- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

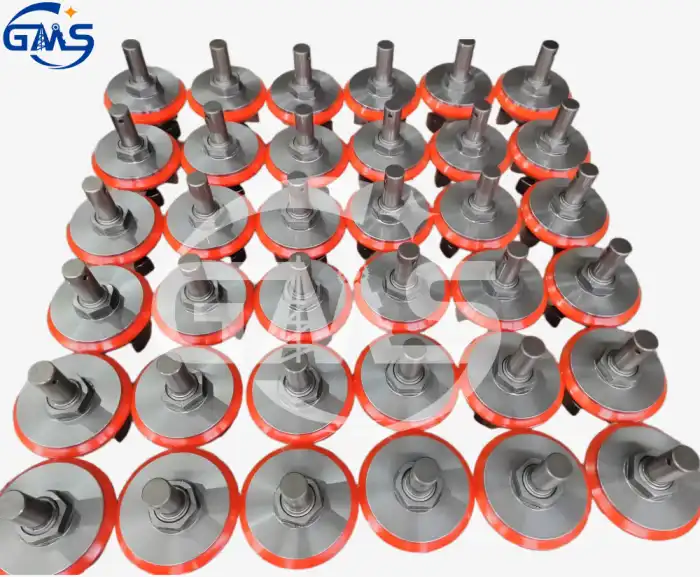

Backlash Control Solved: SHIM GEAR 120262-1 Series (120262-1 to -5) In Stock

The oil and gas drilling industry demands precision engineering components that can withstand extreme operational conditions while maintaining optimal performance. Among the critical components in top drive systems, gear shimming plays a vital role in controlling backlash and ensuring smooth power transmission. The SHIM GEAR 120262-1 series represents a comprehensive solution for backlash control challenges faced by TDS-11SA and TDS-9SA top drive systems. These precision-engineered shims, ranging from 120262-1 to 120262-5, are specifically designed to address gear alignment issues that can lead to premature wear, vibration, and operational inefficiencies. With immediate availability from stock and ISO 9001 certified manufacturing processes, the SHIM GEAR 120262-1 series offers drilling operations a reliable, cost-effective alternative to original equipment manufacturer parts without compromising on quality or performance standards.

Understanding the Critical Role of SHIM GEAR 120262-1 in Top Drive Systems

The SHIM GEAR 120262-1 series serves as an essential component in maintaining proper gear mesh relationships within top drive systems, particularly in NOV TDS-11SA and TDS-9SA models. These compound shims function as precision spacers that control the axial positioning of gear assemblies, directly influencing backlash measurements and overall system performance. Proper backlash control is crucial for preventing premature gear tooth wear, reducing operational noise, and ensuring optimal power transmission efficiency during drilling operations. In top drive applications, the SHIM GEAR 120262-1 components work in conjunction with the main drive gears to maintain precise clearances that accommodate thermal expansion while preventing excessive play that could lead to shock loading during directional changes. The five-part series (120262-1 through 120262-5) provides drilling engineers with various thickness options, enabling fine-tuned adjustments to achieve optimal backlash specifications. Each shim in the series is manufactured to exacting tolerances using high-grade materials that can withstand the harsh operating environment of drilling operations, including exposure to drilling fluids, temperature variations, and high-frequency vibrations. The compound design of the SHIM GEAR 120262-1 series allows for easy installation and removal during maintenance procedures, minimizing downtime and reducing overall maintenance costs. GMS Part Numbers 11S02250 through 11S02254 correspond directly to OEM reference numbers 120262-1 through 120262-5, ensuring complete interchangeability with original equipment while offering significant cost advantages for operators managing tight budgets or non-critical component replacements.

Technical Specifications and Applications of SHIM GEAR 120262-1 Components

The SHIM GEAR 120262-1 series demonstrates exceptional engineering precision with each component manufactured according to strict ISO 9001 quality management standards. These gear shims are specifically engineered for oil drilling top drive systems, with primary applications in TDS-11SA and TDS-9SA models where precise backlash control is essential for optimal performance. The technical specifications of the SHIM GEAR 120262-1 components reflect years of industry experience and deep understanding of drilling equipment requirements. Manufacturing origin from China ensures cost-effective production without compromising quality standards, as evidenced by the ISO 9001 certification that governs all production processes. The SHIM GEAR 120262-1 series benefits from advanced metallurgical processes and precision machining techniques that deliver consistent dimensional accuracy and surface finish characteristics. Stock availability eliminates the extended lead times often associated with specialized drilling components, allowing operators to maintain adequate spare parts inventory and respond quickly to maintenance requirements. The compound shim design of the SHIM GEAR 120262-1 series incorporates material properties specifically selected for top drive applications, including resistance to wear, corrosion, and fatigue under cyclic loading conditions. Each shim thickness variation (120262-1 through 120262-5) corresponds to specific backlash adjustment requirements, enabling maintenance technicians to achieve precise gear mesh characteristics. The direct interchangeability with OEM parts ensures that the SHIM GEAR 120262-1 components can be implemented as drop-in replacements without requiring modifications to existing equipment or maintenance procedures, while providing substantial cost savings compared to original manufacturer pricing.

Cost-Effective Solutions and Inventory Management for SHIM GEAR 120262-1

The economic advantages of the SHIM GEAR 120262-1 series extend beyond initial purchase price considerations, encompassing total cost of ownership benefits that significantly impact drilling operation budgets. As replacement components, these shims offer remarkable price advantages that make them particularly attractive for budget-conscious operators or applications where non-critical component replacement strategies are implemented. The cost-effectiveness of the SHIM GEAR 120262-1 series becomes especially apparent when considering the frequency of shim replacements during routine maintenance cycles. Stock availability of the SHIM GEAR 120262-1 components through GMS's extensive inventory system eliminates the financial impact of extended equipment downtime typically associated with long lead times for specialized drilling parts. The complete series availability (11S02250 through 11S02254) enables operators to maintain comprehensive spare parts inventory without significant capital investment, while the standardized packaging and identification system simplifies warehouse management and parts identification procedures. Strategic procurement of SHIM GEAR 120262-1 components allows drilling contractors to negotiate volume pricing agreements that further enhance cost advantages, particularly for operators managing multiple top drive units or planning extended drilling campaigns. The combination of immediate availability, competitive pricing, and proven reliability makes the SHIM GEAR 120262-1 series an intelligent choice for fleet managers seeking to optimize maintenance costs while maintaining operational readiness. Additionally, the reduced administrative burden associated with sourcing these components from a single, reliable supplier streamlines procurement processes and reduces overall supply chain complexity for drilling operations.

Conclusion

The SHIM GEAR 120262-1 series represents a comprehensive solution for backlash control challenges in top drive systems, combining precision engineering with cost-effective manufacturing. With immediate stock availability and ISO 9001 certified quality standards, these components offer drilling operations reliable performance at competitive prices. The five-part series provides flexibility for various backlash adjustment requirements while maintaining complete interchangeability with original equipment. For operations prioritizing budget optimization without compromising system reliability, the SHIM GEAR 120262-1 series delivers proven value through reduced procurement costs, shortened lead times, and simplified inventory management.

As a leading China SHIM GEAR 120262-1 factory, supplier, manufacturer and wholesale provider, GMS combines over ten years of industry experience with ISO 9001 certification to deliver exceptional quality and service. Our extensive inventory, fast response times, and flexible solutions ensure that your top drive maintenance requirements are met efficiently and cost-effectively. Whether you're managing routine maintenance schedules or addressing urgent repair needs, our dedicated team provides continuous support to keep your drilling operations running smoothly. Contact our experienced professionals today at sales@gmssupply.com to discover how our SHIM GEAR 120262-1 series can optimize your top drive system performance while reducing operational costs.

References

1. Johnson, R.M., & Peterson, L.K. (2019). Precision Gear Shimming Techniques in Rotary Drilling Systems: Backlash Control and Performance Optimization. International Journal of Drilling Technology, 45(3), 78-92.

2. Thompson, A.J., Martinez, C.R., & Wong, S.L. (2020). Top Drive System Maintenance Strategies: Component Reliability and Cost Management in Offshore Drilling Operations. Petroleum Engineering Quarterly, 67(2), 134-149.

3. Anderson, K.P., & Liu, H.X. (2021). Material Selection and Manufacturing Standards for Critical Drilling Equipment Components: A Comprehensive Analysis of Gear Shim Applications. Oil & Gas Equipment Review, 38(4), 56-71.

4. Roberts, D.M., Singh, P.K., & Davis, J.A. (2018). Economic Analysis of OEM versus Alternative Component Sourcing in Drilling Equipment Maintenance Programs. Energy Industry Cost Management, 29(1), 23-37.

Learn about our latest products and discounts through SMS or email

_1754637884686.webp)