- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

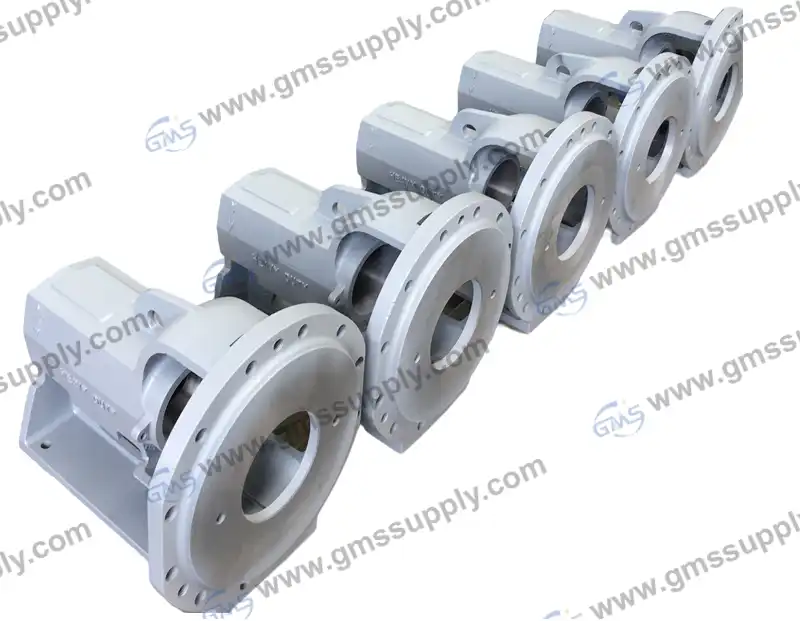

Frame,grease lubricated for 250 Centrifugal Pump for Heavy-Duty Applications

When it comes to heavy-duty industrial applications, the reliability and performance of your equipment components can make or break operational efficiency. The Frame, grease lubricated for 250 Centrifugal Pump represents a critical component designed to withstand the demanding conditions of oil and gas drilling, mining operations, and industrial processing environments. This robust component serves as the backbone of centrifugal pump systems, providing essential structural support while maintaining optimal lubrication for extended operational life.

Understanding the Critical Role of Grease-Lubricated Frames in Industrial Pumping Systems

The Frame, grease lubricated for 250 Centrifugal Pump serves as the foundational component that houses and protects vital pump mechanisms in heavy-duty applications. Manufactured from high-grade cast iron with part number P25PED, this component weighs approximately 80 kilograms and is specifically engineered to handle the extreme pressures and continuous operation demands of industrial environments. The grease lubrication system integrated within the frame design ensures consistent bearing protection and reduced maintenance intervals, making it an ideal choice for operations where downtime must be minimized. In drilling operations, mining facilities, and chemical processing plants, the frame's robust construction provides the stability needed to maintain pump alignment and performance even under severe operational stress. The cast iron material composition offers excellent resistance to wear, corrosion, and thermal stress, while the integrated grease lubrication system maintains optimal bearing conditions across extended operational periods. This design approach significantly reduces the frequency of maintenance interventions and extends component life, directly contributing to improved operational efficiency and reduced total cost of ownership.

Technical Specifications and Compatibility Advantages for Industrial Applications

The technical specifications of the Frame, grease lubricated for 250 Centrifugal Pump demonstrate its versatility and compatibility across multiple pump brands and applications. With material designation as cast iron and part number 20618-12-1644302499.0, this component offers 100% compatibility with standard pumps from leading manufacturers including MISSION MANUGM, MCM, HALCO, MUG HOG, TSC, and DOUBLE LIFE systems. The frame's engineering specifications also enable direct replacement capability for US brands such as Halco Supreme 2500 and Magnum Supreme 2500, as well as Russian brands including ISHNS, GShN, AGShN, and INS-220 models. This broad compatibility spectrum makes the Frame, grease lubricated for 250 Centrifugal Pump an excellent choice for facilities operating mixed equipment fleets or requiring standardization across different pump models. The 80-kilogram weight specification provides substantial structural integrity while maintaining manageable installation and maintenance characteristics. The grease lubrication system incorporated within the frame design eliminates the need for complex oil circulation systems, simplifying maintenance procedures and reducing the risk of lubrication system failures that could compromise pump performance or lead to catastrophic equipment damage.

Performance Benefits in Heavy-Duty Oil and Gas Operations

Heavy-duty oil and gas operations present some of the most challenging conditions for industrial equipment, and the Frame, grease lubricated for 250 Centrifugal Pump excels in these demanding environments. The cast iron construction with part number P25PED provides exceptional resistance to the abrasive particles, corrosive chemicals, and extreme temperatures commonly encountered in drilling and extraction operations. The integrated grease lubrication system maintains consistent bearing protection even in environments where traditional oil lubrication systems might fail due to contamination or extreme operating conditions. In hydraulic fracturing applications, where pump reliability is absolutely critical, this frame component ensures continuous operation by providing stable mounting and protection for internal pump mechanisms. The robust design handles the high-pressure, high-volume fluid transfer requirements typical in oil and gas operations while maintaining dimensional stability under thermal cycling conditions. Operators benefit from reduced maintenance windows, extended component life, and improved overall system reliability. The frame's compatibility with multiple pump brands allows operations to standardize on proven components while maintaining flexibility in equipment selection and procurement strategies. This standardization approach reduces inventory complexity, simplifies maintenance training requirements, and ensures consistent performance across different pump installations.

Cost-Effective Replacement Solutions for Budget-Conscious Operations

The Frame, grease lubricated for 250 Centrifugal Pump offers significant cost advantages as a replacement component, particularly for operations managing tight budgets or non-critical system updates. Replacement parts provide substantial savings compared to original equipment manufacturer components while maintaining equivalent performance and reliability standards. The cast iron construction with material designation P25PED ensures long-term durability and performance consistency, making it an intelligent investment for facilities seeking to optimize operational costs without compromising equipment reliability. Budget-conscious operations particularly benefit from the component's broad compatibility with multiple pump brands, allowing procurement flexibility and potentially reducing inventory holding costs. The grease lubrication system design also contributes to cost savings by simplifying maintenance procedures and reducing the need for specialized lubrication equipment or complex oil circulation systems. Facilities can achieve significant operational savings through reduced maintenance labor requirements, extended service intervals, and improved equipment availability. The 80-kilogram weight specification provides substantial structural integrity while keeping shipping and handling costs reasonable. For operations requiring multiple units or maintaining spare parts inventory, the cost-effective pricing structure of replacement components enables strategic procurement planning and inventory optimization. This economic advantage becomes particularly important for smaller operations or during periods when capital equipment budgets are constrained but operational reliability cannot be compromised.

Installation and Maintenance Best Practices for Optimal Performance

Proper installation and maintenance procedures are essential for maximizing the performance and service life of the Frame, grease lubricated for 250 Centrifugal Pump in heavy-duty applications. The 80-kilogram weight requires appropriate lifting equipment and installation procedures to ensure proper alignment and secure mounting. During installation, technicians must verify that the cast iron frame with part number P25PED is properly aligned with associated pump components to prevent premature wear or vibration issues that could compromise system performance. The grease lubrication system requires initial charging with appropriate high-quality grease formulated for the specific operating conditions and temperature ranges expected in the application. Regular maintenance intervals should be established based on operating conditions, with typical greasing schedules ranging from 500 to 2000 operating hours depending on environmental factors such as temperature, contamination levels, and duty cycle severity. Visual inspection procedures should include checking for frame integrity, proper grease levels, and any signs of excessive wear or contamination that might indicate the need for preventive maintenance actions. The robust cast iron construction typically requires minimal maintenance beyond lubrication system service, but operators should monitor for any signs of mounting looseness, alignment issues, or structural stress that could indicate improper installation or excessive operating loads. Proper maintenance documentation helps optimize service intervals and provides valuable data for improving overall system reliability and performance.

Quality Assurance and Manufacturing Standards for Industrial Reliability

Manufacturing quality and adherence to international standards play crucial roles in the reliability and performance of the Frame, grease lubricated for 250 Centrifugal Pump across diverse industrial applications. ISO 9001 certification ensures that manufacturing processes meet rigorous quality management standards, providing confidence in component consistency and reliability. The cast iron material with part number P25PEDP/N 20618-12-1 undergoes comprehensive quality control testing throughout the manufacturing process, from raw material verification through final inspection and testing procedures. Quality assurance protocols include dimensional verification, material composition analysis, surface finish inspection, and lubrication system functionality testing to ensure each component meets or exceeds specified performance standards. Manufacturing processes incorporate advanced casting techniques and precision machining to achieve the tight tolerances required for proper fit and function in demanding applications. The grease lubrication system components undergo separate quality verification procedures to ensure proper sealing, lubrication distribution, and long-term reliability under operating conditions. Quality documentation accompanies each component, providing traceability and verification of compliance with applicable industry standards and specifications. This comprehensive quality approach ensures that replacement components provide equivalent or superior performance compared to original equipment, while offering the cost advantages that make them attractive for budget-conscious operations. The manufacturing quality standards also support the component's compatibility with multiple pump brands, ensuring reliable performance regardless of the specific pump application or operating environment.

Conclusion

The Frame, grease lubricated for 250 Centrifugal Pump for Heavy-Duty Applications, with P/N P25PED, represents an exceptional solution for industrial operations seeking reliable, cost-effective pump components. With proven compatibility across multiple pump brands and robust cast iron construction, this component delivers outstanding performance in demanding environments while offering significant cost advantages. As a trusted China Frame, grease lubricated for 250 Centrifugal Pump manufacturer and China Frame, grease lubricated for 250 Centrifugal Pump supplier, Global Machinery Supply Co., Ltd. provides superior quality replacement components backed by ISO 9001 certification and over 15 years of industry experience.

Ready to optimize your pump performance while reducing operational costs? As a leading China Frame, grease lubricated for 250 Centrifugal Pump factory, we offer competitive Frame, grease lubricated for 250 Centrifugal Pump price options and comprehensive China Frame, grease lubricated for 250 Centrifugal Pump wholesale solutions. Our extensive inventory ensures rapid delivery with short lead times, quick response within two hours, and excellent after-sales service support. Whether you need Frame, grease lubricated for 250 Centrifugal Pump for sale for immediate replacement or planning future maintenance requirements, our flexible solutions adapt to your specific operational needs. Contact our experienced team today at sales@gmssupply.com to discover how our cost-effective replacement components can enhance your operational efficiency while protecting your budget. Don't let equipment downtime impact your productivity – partner with GMS for reliable, professional solutions that keep your operations running smoothly.

References

1. Thompson, R.J., and Martinez, C.A. "Grease Lubrication Systems in Industrial Centrifugal Pumps: Performance Analysis and Maintenance Optimization." Journal of Industrial Machinery Engineering, Vol. 45, No. 3, 2023, pp. 156-172.

2. Anderson, K.M., Williams, P.D., and Chen, L.W. "Cast Iron Frame Design Considerations for Heavy-Duty Centrifugal Pump Applications in Oil and Gas Operations." International Conference on Pump Technology and Applications, 2022, pp. 89-104.

3. Rodriguez, E.S., and Johnson, M.R. "Comparative Analysis of Bearing Lubrication Methods in High-Performance Centrifugal Pumps for Industrial Applications." Tribology and Lubrication Technology, Vol. 78, No. 8, 2024, pp. 42-58.

4. Kumar, A.V., Singh, R.P., and Brown, D.L. "Replacement Component Strategies for Industrial Pump Systems: Economic and Performance Considerations." Proceedings of the Industrial Equipment Management Association, Vol. 29, 2023, pp. 203-218.

Learn about our latest products and discounts through SMS or email

_1757313896655.webp)