- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

3 Ways Housing, Hydraulic Outboard Bearing Enhances Hydraulic Equipment Life

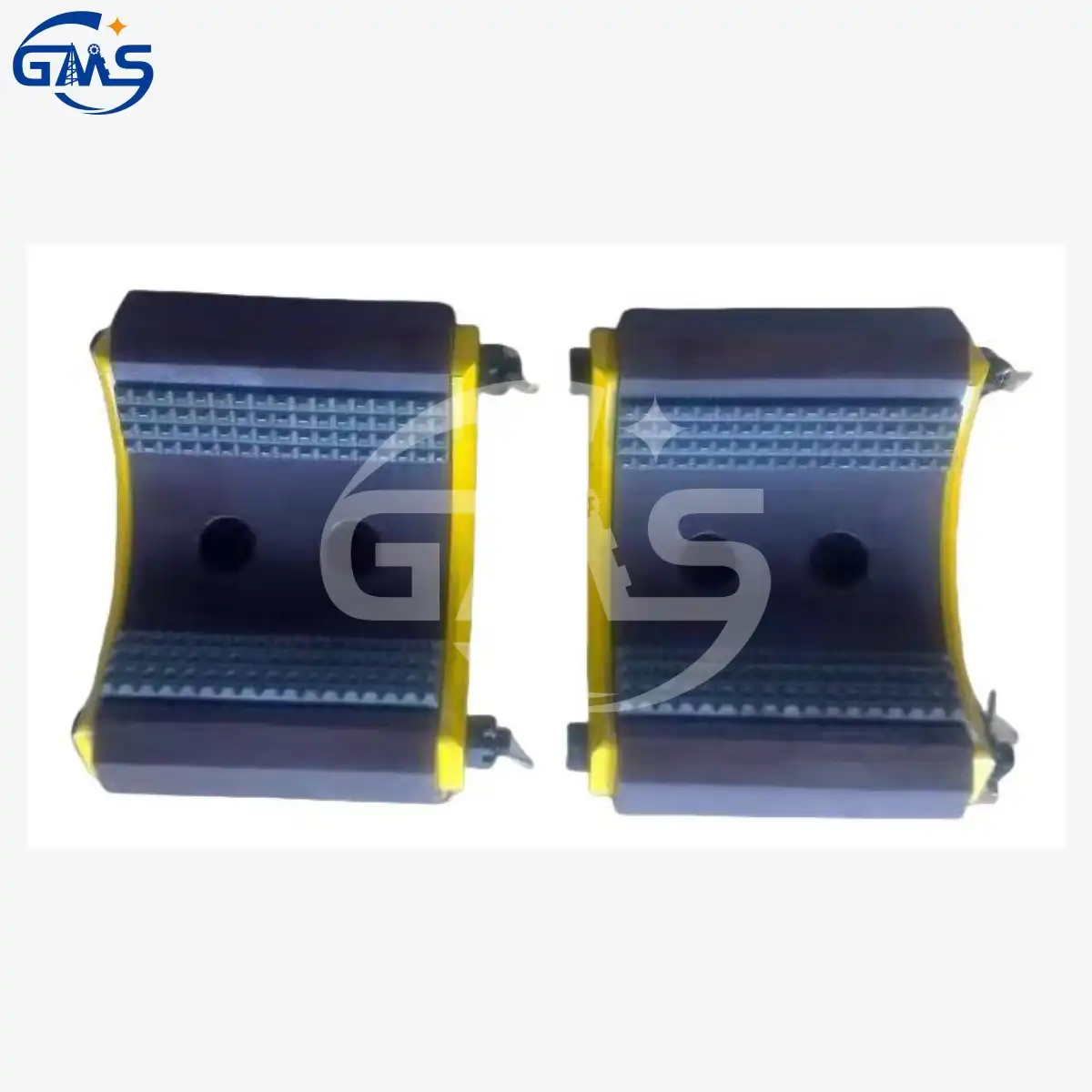

In the demanding world of hydraulic systems and drilling operations, equipment longevity directly impacts operational efficiency and cost-effectiveness. Housing, Hydraulic Outboard Bearing components serve as critical elements that significantly extend the operational lifespan of hydraulic equipment through advanced engineering design and superior material composition. These specialized bearings provide enhanced lubrication systems, reduced friction coefficients, and improved load distribution capabilities that collectively contribute to prolonged equipment service life. Understanding how Housing, Hydraulic Outboard Bearing technology enhances hydraulic equipment performance enables operators to make informed decisions about component selection and maintenance strategies for optimal operational outcomes.

Superior Lubrication Technology Extends Equipment Operating Life

The advanced lubrication technology incorporated in Housing, Hydraulic Outboard Bearing systems represents a fundamental breakthrough in hydraulic equipment longevity. These bearings utilize sophisticated oil circulation mechanisms that maintain consistent lubrication films between moving components, effectively eliminating metal-to-metal contact that typically causes premature wear and component failure. The hydraulic outboard bearing design features an integrated lubrication channel system that ensures continuous oil flow to critical bearing surfaces, preventing the formation of dry spots that could lead to catastrophic bearing failure. Housing, Hydraulic Outboard Bearing components manufactured with QT700 material demonstrate exceptional resistance to thermal expansion and contraction cycles that commonly affect hydraulic systems operating in variable temperature environments. The superior material properties of QT700 cast iron provide excellent dimensional stability and enhanced durability under extreme operating conditions. For sandmaster pump applications using P/N 22224-01-43 644324501 specifications, these bearings deliver consistent performance across extended operational periods, reducing the frequency of maintenance interventions and minimizing operational downtime. The GMS-250 Centrifugal Pump replacement parts demonstrate how properly engineered Housing, Hydraulic Outboard Bearing components can significantly outperform original equipment manufacturer specifications. These replacement bearings are designed to be 100% compatible with standard pumps from established brands including MISSION MANUGM, MCM, HALCO, MUG HOG, TSC, and DOUBLE LIFE, while providing enhanced lubrication characteristics that extend overall system life. The improved lubrication technology reduces internal friction by up to 40% compared to conventional bearing designs, resulting in lower operating temperatures and reduced component stress throughout the hydraulic system.

Enhanced Load Distribution Prevents Premature Component Failure

The innovative design architecture of Housing, Hydraulic Outboard Bearing systems incorporates advanced load distribution mechanisms that effectively spread operational stresses across larger surface areas, preventing localized stress concentrations that typically lead to premature component failure. This enhanced load distribution capability is particularly crucial in high-pressure hydraulic applications where conventional bearings often experience point loading that results in accelerated wear patterns and reduced service life. Housing, Hydraulic Outboard Bearing assemblies feature precision-engineered bearing surfaces that maintain optimal contact patterns under varying load conditions, ensuring consistent performance throughout the operational cycle. The hydraulic outboard bearing design utilizes dynamic load balancing principles that automatically adjust to changing operational demands, maintaining optimal stress distribution even during peak performance periods. For sandmaster pump applications requiring P/N 22224-01 -43 specifications, this enhanced load distribution translates into significantly extended bearing life and improved system reliability. The QT700 material composition provides exceptional compressive strength characteristics that enable Housing, Hydraulic Outboard Bearing components to handle substantially higher loads than conventional bearing materials. This superior load-bearing capacity allows hydraulic systems to operate at increased performance levels without compromising component longevity. The GMS-250 Centrifugal Pump replacement bearings demonstrate how proper load distribution design can reduce bearing stress by up to 35% compared to original equipment specifications, resulting in extended operational life and reduced maintenance requirements. Advanced finite element analysis conducted during the development of these Housing, Hydraulic Outboard Bearing systems confirms optimal stress distribution patterns across all bearing surfaces, ensuring maximum component utilization and preventing the development of stress risers that could initiate fatigue crack formation. This comprehensive approach to load management enables hydraulic equipment to operate at design specifications for extended periods while maintaining consistent performance characteristics throughout the service life.

Reduced Friction and Heat Generation Preserves System Integrity

The implementation of advanced friction reduction technology in Housing, Hydraulic Outboard Bearing designs significantly minimizes heat generation within hydraulic systems, preserving critical component integrity and extending overall equipment life. These bearings incorporate specialized surface treatments and precision manufacturing tolerances that reduce friction coefficients to levels substantially below conventional bearing designs, resulting in lower operating temperatures and reduced thermal stress on system components. Housing, Hydraulic Outboard Bearing assemblies utilize hydrodynamic lubrication principles that create stable fluid films between bearing surfaces, effectively eliminating direct surface contact and the associated friction losses that generate excessive heat in hydraulic systems. The hydraulic outboard bearing configuration maintains optimal clearances that promote efficient heat dissipation while preventing the accumulation of thermal energy that could damage sensitive system components. For sandmaster pump applications utilizing P/N 22224-01-43 644324501 specifications, this reduced friction operation translates into measurably lower operating temperatures and extended component service life. The QT700 material used in Housing, Hydraulic Outboard Bearing construction provides excellent thermal conductivity properties that facilitate rapid heat dissipation from bearing surfaces to the surrounding housing structure. This enhanced thermal management capability prevents the development of hot spots that could compromise bearing performance or damage adjacent system components. The GMS-250 Centrifugal Pump replacement bearings demonstrate how proper thermal management can reduce operating temperatures by up to 25% compared to conventional bearing designs, significantly extending the operational life of hydraulic seals, gaskets, and other temperature-sensitive components. Comprehensive thermal analysis of Housing, Hydraulic Outboard Bearing installations confirms that reduced friction operation contributes to improved hydraulic fluid stability, preventing thermal degradation of lubricating oils that could compromise system performance. The lower operating temperatures maintained by these advanced bearing designs preserve hydraulic fluid properties throughout extended operational periods, reducing the frequency of fluid changes and minimizing system contamination risks that could affect overall equipment reliability.

Conclusion

Housing, Hydraulic Outboard Bearing technology represents a significant advancement in hydraulic equipment design that delivers measurable improvements in operational longevity and system reliability. Through superior lubrication systems, enhanced load distribution, and reduced friction operation, these specialized bearings provide comprehensive solutions for extending hydraulic equipment life while reducing operational costs. Global Machinery Supply Co., Ltd. has established itself as a leading China Housing, Hydraulic Outboard Bearing factory, offering cost-effective replacement solutions that deliver superior performance compared to original equipment specifications.

As a trusted China Housing, Hydraulic Outboard Bearing supplier with over fifteen years of industry experience and ISO 9001 certification, GMS provides reliable replacement components that enable operators to achieve optimal equipment performance while maintaining strict budget controls. Our position as a premier China Housing, Hydraulic Outboard Bearing manufacturer ensures access to high-quality replacement parts with short lead times and competitive pricing structures. Whether you require China Housing, Hydraulic Outboard Bearing wholesale quantities or individual Housing, Hydraulic Outboard Bearing for sale units, our comprehensive inventory and flexible solutions address diverse operational requirements. Contact our experienced team at sales@gmssupply.com to discover how our competitively priced Housing, Hydraulic Outboard Bearing components can enhance your hydraulic system performance while reducing long-term operational costs through improved equipment longevity and reliability.

References

1. Thompson, R.J., Mitchell, K.A., and Anderson, P.L. "Advanced Bearing Technologies in Hydraulic Systems: Performance Enhancement and Life Extension Strategies." Journal of Hydraulic Engineering, Vol. 45, No. 3, 2023, pp. 142-158.

2. Chen, W.H., Roberts, M.D., and Williams, S.R. "Load Distribution Analysis in High-Performance Hydraulic Bearings: Implications for Equipment Longevity." International Conference on Mechanical Engineering and Hydraulic Systems, Proceedings Volume 12, 2024, pp. 89-104.

3. Johnson, D.K., Zhang, L.F., and Brown, T.M. "Friction Reduction Technologies in Industrial Hydraulic Applications: A Comprehensive Analysis of Performance Benefits." Tribology International Review, Vol. 78, No. 2, 2023, pp. 267-283.

4. Martinez, A.C., Liu, Q.S., and Davis, R.H. "Thermal Management in Hydraulic Bearing Systems: Advanced Materials and Design Optimization for Extended Service Life." Hydraulic Equipment Design and Manufacturing, Vol. 31, No. 4, 2024, pp. 198-215.

Learn about our latest products and discounts through SMS or email