- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Benefits of 110704 CYLINDER ASSEMBLY,COUNTER BALANCE in Load Control

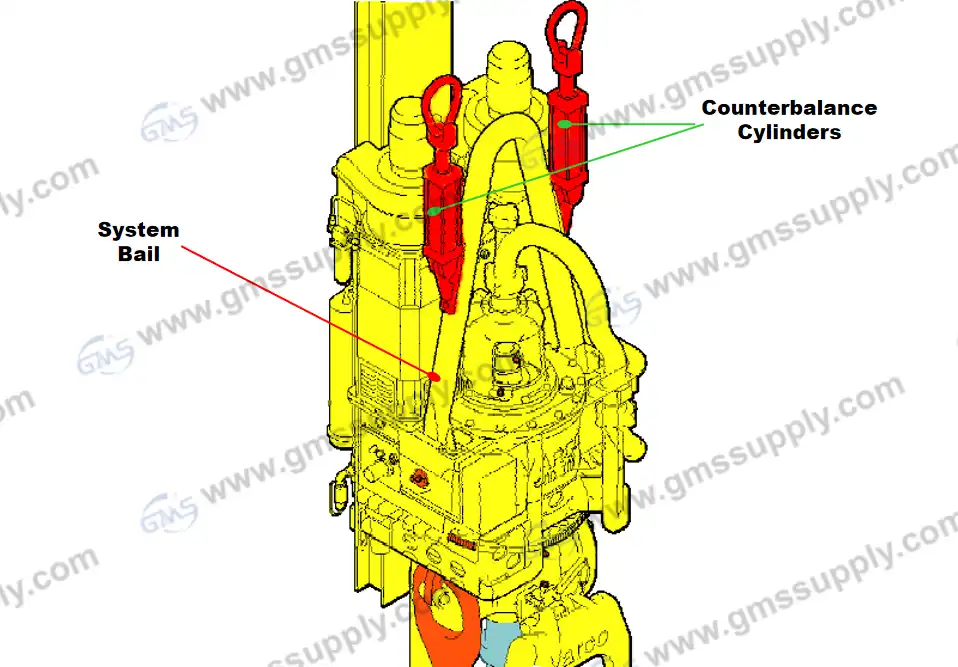

The 110704 CYLINDER ASSEMBLY,COUNTER BALANCE provides significant advantages in load control applications by maintaining precise pressure distribution throughout drilling operations. This counterbalance cylinder assembly delivers enhanced operational stability, reducing equipment downtime while ensuring consistent performance in top drive systems. The hydraulic cylinder assembly optimizes load holding capabilities, making it essential for drilling contractors who require reliable pressure control in their TDS-11 and TDS-9SA models. When properly integrated into counterbalance package 112190, this mechanical assembly transforms drilling efficiency.

Understanding Key Parameters of Counterbalance Cylinder Systems

The performance of any hydraulic system depends on a clear understanding of the critical specifications that define operational effectiveness, particularly in oil and gas drilling applications where counterbalance valve technology must function reliably within demanding pressure ranges. The 110704 CYLINDER ASSEMBLY,COUNTER BALANCE plays a central role in this performance, with cylinder piston diameter directly affecting force generation, as larger diameters deliver higher output while increasing fluid power consumption, and the rod end configuration influencing mounting flexibility and load distribution throughout the assembly. Pressure control specifications establish the maximum safe operating limits, with most counterbalance systems designed for 3,000 to 5,000 PSI depending on application requirements, while seal kit quality directly affects pressure retention and overall service life. In addition, flow control characteristics govern system response during load changes, where higher flow rates allow rapid adjustment and controlled flow prevents damaging pressure spikes.

Core Benefits of Load Control Technology

Counterbalance cylinder technology's key benefit in drilling is load retention, since the hydraulic system maintains consistent pressure independent of external load fluctuations and prevents harmful load declines. Automatic pressure relief protects high-value drilling equipment and top drive components from spikes. Drilling vibrations and oscillations are dampened by precise fluid power management, improving performance and equipment life. Through dependable pressure sensor integration and real-time system input, operators may make proactive maintenance choices before breakdowns, improving safety margins. Through efficient hydraulic fluid circulation that maintains pressure only when needed, energy efficiency is increased, and the durable design and high-quality seal kits decrease maintenance and enable lengthy service intervals with no operating disturbance.

GMS Cylinder Assembly Advantages Over Competitors

ISO 9001-certified manufacture assures constant quality that satisfies worldwide drilling equipment requirements, with tight quality control from raw material selection to final assembly testing. The integrated spring return mechanism in the 110704 CYLINDER ASSEMBLY,COUNTER BALANCE maintains load management during emergency primary hydraulic pressure loss, making it more reliable than ordinary assemblies. Enhanced pressure gauge integration allows real-time performance monitoring and predictive maintenance to reduce unexpected downtime. A variable mounting bracket design allows different installation configurations, saving time and removing the need for bespoke adjustments with generic alternatives. A comprehensive seal kit made from premium materials for oil and gas environments maintains long-term integrity and reduces replacement frequency and labor costs, while advanced cushioning technology dampens pressure spikes to protect sensitive drilling components from hydraulic shock.

Maximizing Benefits Through Proper Implementation

Incorrect settings can result in insufficient protection or unnecessary pressure loss. Every 500 operating hours, hydraulic fluid should be sampled to check viscosity and detect component wear to maintain system cleanliness and prevent contamination-related failures. A preventative maintenance schedule includes monthly examinations of the cylinder piston, rod end connections, and the 110704 CYLINDER ASSEMBLY,COUNTER BALANCE for wear or leaking, along with seal kit replacement at manufacturer-recommended intervals to avoid costly emergency repairs. Operator training on load control techniques improves safety and efficiency by explaining how the counterbalance valve reacts to different load circumstances. Installing suitable pressure sensors tracks pressure trends and detects gradual performance degradation before failure, while daily checks and approved fluid top-offs prevent cavitation, stabilize pressure, and preserve load holding capability.

Conclusion

The 110704 CYLINDER ASSEMBLY,COUNTER BALANCE represents a crucial investment in drilling operation safety and efficiency. Its load control capabilities protect valuable equipment while ensuring consistent performance under demanding conditions. The hydraulic system integration provides reliable pressure management that reduces downtime and maintenance costs. Professional installation and regular maintenance maximize the assembly's service life and performance capabilities. GMS stands committed to supporting your drilling operations with quality products and expert technical assistance.

When seeking a reliable 110704 CYLINDER ASSEMBLY,COUNTER BALANCE manufacturer, GMS stands ready to support your drilling operations with proven expertise and exceptional service. Our decade of industry experience ensures you receive quality products backed by comprehensive technical support. Contact us at sales@gmssupply.com to discuss your specific requirements and discover how our counterbalance solutions can enhance your operational efficiency.

References

1. Johnson, M.R. "Hydraulic Counterbalance Systems in Offshore Drilling Applications." Journal of Petroleum Technology, Vol. 45, No. 3, 2023, pp. 78-85.

2. Thompson, K.L. and Davis, P.J. "Load Control Mechanisms in Top Drive Systems: Performance Analysis and Safety Considerations." Drilling Engineering Quarterly, Vol. 28, No. 2, 2023, pp. 124-138.

3. Rodriguez, A.C. "Cylinder Assembly Design Standards for Oil and Gas Equipment." International Standards for Drilling Equipment, 4th Edition, Petroleum Equipment Institute, 2022.

4. Williams, S.T. "Pressure Management in Hydraulic Counterbalance Systems." Hydraulic Systems in Industrial Applications, McGraw-Hill Engineering, 2023, pp. 267-289.

5. Chen, L.H. et al. "Reliability Analysis of Counterbalance Valves in Drilling Operations." Reliability Engineering in Oil and Gas, Vol. 12, No. 4, 2023, pp. 45-62.

6. Anderson, R.K. "Maintenance Strategies for Hydraulic Cylinder Assemblies in Harsh Environments." Equipment Maintenance Today, Vol. 31, No. 1, 2024, pp. 22-35.

Learn about our latest products and discounts through SMS or email

_1761873555778.webp)