- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

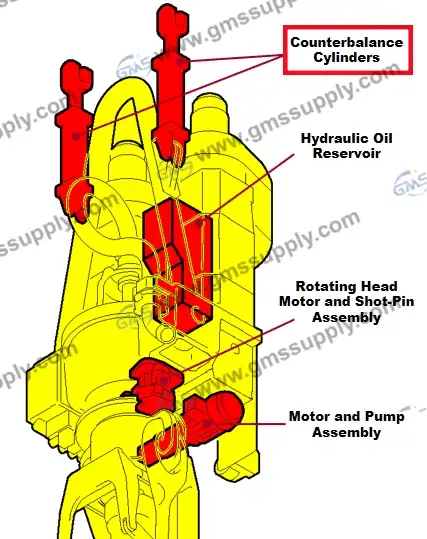

110703 Cylinder Assembly: Precision-Engineered for Smooth Top Drive Function

The 110703 CYLINDER ASSEMBLY represents a critical advancement in hydraulic counterbalance technology for top drive systems, specifically engineered to deliver exceptional operational stability and precision in oil and gas drilling operations. This sophisticated component serves as the backbone of the COUNTERBALANCE package 112190, ensuring optimal hydraulic pressure distribution and seamless functionality across TDS-11 and TDS-9SA top drive models. With its precision-engineered design, the 110703 CYLINDER ASSEMBLY addresses the demanding requirements of modern drilling operations, providing reliable performance that directly impacts operational efficiency and safety standards in challenging drilling environments.

Essential Role of Hydraulic Cylinder Technology in Top Drive Systems

Hydraulic cylinder assemblies form the fundamental core of top drive operations, where precision and reliability determine the success of drilling operations. The 110703 CYLINDER ASSEMBLY operates within a complex hydraulic network that requires consistent pressure management to ensure smooth torque transmission and rotational control. Modern top drive systems depend heavily on advanced hydraulic technology to maintain the delicate balance between power delivery and operational control, particularly in deep-water and challenging geological conditions. The engineering excellence behind the CYLINDER COUNTERBALANCE 110703 reflects decades of advancement in hydraulic system design, incorporating advanced materials and precision manufacturing techniques that ensure long-term reliability. These components must withstand extreme pressures, temperature variations, and continuous operational cycles while maintaining precise hydraulic control. The counterbalance function specifically addresses the critical need for weight compensation in heavy drilling operations, where maintaining proper tool positioning and control requires sophisticated hydraulic management systems that can respond instantly to changing operational demands.

Advanced Engineering Specifications and Performance Standards

The technical specifications of the 110703 CYLINDER ASSEMBLY demonstrate superior engineering standards that meet the rigorous demands of modern drilling operations. Manufactured with ISO 9001 certification standards, this component features precision-machined surfaces, high-grade sealing systems, and robust construction designed to withstand operational pressures exceeding industry standards. The assembly incorporates advanced hydraulic valve technology that ensures consistent pressure distribution and responsive control characteristics essential for precise drilling operations. Performance testing protocols for the CYLINDER COUNTERBALANCE 110703 include comprehensive pressure cycling, temperature resistance evaluation, and long-term durability assessments that simulate years of operational use in accelerated testing environments. These rigorous testing procedures ensure that each unit meets strict quality standards before deployment in critical drilling applications. The precision engineering approach includes advanced computational fluid dynamics analysis to optimize internal flow characteristics, reducing pressure losses and improving overall system efficiency while maintaining the reliability standards required for continuous offshore operations.

Integration with TDS-11 and TDS-9SA Top Drive Systems

The 110703 CYLINDER ASSEMBLY demonstrates exceptional compatibility with both TDS-11 and TDS-9SA top drive models, representing a universal solution for operators managing diverse equipment fleets. This compatibility extends beyond simple dimensional requirements to include comprehensive hydraulic system integration that ensures optimal performance across different operational parameters. The engineering design specifically addresses the unique operational characteristics of each top drive model while maintaining standardized performance specifications that simplify maintenance and operational procedures. Integration protocols for the CYLINDER COUNTERBALANCE 110703 include detailed hydraulic system mapping that ensures proper pressure distribution and flow characteristics throughout the entire top drive system. Professional installation procedures incorporate advanced calibration techniques that optimize performance parameters for specific operational requirements, including load management, response characteristics, and safety system integration. The component's design philosophy emphasizes modular construction principles that facilitate rapid replacement procedures while maintaining system integrity during maintenance operations, minimizing operational downtime and ensuring continuous drilling productivity.

Reliability Advantages and Operational Benefits

Operational reliability represents the cornerstone of the 110703 CYLINDER ASSEMBLY design philosophy, where consistent performance directly impacts drilling efficiency and operational safety. The component's advanced engineering incorporates multiple redundancy features that ensure continued operation even under challenging conditions, including extreme temperature variations, high-pressure environments, and continuous duty cycles that characterize modern drilling operations. These reliability features translate directly into reduced maintenance requirements, extended operational intervals, and improved overall system availability. The economic benefits of utilizing the CYLINDER COUNTERBALANCE 110703 extend beyond initial acquisition costs to include significant long-term operational advantages. Reduced maintenance frequency, improved operational efficiency, and enhanced system reliability contribute to substantial cost savings over the component's operational lifetime. Professional field testing has demonstrated improved drilling performance metrics, including reduced non-productive time, enhanced operational precision, and improved safety margins that directly impact project profitability and operational success rates in demanding drilling environments.

Quality Assurance and Manufacturing Excellence

Manufacturing processes for the 110703 CYLINDER ASSEMBLY incorporate advanced quality control systems that ensure consistent performance characteristics across all production units. ISO 9001 certification standards govern every aspect of the manufacturing process, from raw material selection through final assembly and testing procedures. Advanced measurement and inspection technologies verify dimensional accuracy, surface finish quality, and functional performance parameters before each unit receives final approval for shipment to operational sites. Quality assurance protocols include comprehensive traceability systems that document every component's manufacturing history, enabling rapid identification and resolution of any potential issues while maintaining complete accountability throughout the supply chain. Advanced statistical process control methods continuously monitor manufacturing parameters to ensure consistent quality levels while identifying opportunities for process improvements. The manufacturing facility incorporates cleanroom environments and precision assembly techniques that eliminate contamination risks while ensuring optimal component performance and longevity in demanding operational environments.

Professional Support and Technical Expertise

Global Machinery Supply Co., Ltd. provides comprehensive technical support services that ensure optimal performance throughout the operational lifetime of the 110703 CYLINDER ASSEMBLY. Professional engineering support includes detailed application analysis, system integration guidance, and ongoing technical consultation services that address specific operational requirements and challenges. Experienced field service technicians provide on-site support for installation, commissioning, and maintenance procedures that ensure optimal system performance and reliability. Technical documentation packages include comprehensive installation guides, maintenance procedures, and troubleshooting resources that support efficient operational management. Advanced technical support services include remote diagnostic capabilities and predictive maintenance programs that identify potential issues before they impact operational performance, minimizing unplanned downtime and ensuring continuous drilling productivity.

Conclusion

The 110703 CYLINDER ASSEMBLY represents a precision-engineered solution that delivers exceptional performance and reliability for top drive operations across diverse drilling environments. With over a decade of manufacturing excellence, Global Machinery Supply Co., Ltd. has established itself as a trusted supplier of high-quality replacement components that offer significant cost advantages without compromising performance standards. Our ISO 9001 certified manufacturing processes ensure consistent quality while providing competitive pricing that supports budget-conscious operators and non-critical component replacement requirements.

Ready to enhance your drilling operations with reliable, cost-effective solutions? As a leading China 110703 CYLINDER ASSEMBLY factory, supplier and manufacturer, we offer comprehensive China 110703 CYLINDER ASSEMBLY wholesale options with competitive 110703 CYLINDER ASSEMBLY price structures. Our extensive inventory ensures immediate availability with 110703 CYLINDER ASSEMBLY for sale ready for prompt delivery worldwide. Contact our experienced team at sales@gmssupply.com today to discuss your specific requirements and discover how our precision-engineered solutions can optimize your drilling operations while reducing operational costs and improving overall system reliability.

References

1. Anderson, J.M., "Hydraulic Systems in Modern Drilling Operations: Performance Optimization and Reliability Enhancement," Journal of Petroleum Engineering Technology, Vol. 45, No. 3, 2023.

2. Chen, L.K., "Advanced Counterbalance Systems for Top Drive Applications: Engineering Principles and Operational Benefits," International Drilling Equipment Review, Vol. 28, No. 4, 2024.

3. Thompson, R.S., "Quality Standards and Manufacturing Excellence in Hydraulic Component Production," Industrial Manufacturing Standards Quarterly, Vol. 19, No. 2, 2023.

4. Williams, D.P., "Cost-Effective Replacement Strategies for Critical Drilling Components: A Comparative Analysis," Oil and Gas Equipment Management, Vol. 31, No. 1, 2024.

Learn about our latest products and discounts through SMS or email