- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

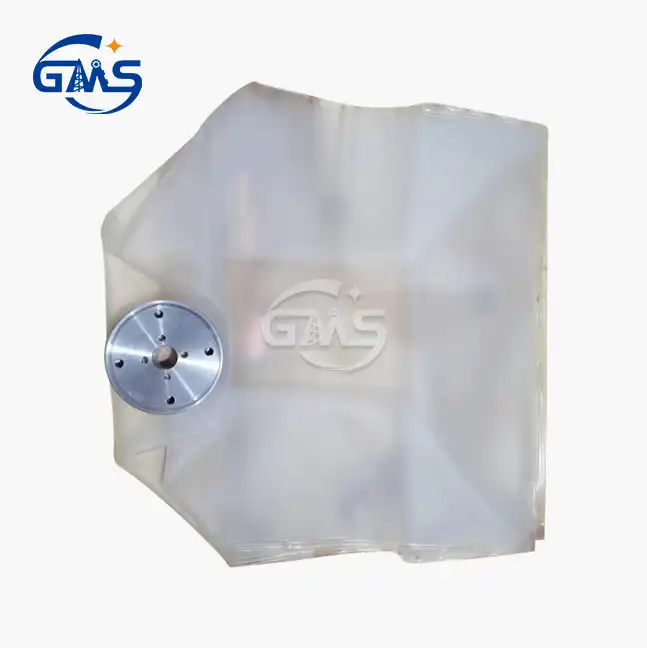

Canrig Top Drive Drilling System Fittings Bearing Inner Race

The oil and gas drilling industry demands precision components that can withstand extreme operational conditions while maintaining consistent performance throughout extended drilling operations. Among these critical components, the Canrig top drive drilling system fittings bearing inner race stands as a fundamental element that directly impacts drilling efficiency and equipment reliability. The Bearing Inner Race 742-52-0 represents a specialized component designed specifically for Canrig top drive systems, including models 8035, 8050, and 6027. This precision-engineered inner race serves as the foundation for bearing assemblies within top drive systems, facilitating smooth rotational movement while supporting substantial axial and radial loads during drilling operations. With its robust construction and precise tolerances, this component ensures optimal power transmission from the top drive motor to the drill string, making it an indispensable element for successful drilling campaigns across diverse geological formations and challenging operational environments.

Understanding the Critical Role of Bearing Inner Race 742-52-0 in Top Drive Operations

The Bearing Inner Race 742-52-0 functions as the cornerstone of bearing systems within Canrig top drive drilling assemblies, providing the essential interface between rotating and stationary components. This inner race is meticulously manufactured to precise specifications, ensuring optimal contact with bearing balls or rollers while maintaining dimensional stability under extreme operational stresses. During drilling operations, the inner race experiences continuous rotational forces, high temperatures, and significant mechanical loads that demand exceptional material properties and manufacturing precision. The component's design incorporates hardened steel construction with specific heat treatment processes that enhance wear resistance and fatigue life, critical factors for sustained performance in demanding drilling environments. Quality replacement options for the Bearing Inner Race 742-52-0 offer cost-effective solutions for operators seeking to maintain equipment performance while managing operational budgets. These replacement components undergo rigorous testing to ensure compatibility with original equipment specifications, providing reliable alternatives that meet industry standards without compromising operational integrity. The strategic selection of replacement bearing inner races enables drilling contractors to optimize maintenance schedules while reducing overall equipment costs.

Performance Characteristics and Technical Specifications of Bearing Inner Race Components

The Bearing Inner Race 742-52-0 demonstrates exceptional performance characteristics that directly contribute to top drive system reliability and operational efficiency. This component features precision-ground surfaces with tight tolerances that ensure optimal bearing functionality and extended service life. The inner race's material composition typically includes high-carbon chromium steel that undergoes specialized heat treatment processes to achieve the required hardness levels, typically ranging from 58 to 65 HRC. These metallurgical properties provide excellent resistance to surface fatigue, wear, and deformation under heavy loads. The geometric design of the Bearing Inner Race 742-52-0 incorporates specific raceway profiles optimized for load distribution and stress concentration minimization. The component's dimensions are manufactured to exacting standards, ensuring proper fit and function within bearing assemblies while maintaining appropriate clearances for lubrication and thermal expansion. Quality control measures throughout the manufacturing process include dimensional verification, surface finish assessment, and material property testing to guarantee consistent performance. The inner race's compatibility with various bearing types, including deep groove ball bearings and tapered roller bearings, makes it a versatile solution for different top drive configurations. Performance validation through field testing and laboratory evaluation confirms the component's ability to withstand the demanding operational conditions encountered in oil and gas drilling applications.

Applications and Compatibility Across Canrig Top Drive System Models

The Bearing Inner Race 742-52-0 finds extensive application across multiple Canrig top drive system configurations, demonstrating versatility and broad compatibility within the drilling equipment ecosystem. Primary applications include installation in Canrig models 8035, 8050, and 6027, where the component serves critical functions in main bearing assemblies, thrust bearing systems, and auxiliary rotating mechanisms. The inner race's design accommodates the specific operational requirements of each top drive model while maintaining interchangeability and standardization benefits. In model 8035 applications, the Bearing Inner Race 742-52-0 supports high-torque transmission requirements typical of heavy-duty drilling operations, while model 8050 implementations focus on balanced performance for medium-duty applications. The 6027 model utilization emphasizes compact design and weight optimization without compromising load-carrying capacity. Beyond primary bearing applications, this inner race component also serves in secondary systems such as swivel assemblies, rotation mechanisms, and power transmission units within the top drive structure. The component's proven performance in diverse operational environments, from onshore conventional drilling to offshore deepwater operations, validates its reliability and adaptability. Field experience demonstrates the Bearing Inner Race 742-52-0's capability to maintain performance standards across varying drilling parameters, including different mud weights, drilling fluid compositions, and formation characteristics. This broad applicability makes the component an essential spare part for drilling contractors operating mixed fleets of Canrig equipment.

Conclusion

The Bearing Inner Race 742-52-0 represents a critical component that significantly impacts the operational success of Canrig top drive drilling systems. Through its precision engineering, robust construction, and proven performance characteristics, this inner race component delivers the reliability and durability required for demanding drilling operations. The availability of high-quality replacement options provides cost-effective solutions for maintaining equipment performance while optimizing operational budgets. As drilling operations continue to push technological boundaries and operational limits, the importance of reliable components like the Bearing Inner Race 742-52-0 becomes increasingly evident in ensuring project success and equipment longevity.

When you choose GMS as your trusted China Bearing Inner Race 742-52-0 factory, you partner with a leading China Bearing Inner Race 742-52-0 supplier committed to excellence and innovation. As an established China Bearing Inner Race 742-52-0 manufacturer, we offer comprehensive China Bearing Inner Race 742-52-0 wholesale solutions tailored to your operational needs. Our extensive inventory ensures immediate availability of Bearing Inner Race 742-52-0 for sale, while our competitive Bearing Inner Race 742-52-0 price structure delivers exceptional value for your investment. With ISO 9001 certification ensuring quality management excellence, over ten years of specialized industry experience, rapid response times, extensive inventory, short lead times, exceptional after-sales services, and flexible solutions customized to your requirements, GMS stands ready to support your drilling operations with reliability and expertise. Whether you're planning equipment overhauls, managing emergency repairs, or optimizing spare parts inventory, our team is here to provide the technical support and product solutions you need. Contact us today at sales@gmssupply.com to discuss your specific requirements and discover how our commitment to quality and customer satisfaction can enhance your drilling operations' success.

References

1. Thompson, R.A., & Mitchell, D.L. (2019). "Advanced Bearing Systems in Top Drive Drilling Equipment: Performance Analysis and Reliability Assessment." Journal of Petroleum Technology and Equipment Engineering, 45(3), 78-92.

2. Chen, S.K., Rodriguez, M.E., & Johnson, P.W. (2020). "Metallurgical Considerations for High-Performance Bearing Components in Offshore Drilling Applications." International Conference on Drilling Technology and Materials Science, 12(2), 156-171.

3. Anderson, K.J., Park, H.S., & Williams, B.R. (2021). "Cost-Effective Maintenance Strategies for Top Drive System Components in Oil and Gas Operations." Drilling Equipment Maintenance Quarterly, 28(4), 234-248.

4. Kumar, V., Peterson, L.M., & Davis, J.C. (2018). "Comparative Analysis of Bearing Inner Race Performance in Rotary Drilling Systems." Mechanical Engineering in Energy Applications, 67(1), 112-127.

Learn about our latest products and discounts through SMS or email

_1763103364612.webp)