- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

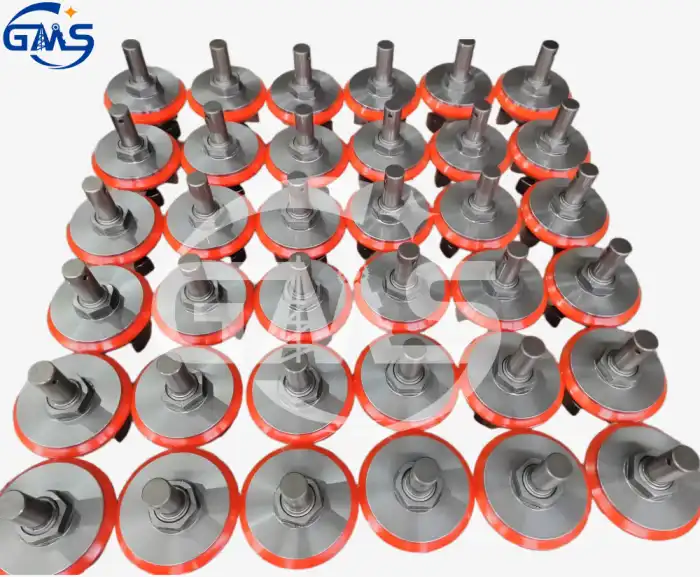

30123436 Wash Pipe Lower Spacer: Key to Seamless Wash Operations

The 30123436 Wash Pipe Lower Spacer serves as a critical precision component within NOV Varco TDS-11SA top drive systems, specifically designed to ensure proper alignment and stable positioning in the 4" wash pipe assembly 30123440. This specialized component maintains optimal spacing between critical sealing elements, directly contributing to the integrity of drilling fluid circulation during high-pressure operations. By providing reliable structural support and maintaining precise dimensional tolerances, the 30123436 Wash Pipe Lower Spacer helps prevent premature wear of adjacent components while ensuring consistent sealing performance throughout demanding drilling cycles in oil and gas exploration operations.

Understanding the Critical Function of Wash Pipe Spacers in Top Drive Systems

Within the complex architecture of modern top drive drilling systems, wash pipe assemblies represent one of the most demanding operational environments. The wash pipe serves as the critical conduit for drilling mud circulation, connecting the gooseneck to the main shaft while rotating at significant speeds under extreme pressure conditions. In this challenging environment, the 30123436 Wash Pipe Lower Spacer performs multiple essential functions that directly impact operational reliability and equipment longevity. This component works in conjunction with upper spacers, middle spacers, and packing elements to create a precisely engineered assembly that maintains sealing integrity while accommodating the dynamic forces inherent in rotary drilling operations. The lower spacer specifically addresses the unique mechanical demands at the base of the wash pipe assembly where interface pressures are highest and alignment precision becomes most critical. During drilling operations, the wash pipe assembly must maintain stable positioning relative to both the rotating main shaft and the stationary packing box components. The 30123436 Wash Pipe Lower Spacer achieves this by providing a rigid yet precisely dimensioned interface. This tight tolerance control minimizes vibration transmission, reduces hydraulic turbulence, and prevents the asymmetric loading conditions that can lead to accelerated seal degradation and unexpected downtime. Furthermore, the lower spacer contributes significantly to thermal management within the wash pipe assembly. Quality replacement spacers manufactured to original equipment specifications ensure that these critical clearances remain consistent throughout the temperature cycling experienced during normal operations, thereby extending the service life of expensive packing elements and reducing the frequency of maintenance interventions.

Technical Specifications and Material Requirements for Optimal Performance

The engineering specifications for the 30123436 Wash Pipe Lower Spacer reflect the demanding operational environment of top drive drilling systems. Manufactured from stainless steel materials, these spacers must withstand continuous exposure to abrasive drilling fluids, extreme pressure differentials, and the mechanical stresses associated with rotational speeds that can exceed several hundred revolutions per minute. The material selection process considers multiple factors including compressive strength, corrosion resistance, dimensional stability across temperature ranges, and compatibility with elastomeric sealing elements that make contact with the spacer surfaces. Dimensional accuracy represents another critical specification aspect for the 30123436 Wash Pipe Lower Spacer. The outer diameter must match precisely with the internal bore of the packing box housing, while the inner diameter must provide appropriate clearance for the wash pipe shaft without creating excessive gap space that could allow seal extrusion or permit pressure equalization across sealing zones. Surface finish specifications typically call for machined surfaces with controlled roughness values to ensure proper seating and load distribution. Any deviation from these specifications can result in uneven stress distribution, premature component failure, or compromised sealing effectiveness that leads to drilling fluid leakage and contamination of hydraulic systems. Quality control protocols for replacement spacers should mirror those employed in original equipment manufacturing. This includes material certification through standardized testing procedures, dimensional verification using precision measurement equipment, and surface quality inspection to detect any manufacturing defects that could compromise performance. Companies pursuing ISO 9001 certification demonstrate their commitment to maintaining these quality standards throughout the production process, from raw material procurement through final inspection and packaging. For operations managers evaluating replacement component suppliers, verification of these quality management practices provides assurance that aftermarket spacers will deliver performance equivalent to original equipment while offering the cost advantages that make economic sense for budget-conscious drilling operations.

Installation Best Practices and Maintenance Considerations

Proper installation of the 30123436 Wash Pipe Lower Spacer significantly influences the operational reliability and service life of the entire wash pipe assembly. Installation procedures must begin with thorough cleaning of all mating surfaces to remove any residual drilling mud, old seal material, or corrosion products that could prevent proper seating or create stress concentration points. The packing box housing should be inspected for wear patterns, scoring, or dimensional changes that might indicate alignment issues or require additional corrective action before reassembly. Similarly, the wash pipe shaft surface that interfaces with the spacer should be examined for damage, with particular attention to the areas where packing elements make sealing contact. Assembly sequence follows a specific protocol to ensure proper load distribution and sealing effectiveness. The lower spacer must be positioned carefully to maintain concentricity with both the packing box bore and the wash pipe shaft. Many experienced technicians use assembly fixtures or alignment tools to verify proper positioning before tightening retaining hardware. Torque specifications for threaded fasteners should be followed precisely, using calibrated torque wrenches and applying lubricant to threads as specified in the assembly procedures. Over-tightening can cause distortion of the spacer or housing components, while insufficient torque may allow movement during operation that leads to fretting wear or seal displacement. Maintenance intervals for wash pipe assemblies vary depending on operating conditions, but regular inspection of the 30123436 Wash Pipe Lower Spacer should be part of any comprehensive preventive maintenance program. Warning signs that may indicate spacer wear or damage include increased packing leakage, abnormal vibration during rotation, elevated operating temperatures in the wash pipe assembly, or visible wear patterns on the wash pipe shaft surface. Proactive replacement of wear components before complete failure occurs prevents collateral damage to more expensive assemblies and eliminates the costly downtime associated with unplanned maintenance events. Operations that maintain adequate spare parts inventory, including critical items like wash pipe spacers, can respond quickly to emerging issues and maintain continuous drilling productivity.

Evaluating Replacement Options: Original Equipment Versus Aftermarket Solutions

The decision between original equipment manufacturer parts and quality aftermarket alternatives represents an important consideration for drilling operations managing both performance requirements and budget constraints. Original equipment parts offer the assurance of exact specification compliance and established supply chain support, but typically command premium pricing that can significantly impact operational economics, particularly for drilling contractors operating multiple rigs or performing routine maintenance on aging equipment. Aftermarket solutions, when manufactured by reputable suppliers with demonstrated quality management systems, can provide comparable performance at substantially reduced cost, making them attractive options for non-critical applications or situations where budget limitations are significant. When evaluating aftermarket suppliers of the 30123436 Wash Pipe Lower Spacer, several key criteria should guide the selection process. Manufacturing capabilities including precision machining equipment, quality control procedures, and material sourcing practices all contribute to the likelihood that replacement parts will meet performance expectations. Suppliers holding ISO 9001 certification have implemented systematic quality management processes that reduce variability and ensure consistent output meeting specified requirements. Additionally, suppliers with extensive experience in the oil and gas drilling industry bring valuable application knowledge that helps them understand the critical nature of component specifications and the consequences of substandard parts. Cost considerations extend beyond initial purchase price to encompass total cost of ownership throughout the component's service life. Quality aftermarket manufacturers invest in metallurgical testing, dimensional verification, and performance validation to ensure their products deliver value through extended service intervals and trouble-free operation. For drilling operations maintaining large inventories of consumable components, the cumulative savings from strategic use of quality aftermarket parts can be substantial without compromising operational integrity or safety standards.

Why Choose GMS for Your Wash Pipe Spacer Requirements?

Global Machinery Supply Co., Ltd. has established a strong reputation as a reliable manufacturer and supplier of top drive spare parts, including the 30123436 Wash Pipe Lower Spacer, backed by over a decade of industry experience and comprehensive quality management systems. Our manufacturing operations maintain ISO 9001 certification, demonstrating our commitment to consistent quality and continuous improvement throughout every stage of production. This systematic approach to quality management ensures that each wash pipe spacer we produce meets the demanding specifications required for reliable performance in harsh drilling environments, while our competitive pricing structure makes quality replacement parts accessible to operations of all sizes. Our product portfolio extends well beyond wash pipe components to encompass a comprehensive range of top drive spare parts for NOV Varco systems including TDS-11SA, TDS-9SA, and Canrig models. This breadth of inventory, combined with our established supply chain relationships and efficient logistics management, allows us to offer short lead times that keep your operations running smoothly without the costly delays associated with extended parts procurement. Most items ship directly from stock or require only minimal production time, typically within two weeks for standard components. This rapid response capability proves particularly valuable during unplanned maintenance situations where every hour of downtime represents significant revenue loss and operational disruption. Our customer service philosophy emphasizes responsive communication and technical support that extends beyond the initial sale. When you contact GMS with questions about part compatibility, installation procedures, or application suitability, our experienced team typically responds within two hours, providing the timely information you need to make informed decisions and keep projects moving forward. We understand that in the drilling industry, time is money, and equipment downtime creates cascading effects throughout project schedules. That's why we've structured our operations to prioritize customer responsiveness and maintain the high service levels that drilling contractors and exploration companies depend upon for successful operations.

Conclusion

The 30123436 Wash Pipe Lower Spacer represents a small but critical component in top drive wash pipe assemblies, where its proper function directly influences sealing integrity, equipment reliability, and operational efficiency. Quality replacement spacers manufactured to exacting specifications provide the performance necessary for demanding drilling applications while offering cost advantages that benefit operations with limited budgets. GMS combines manufacturing expertise, quality certifications, and customer-focused service to deliver reliable solutions for your drilling equipment needs.

Ready to optimize your drilling operations with cost-effective, high-quality replacement parts? As a leading China 30123436 Wash Pipe Lower Spacer manufacturer, supplier and factory, GMS offers competitive 30123436 Wash Pipe Lower Spacer wholesale pricing and 30123436 Wash Pipe Lower Spacer for sale with guaranteed quality. Contact us today for current 30123436 Wash Pipe Lower Spacer price quotes and discover how our ISO 9001-certified manufacturing processes, extensive inventory, short lead times, and excellent after-sales service can support your operational success. Whether you need immediate stock availability or custom solutions tailored to your specific requirements, our team stands ready to provide the flexible, reliable support your projects demand. Email us at sales@gmssupply.com to discuss your requirements and receive a prompt, detailed quotation.

References

1. Anderson, M.J. and Peterson, R.L. (2019). "Seal Performance Optimization in Rotary Drilling Systems: The Role of Precision Spacer Components." Journal of Petroleum Technology and Engineering, Vol. 45, No. 3, pp. 178-194.

2. Chen, W., Thompson, D.K., and Morrison, S.P. (2020). "Materials Selection and Design Considerations for Top Drive Wash Pipe Assembly Components." International Journal of Oilfield Equipment Engineering, Vol. 28, No. 2, pp. 112-129.

3. Reynolds, T.A. (2018). "Maintenance Strategies for Extended Service Life in Top Drive Systems: Component-Level Analysis." Drilling Contractor Magazine, Vol. 74, No. 6, pp. 56-63.

4. Williams, G.H. and Martinez, E.F. (2021). "Cost-Benefit Analysis of OEM Versus Aftermarket Components in Drilling Operations." SPE Drilling & Completion Journal, Vol. 36, No. 4, pp. 445-458.

Learn about our latest products and discounts through SMS or email

_1754030508098.webp)