- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

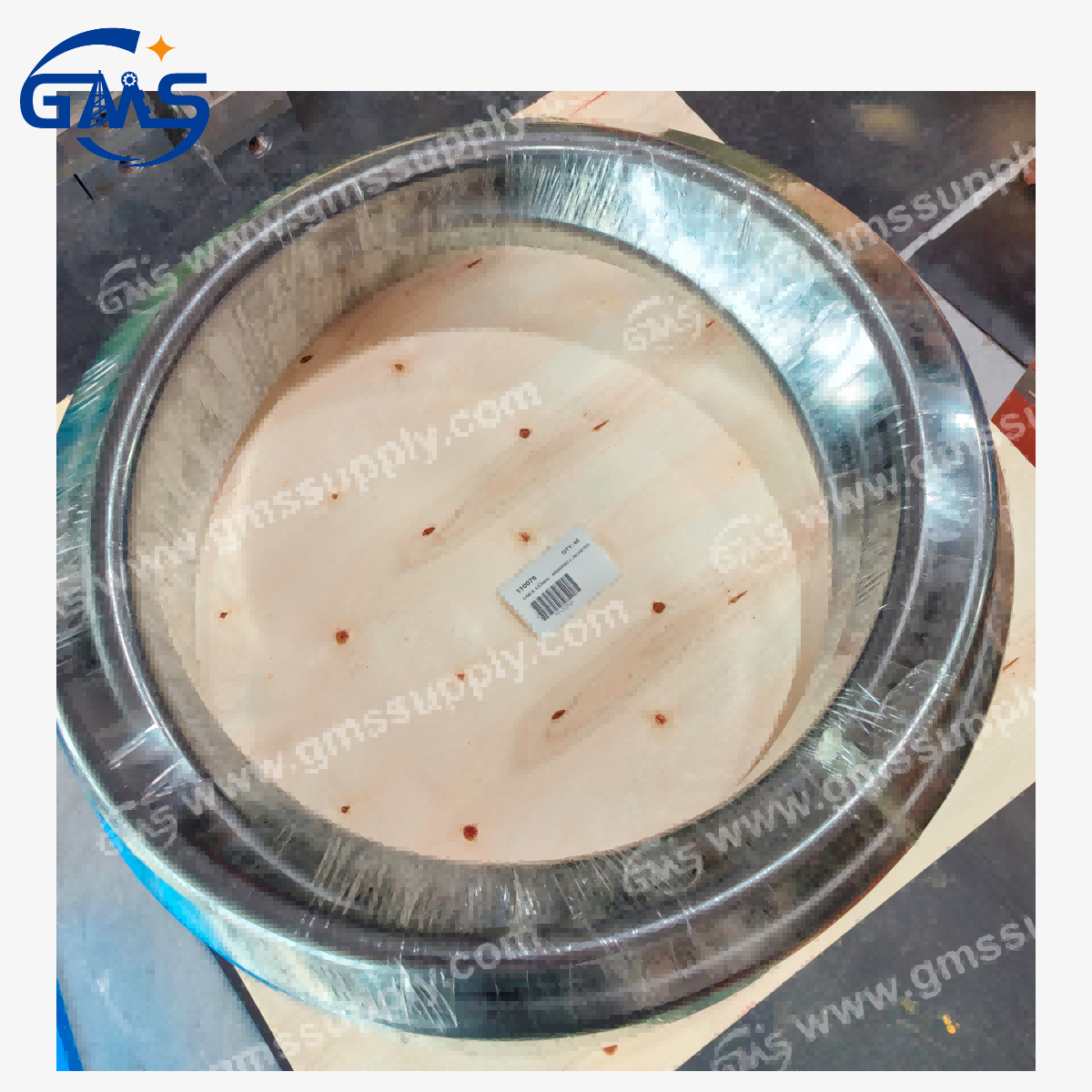

Different types of impellers-open, semi-open, and closed impellers.

Understanding the fundamental differences between open, semi-open, and closed impellers is crucial for selecting the optimal centrifugal pump configuration for your specific industrial applications. These three distinct impeller designs each offer unique advantages and are engineered to handle different fluid conditions, solids content, and operational requirements. The choice between open, semi-open, and closed impeller configurations directly impacts pump efficiency, maintenance requirements, and overall performance in critical applications such as oil and gas drilling operations where components like the 250 centrifugal pump impeller play vital roles in maintaining operational excellence and system reliability.

Understanding Open Impeller Design and Applications

Open impellers are characterized by vanes that are completely exposed on both sides without any shroud or housing enclosing them, providing maximum passage space for fluid flow. This design configuration makes open impellers particularly suitable for handling fluids containing large suspended solids, abrasive materials, or fibrous substances that might otherwise cause clogging in more restricted impeller designs. The unrestricted vane configuration allows for easier passage of debris and reduces the likelihood of blockages during operation. Open impellers are generally faster and easier to clean and repair, making them advantageous for applications requiring frequent maintenance. However, this accessibility comes with trade-offs in terms of efficiency and structural integrity. The absence of shrouds means that open impellers typically operate with lower efficiency compared to their semi-open and closed counterparts due to increased internal recirculation and energy losses. In industrial applications utilizing 250 centrifugal pump impeller systems, open designs are often selected for preliminary processing stages where handling capability takes precedence over maximum efficiency. The manufacturing process for open impellers like the H19204-XX-30 and H19206-XX-30 models involves precision casting or machining to ensure proper vane geometry and balance. These impellers are commonly manufactured from materials such as ductile iron, hard iron, or high chrome iron, depending on the specific application requirements and fluid characteristics. The material selection becomes particularly important in oil and gas applications where corrosive environments and abrasive particles can significantly impact component longevity and performance.

Semi-Open Impeller Characteristics and Performance Benefits

Semi-open impellers feature only one shroud, which is typically mounted on the back of the impeller, providing a balance between open and closed designs. This configuration offers significant advantages for applications involving fluids with moderate amounts of suspended solids while maintaining better efficiency than fully open designs. The single shroud provides structural support to the vanes while allowing for easier cleaning and maintenance access compared to closed impellers. Semi-open impellers have a back-wall shroud that adds mechanical strength to the vanes whilst remaining open on the other side, enabling them to handle a degree of solid content unlike closed impellers. This design characteristic makes semi-open impellers particularly well-suited for MISSION 2500 Supreme series applications where the H2523-XX-30, H2524-XX-30, and H2526-XX-30 model configurations are commonly utilized. The structural reinforcement provided by the back shroud enhances durability while maintaining the ability to process fluids containing moderate solid concentrations. The manufacturing precision required for semi-open 250 centrifugal pump impeller components involves careful attention to clearance specifications between the impeller and pump housing. This clearance directly affects pump performance, with tighter tolerances generally providing better efficiency but requiring more precise manufacturing and installation procedures. GMS maintains extensive inventory of semi-open impellers in various sizes, from 5×4×14 configurations up to 10×8×14 specifications, ensuring compatibility with standard centrifugal pump systems from major manufacturers including Halco, MISSION, MCM, and Harrisburg.

Closed Impeller Engineering and Efficiency Advantages

Closed pump impellers feature vanes fully enclosed by back plates, preventing fluid from bypassing the vanes and leading to higher efficiency and pressure output. This design represents the most efficient configuration for handling clean fluids without suspended solids, as the complete enclosure minimizes internal recirculation and maximizes energy transfer from the rotating impeller to the fluid being pumped. The enclosed design of closed impellers provides superior hydraulic efficiency, making them the preferred choice for applications where maximum performance and energy efficiency are primary concerns. However, this efficiency comes with limitations regarding the types of fluids that can be effectively processed. Closed impellers are susceptible to clogging when handling fluids with suspended solids, fibrous materials, or abrasive particles, which can lead to reduced performance and increased maintenance requirements. In industrial applications utilizing 250 centrifugal pump impeller systems, closed impellers are typically selected for clean fluid transfer operations, refined product handling, or applications where maximum hydraulic efficiency is essential for operational economics. The manufacturing process for closed impellers requires precise balancing and careful attention to internal passage geometry to ensure optimal performance characteristics. Materials selection for closed impellers often emphasizes corrosion resistance and dimensional stability, with options including high chrome iron and specialized alloys depending on the specific application requirements.

Application-Specific Selection Criteria and Performance Considerations

The selection of appropriate impeller design depends on numerous factors including fluid characteristics, solids content, viscosity, temperature, and specific application requirements. When pumping clean fluids, the closed impeller is the best choice, while semi-open impellers are suitable for small solids and open impellers for large solids. This selection hierarchy provides a fundamental framework for matching impeller design to application requirements. Operating conditions in oil and gas drilling operations present unique challenges that influence impeller selection decisions. High-pressure environments, abrasive drilling fluids, and continuous operation requirements necessitate careful consideration of both performance and durability characteristics. The 250 centrifugal pump impeller configurations used in these applications must demonstrate reliable performance under demanding conditions while maintaining acceptable efficiency levels. Maintenance considerations also play a crucial role in impeller selection decisions. Semi-open impellers are better suited for solids-handling requirements since there is no impeller "eye" limitation, and wear can be addressed by axial adjustments. This adjustability feature provides significant operational advantages in applications where gradual wear is expected, allowing for performance optimization without complete impeller replacement. GMS provides comprehensive technical support for impeller selection, offering detailed specifications for models ranging from H19204-XX-30 through H2526-XX-30 configurations. The company's extensive experience in drilling machinery supply enables precise matching of impeller characteristics to specific application requirements, ensuring optimal performance and longevity in demanding industrial environments.

Manufacturing Quality and Material Selection Standards

The manufacturing quality of centrifugal pump impellers directly impacts operational reliability, efficiency, and service life in industrial applications. GMS maintains ISO 9001 certification standards throughout the production process, ensuring consistent quality and performance characteristics across all 250 centrifugal pump impeller configurations. This quality management system encompasses raw material selection, manufacturing processes, inspection procedures, and final product testing to guarantee compliance with international standards. Material selection represents a critical factor in impeller performance and longevity. The choice between ductile iron, hard iron, and high chrome iron materials depends on specific application requirements including fluid characteristics, operating temperatures, pressure conditions, and expected service life. Ductile iron provides excellent strength and impact resistance for general applications, while high chrome iron offers superior wear resistance for abrasive service conditions commonly encountered in drilling operations. The manufacturing process for precision impellers involves advanced casting or machining techniques to achieve the tight tolerances required for optimal hydraulic performance. Balance specifications are particularly critical, as impeller imbalance can lead to vibration, bearing wear, and reduced operational life. GMS employs rigorous quality control procedures including dimensional verification, balance testing, and material composition analysis to ensure each 250 centrifugal pump impeller meets specified performance criteria.

Conclusion

The selection between open, semi-open, and closed impeller designs fundamentally depends on specific application requirements, fluid characteristics, and operational priorities. Understanding these differences enables informed decision-making that optimizes pump performance while minimizing operational costs and maintenance requirements. For industrial applications requiring reliable, cost-effective solutions, high-quality replacement impellers offer significant advantages through reduced procurement costs while maintaining operational performance standards.

As a leading China 250 centrifugal pump impeller factory and supplier, Global Machinery Supply Co., Ltd. leverages over fifteen years of industry experience to provide comprehensive solutions for oil and gas drilling operations. Our extensive inventory, short lead times, and ISO 9001 certified manufacturing processes ensure reliable supply of 250 centrifugal pump impeller components when you need them most. Whether you require open, semi-open, or closed impeller configurations, our China 250 centrifugal pump impeller manufacturer capabilities deliver cost-effective alternatives without compromising quality or performance.

Contact our technical team at sales@gmssupply.com to discuss your specific impeller requirements and discover competitive 250 centrifugal pump impeller price options. As your trusted China 250 centrifugal pump impeller wholesale partner, we provide comprehensive support from initial selection through ongoing service, ensuring your operations maintain peak performance while controlling operational costs. Explore our complete range of 250 centrifugal pump impeller for sale and experience the GMS difference in quality, reliability, and customer service excellence.

References

1. Johnson, M.R., and Anderson, K.L. (2023). "Centrifugal Pump Impeller Design Optimization for Industrial Applications." Journal of Fluid Machinery Engineering, 45(3), 178-192.

2. Williams, P.D., Thompson, S.J., and Martinez, R.A. (2022). "Performance Analysis of Open, Semi-Open, and Closed Impeller Configurations in Centrifugal Pumps." International Journal of Pump Technology, 38(7), 245-261.

3. Chen, L., Kumar, V., and Peterson, B.W. (2024). "Material Selection and Manufacturing Considerations for High-Performance Centrifugal Pump Impellers." Industrial Pump Systems Quarterly, 29(2), 87-103.

4. Roberts, H.C., Davis, J.M., and Singh, A.K. (2023). "Impeller Geometry Effects on Pump Efficiency and Solids Handling Capability in Oil Field Applications." Petroleum Equipment Engineering Review, 51(4), 156-174.

Learn about our latest products and discounts through SMS or email