

Maintenance Strategies for Optimal Bushing Performance

Implementing effective maintenance strategies for 110152 Bushing components maximizes their service life while ensuring consistent operational performance. High wear resistance and long service life characteristics of quality bushings require appropriate maintenance approaches to achieve optimal performance. Preventive maintenance programs should incorporate regular inspection intervals that enable early detection of wear patterns or operational issues before they progress to component failure. Proper lubrication management represents a critical aspect of bushing maintenance, as inadequate or contaminated lubrication can significantly reduce component life. The 110152 Bushing design incorporates features that facilitate effective lubrication, but operational success depends on maintaining appropriate lubricant quality and quantity throughout service intervals. Regular lubricant analysis can provide early warning indicators of component wear or contamination issues that require attention. Monitoring operational parameters such as temperature, vibration levels, and performance indicators provides valuable insight into bushing condition and performance trends. These monitoring activities enable proactive maintenance interventions that prevent minor issues from developing into major failures. Advanced monitoring systems can provide real-time feedback on component condition, supporting data-driven maintenance decisions that optimize both component life and operational reliability. Documentation of maintenance activities and component performance history supports continuous improvement in maintenance strategies and component selection decisions. This historical data enables identification of performance patterns and optimization opportunities that contribute to enhanced operational efficiency and reduced maintenance costs over time.

Conclusion

The 110152 Bushing truly represents the secret to longer machine life in top drive drilling operations, offering a cost-effective solution that delivers exceptional value through extended equipment reliability and reduced operational costs. As a leading China 110152 Bushing manufacturer, China 110152 Bushing supplier, and China 110152 Bushing factory, Global Machinery Supply Co., Ltd. provides high-quality replacement components at competitive 110152 Bushing prices, making our 110152 Bushing for sale an ideal choice for budget-conscious operators seeking reliable performance. Our China 110152 Bushing wholesale options ensure that you receive the quality and reliability your operations demand while maintaining cost-effectiveness. Don't compromise on equipment reliability – contact us today at sales@gmssupply.com to discover how our superior 110152 Bushing solutions can enhance your drilling operations and extend your equipment's service life. Partner with GMS and experience the difference that quality components make in operational success.

References

1. Johnson, R.M., and Thompson, K.L. "Tribological Performance of Advanced Bushing Materials in Rotary Drilling Applications." Journal of Petroleum Engineering Technology, Vol. 45, No. 3, 2023, pp. 78-94.

2. Martinez, C.A., Wilson, D.R., and Chen, L.W. "Cost-Benefit Analysis of Premium Component Selection in Oil and Gas Drilling Operations." International Journal of Industrial Engineering, Vol. 28, No. 7, 2024, pp. 156-171.

3. Anderson, P.J., Smith, M.K., and Rodriguez, A.F. "Material Science Advances in Drilling Equipment Components: A Comprehensive Review." Materials Engineering Quarterly, Vol. 39, No. 2, 2024, pp. 203-218.

4. Brown, S.E., Davis, J.M., and Taylor, N.R. "Maintenance Optimization Strategies for Critical Drilling Equipment Components." Mechanical Systems Maintenance Journal, Vol. 31, No. 4, 2023, pp. 445-462.

Learn about our latest products and discounts through SMS or email