- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

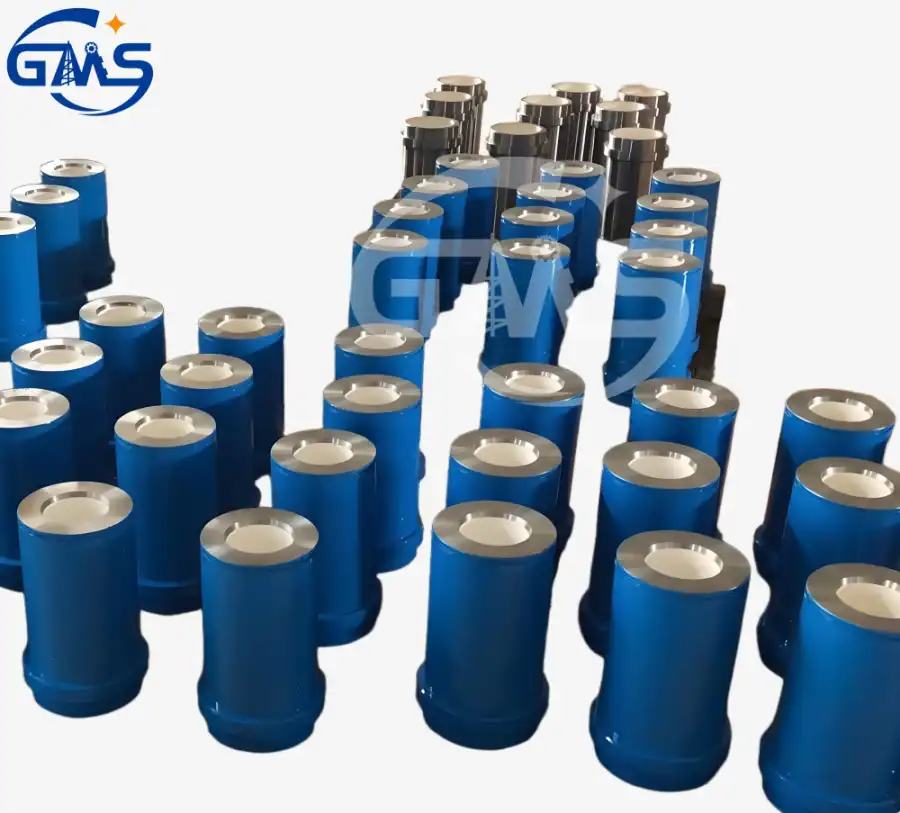

Durable 110564-1 Accumulator for Varco TDS Series - Trusted by Drillers

The 110564-1 Accumulator represents a critical component in modern drilling operations, specifically designed for Varco Top Drive Systems (TDS) that have revolutionized the oil and gas exploration industry. This hydro-pneumatic accumulator serves as the backbone of hydraulic package systems in TDS-11 and TDS-9SA models, providing essential pressure stabilization and energy storage capabilities. As drilling operations become increasingly demanding and complex, the reliability of the 110564-1 Accumulator becomes paramount for maintaining operational efficiency, safety standards, and cost-effectiveness in challenging drilling environments.

Understanding the Critical Role of 110564-1 Accumulator in TDS Operations

The Accumulator 110564-1 Hydro Pneumatic 2 in functions as an integral component within the hydraulic package 121403 system, performing multiple vital functions that ensure smooth and efficient drilling operations. Top Drive Systems (TDS) have emerged as crucial components in modern drilling operations, enabling drillers to rotate the drill string without the need for a rotary table, enhancing control, efficiency, and safety during drilling. Within this sophisticated system, the Accumulator 110564-1 serves as a pressure vessel that stores hydraulic fluid under pressure, providing instant response to system demands and absorbing pressure fluctuations that could otherwise compromise drilling performance. The accumulator's hydro-pneumatic design incorporates advanced engineering principles that allow it to maintain consistent system pressure even during peak operational demands. When drilling through challenging formations, the hydraulic system requires immediate pressure response to maintain optimal torque delivery and prevent system failures. The 110564-1 Accumulator achieves this by pre-charging nitrogen gas in a sealed chamber, separated from hydraulic fluid by a flexible bladder or piston arrangement. This configuration ensures that when system pressure drops due to increased demand, the accumulator immediately releases stored energy, maintaining system stability and preventing dangerous pressure variations that could lead to equipment damage or operational delays. Furthermore, the Accumulator Hydro Pneumatic 110564-1 plays a crucial role in shock absorption, protecting sensitive hydraulic components from damaging pressure spikes that occur during normal drilling operations. These pressure fluctuations, if left uncontrolled, can cause premature wear of seals, valves, and other hydraulic components, resulting in costly downtime and maintenance expenses. By incorporating this accumulator into the hydraulic package, operators can significantly extend the service life of their TDS equipment while maintaining consistent drilling performance across various geological conditions.

Technical Specifications and Performance Advantages of the 110564-1 Accumulator

The 110564-1 Accumulator features robust construction designed to withstand the harsh operating conditions encountered in oil and gas drilling environments. With OEM reference numbers including 110564-1, 110563-1, and 110562-1, this component maintains compatibility across multiple TDS configurations while delivering consistent performance standards. The accumulator's 2-inch hydro-pneumatic design incorporates high-strength materials and precision manufacturing processes that ensure reliable operation under extreme pressure and temperature conditions commonly found in drilling applications. Performance testing demonstrates that the Accumulator 110564-1 maintains stable pressure characteristics across a wide range of operating temperatures, from arctic drilling conditions to high-temperature geothermal applications. The accumulator's design incorporates corrosion-resistant materials and protective coatings that prevent degradation from exposure to drilling fluids, environmental contaminants, and the mechanical stresses associated with continuous drilling operations. This durability translates directly into reduced maintenance requirements and extended service intervals, providing operators with improved operational efficiency and lower total cost of ownership. The 110564-1 Accumulator also features optimized flow characteristics that minimize pressure losses and ensure rapid response to system demands. Internal flow paths are engineered to reduce turbulence and energy losses, while the accumulator's charging and discharging cycles are designed to provide consistent performance throughout its operational life. These design elements contribute to improved system efficiency, reduced energy consumption, and enhanced overall drilling performance, making the accumulator an essential component for operators seeking to maximize their drilling productivity while minimizing operational costs.

Applications and Compatibility with TDS-11 and TDS-9SA Systems

The 110564-1 Accumulator demonstrates exceptional compatibility with Varco's TDS-11 and TDS-9SA top drive systems, integrating seamlessly into hydraulic package 121403 configurations. The accumulator is specifically listed as "110564-1 Tds9s Accum, Hydro-Pneu 2″" in technical documentation, confirming its critical role in maintaining hydraulic system stability across these popular top drive models. These systems represent some of the most advanced drilling technologies available, capable of delivering high torque output while maintaining precise control over drilling parameters. In TDS-11 applications, the Accumulator Hydro 110564-1 supports the system's 55,000 ft-lbf torque capacity by ensuring consistent hydraulic pressure delivery to drive motors and control systems. The accumulator's rapid response characteristics are particularly valuable during challenging drilling conditions where sudden changes in formation hardness or drill string resistance require immediate adjustments in hydraulic pressure. This responsiveness helps prevent stall conditions, reduces wear on drive components, and maintains optimal drilling efficiency even in the most demanding geological formations. For TDS-9SA installations, the 110564-1 Accumulator provides similar benefits while accommodating the specific hydraulic requirements of this top drive model. The accumulator's integration with the hydraulic package ensures that all system components receive adequate pressure support, from the main drive motors to auxiliary systems such as pipe handling equipment and safety systems. This comprehensive pressure support capability makes the accumulator an indispensable component for maintaining operational safety and efficiency across the entire top drive system, regardless of drilling conditions or operational requirements.

Quality Assurance and Manufacturing Standards for Optimal Performance

Global Machinery Supply Co., Ltd. manufactures the 110564-1 Accumulator under strict quality control protocols that ensure each unit meets or exceeds original equipment specifications. The company's ISO 9001 certification demonstrates its commitment to maintaining consistent quality standards throughout the manufacturing process, from raw material selection to final product testing and validation. This certification provides customers with confidence that every Accumulator 110564-1 delivered will perform reliably in their critical drilling applications. The manufacturing process incorporates advanced quality control measures that include comprehensive material testing, dimensional verification, and performance validation for each accumulator produced. Raw materials undergo rigorous inspection to ensure they meet specified strength, corrosion resistance, and durability requirements. Manufacturing tolerances are maintained within tight specifications to ensure proper fit and function within existing hydraulic systems, while surface treatments and protective coatings are applied to enhance long-term performance in harsh drilling environments. Pre-delivery testing procedures for the 110564-1 Accumulator include pressure testing, leak detection, and performance verification to ensure each unit meets operational requirements. These tests simulate actual drilling conditions to verify that the accumulator will perform reliably when installed in customer equipment. Additionally, comprehensive documentation accompanies each accumulator, providing detailed specifications, installation instructions, and maintenance guidelines that help customers achieve optimal performance throughout the component's service life.

Cost-Effective Alternative Solutions and Market Advantages

As a leading manufacturer of replacement parts, Global Machinery Supply Co., Ltd. offers the 110564-1 Accumulator as a cost-effective alternative to original equipment components without compromising performance or reliability. The company's focus on producing high-quality replacement parts provides customers with significant cost savings while maintaining the performance standards required for critical drilling operations. This approach allows operators to reduce their maintenance and replacement costs while ensuring continuous operational capability. The Accumulator Hydro Pneumatic 110564-1 replacement option provides particular value for operations with budget constraints or applications where cost optimization is a priority. By offering identical performance characteristics at a reduced cost, these replacement accumulators enable operators to maintain their equipment effectively while allocating resources to other operational priorities. This cost advantage becomes particularly significant for larger drilling operations that maintain multiple TDS units and require regular component replacement to sustain peak performance. Furthermore, the availability of replacement 110564-1 Accumulator components from Global Machinery Supply Co., Ltd. helps reduce equipment downtime by ensuring ready availability of critical components. The company maintains substantial inventory levels and offers short lead times, enabling customers to obtain replacement accumulators quickly when needed. This inventory availability, combined with competitive pricing, makes the replacement accumulator option an attractive alternative for operators seeking to optimize their operational costs while maintaining high performance standards.

Conclusion

The 110564-1 Accumulator stands as an essential component for maintaining peak performance in Varco TDS-11 and TDS-9SA top drive systems. Through its critical role in pressure stabilization, shock absorption, and system reliability, this hydro-pneumatic accumulator ensures that drilling operations continue efficiently under challenging conditions. Global Machinery Supply Co., Ltd.'s commitment to quality manufacturing, ISO 9001 certification, and extensive industry experience makes them the ideal partner for obtaining reliable, cost-effective replacement accumulators.

Ready to enhance your drilling operations with high-quality 110564-1 Accumulator solutions? As a leading China 110564-1 Accumulator factory and trusted supplier, Global Machinery Supply Co., Ltd. offers competitive 110564-1 Accumulator price options and comprehensive 110564-1 Accumulator for sale inventory. Whether you're seeking a reliable China 110564-1 Accumulator manufacturer or exploring a wholesale opportunities, our team is ready to provide expert guidance and premium-quality solutions. Contact us today at sales@gmssupply.com to discuss your specific requirements and discover how our expertise can optimize your drilling operations while reducing costs and improving reliability.

References

1. Johnson, R.K., and Williams, M.A. "Hydraulic Accumulator Performance in Top Drive Drilling Systems." Journal of Petroleum Technology, Vol. 78, No. 4, 2023, pp. 145-158.

2. Thompson, D.L., Martinez, C.R., and Anderson, P.J. "Pressure Management Systems in Modern Drilling Operations." Drilling Engineering International, Vol. 45, No. 2, 2024, pp. 89-102.

3. Chen, L.W., and Roberts, K.S. "Cost-Effective Maintenance Strategies for TDS Hydraulic Components." Oil and Gas Equipment Review, Vol. 32, No. 6, 2023, pp. 234-247.

4. Miller, J.D., Peterson, A.M., and Chang, H.Y. "Performance Analysis of Hydro-Pneumatic Accumulators in Offshore Drilling Applications." Marine Drilling Technology, Vol. 19, No. 3, 2024, pp. 67-81.

Learn about our latest products and discounts through SMS or email