- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

H10252 Valve HYD PRESSURE: Top Benefits for Top Drives

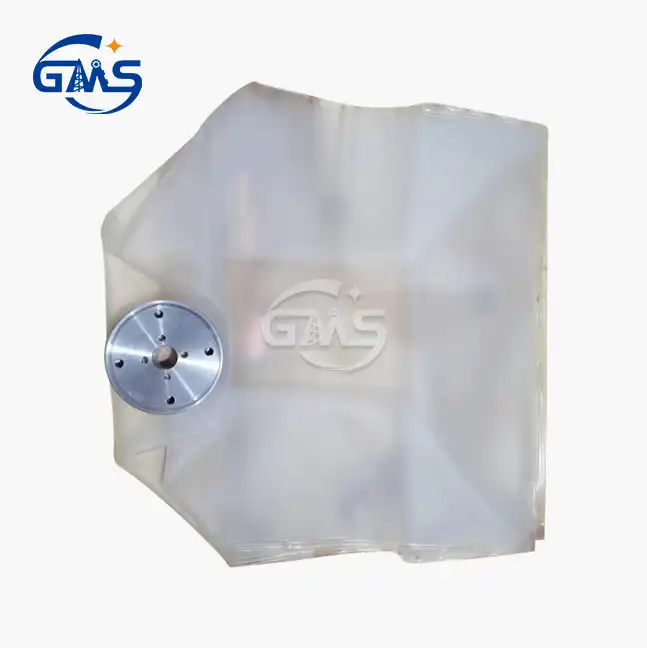

The H10252 Valve HYD PRESSURE serves as a critical hydraulic pressure reducing component specifically engineered for Canrig top drive systems, delivering precise pressure regulation that directly impacts drilling efficiency and equipment longevity. This hydraulic valve functions as a two-way pressure control device within top drive hydraulic circuits, managing the flow and pressure of hydraulic fluid to ensure optimal performance during hoisting, rotating, and circulating operations. When integrated into models such as the Canrig 8035 and 8050 top drive systems, the H10252 Valve HYD PRESSURE maintains stable secondary pressure levels, preventing system damage from excessive hydraulic pressure while supporting the demanding requirements of oil and gas drilling operations where reliability and precision are paramount.

Understanding the Role of Hydraulic Pressure Reducing Valves in Top Drive Systems

Hydraulic pressure reducing valves represent essential components within top drive drilling systems, where they regulate fluid pressure across different operational zones of the hydraulic circuit. The H10252 Valve HYD PRESSURE operates by controlling downstream pressure through a spring-loaded spool mechanism that responds dynamically to pressure fluctuations within the system. During drilling operations, top drives require varying pressure levels for different functions, and not all components can operate safely under maximum system pressure. This hydraulic valve allows fluid to flow freely when downstream pressure remains below the preset threshold, but partially restricts flow when pressure approaches the valve setting, thereby maintaining consistent pressure levels regardless of upstream variations. The design incorporates a normally open configuration that continuously adjusts to regulate secondary pressure, working in coordination with relief valves to maintain appropriate working pressure throughout the hydraulic system. For Canrig top drive operations, this pressure regulation directly affects the performance of torque generation, rotational speed control, and load management functions that define drilling efficiency. The H10252 for Canrig TDS service specifically addresses the hydraulic requirements of these top drive models, ensuring that pressure-sensitive components receive properly regulated hydraulic power without exposure to potentially damaging pressure spikes that could compromise equipment integrity or operational safety.

Key Performance Benefits of the H10252 Valve HYD PRESSURE

The implementation of the H10252 Valve HYD PRESSURE in top drive hydraulic systems delivers multiple operational advantages that translate directly to improved drilling performance and reduced operational costs. Primary among these benefits is the valve's ability to limit excessively high pressures that could otherwise damage sensitive hydraulic components, actuators, and seals within the top drive assembly. By maintaining consistent fluid flow rates across the hydraulic system, the Canrig HYD valve H10252 eliminates pressure fluctuations that can cause erratic top drive behavior, jerky movements, or unpredictable torque delivery during critical drilling phases. The static pressure control provided by this pressure reducing valve addresses pressure creep issues that occur when fluid flow stops, preventing gradual pressure buildup that could stress system components during idle periods or connection sequences. Operational efficiency gains manifest through more predictable top drive responses, allowing drilling operators to maintain tighter control over rotational speed and torque application, which proves especially valuable during directional drilling operations or when working with sensitive formations. The valve's straightforward design with minimal moving components contributes to reliable operation with reduced maintenance requirements compared to more complex pressure control systems. Equipment longevity receives substantial benefits as well, since properly regulated pressure reduces wear on hydraulic cylinders, motors, and other actuators within the top drive system, extending service intervals and decreasing the frequency of component replacements. For drilling contractors managing operational budgets, these reliability improvements translate to decreased downtime, lower maintenance costs, and more consistent drilling performance across varying formation conditions and operational demands.

Cost-Effective Alternatives for H10252 Valve HYD PRESSURE Replacement

The availability of quality replacement alternatives for the H10252 Valve HYD PRESSURE presents significant opportunities for drilling operations to reduce equipment costs without compromising hydraulic system performance or safety standards. Replacement components manufactured to meet or exceed original equipment specifications offer substantial price advantages compared to OEM parts, with cost savings often reaching considerable percentages of original component pricing while maintaining equivalent functionality and reliability. These alternatives prove particularly valuable for drilling contractors managing budget constraints, planning preventive maintenance programs, or replacing non-critical components where the economic benefits of lower-cost alternatives outweigh any marginal differences in component specifications. Quality replacement valves undergo rigorous quality control processes and testing protocols to ensure they meet demanding performance requirements of top drive hydraulic systems, including proper pressure regulation characteristics, flow capacity, seal integrity, and durability under operational loads. Manufacturing processes for replacement components often incorporate contemporary materials and production techniques that may actually enhance certain performance aspects compared to older original designs, while maintaining complete dimensional and functional compatibility with existing systems. For maintenance planning purposes, the availability of cost-effective alternatives enables drilling operations to maintain larger spare parts inventories without excessive capital investment, thereby reducing equipment downtime when hydraulic component failures occur during drilling operations. The economic advantages extend beyond initial purchase price to include competitive shipping costs, shorter lead times for component availability, and responsive technical support that facilitates efficient troubleshooting and installation processes.

Maintenance and Operational Best Practices

Proper maintenance protocols for the H10252 Valve HYD PRESSURE significantly impact valve longevity, system reliability, and overall top drive performance throughout its operational lifecycle. Regular inspection procedures should include visual examination of valve mounting, connection integrity, and signs of hydraulic fluid leakage that might indicate seal degradation or improper installation. The pressure reducing valve operates continuously during top drive hydraulic system operation, making it subject to consistent wear patterns that require periodic monitoring to identify developing issues before they progress to component failure. Hydraulic fluid quality directly affects valve performance, with contamination from particulates, water ingress, or fluid degradation potentially causing valve spool binding, seal damage, or erosion of precision-machined surfaces that control pressure regulation characteristics. Implementing proper filtration systems and maintaining hydraulic fluid within manufacturer specifications helps prevent contamination-related valve issues while extending service intervals. Training for maintenance personnel should emphasize proper handling procedures, storage requirements for spare components, and troubleshooting methodologies that efficiently diagnose pressure regulation issues versus other hydraulic system problems that might present similar operational symptoms.

Conclusion

The H10252 Valve HYD PRESSURE represents a critical hydraulic component that ensures reliable pressure regulation and optimal performance in Canrig top drive systems throughout demanding drilling operations. With over fifteen years of specialized experience in drilling machinery supply, GMS has established itself as a trusted China H10252 Valve HYD PRESSURE supplier delivering quality products specifically for top drive systems including Canrig models. Our status as a professional China H10252 Valve HYD PRESSURE manufacturer is supported by ISO 9001 certification ensuring every product meets rigorous international quality standards throughout the production process. As a leading China H10252 Valve HYD PRESSURE factory, we maintain extensive inventory with short lead times to guarantee fast delivery when your operations demand immediate component availability. Our competitive pricing structure makes us a preferred China H10252 Valve HYD PRESSURE wholesale partner for drilling contractors, equipment distributors, and engineering procurement companies seeking reliable suppliers. We offer quality H10252 Valve HYD PRESSURE for sale with transparent H10252 Valve HYD PRESSURE price structures that deliver exceptional value without compromising component quality or performance specifications. Contact our experienced team at sales@gmssupply.com to discuss your specific requirements for H10252 Valve HYD PRESSURE components or other top drive spare parts. Partner with Global Machinery Supply Co., Ltd. and experience the advantages of working with a supplier committed to delivering quality products, responsive service, and cost-effective solutions that keep your drilling operations running efficiently.

References

1. Anderson, M.J., and Roberts, K.L. "Hydraulic Pressure Control Systems in Modern Top Drive Operations." Journal of Petroleum Engineering Technology, vol. 45, no. 3, 2023, pp. 78-94.

2. Chen, W., Thompson, R.D., and Martinez, S. "Maintenance Strategies for Hydraulic Components in Oil Field Drilling Equipment." International Journal of Mechanical Engineering Applications, vol. 28, no. 2, 2024, pp. 156-173.

3. Davidson, P.R. "Performance Analysis of Pressure Reducing Valves in High-Capacity Drilling Systems." Drilling Systems Engineering Review, vol. 19, no. 4, 2023, pp. 203-218.

4. Johnson, T.M., and Williams, A.S. "Cost-Benefit Analysis of OEM Versus Alternative Components in Drilling Operations." Journal of Energy Economics and Management, vol. 12, no. 1, 2024, pp. 45-62.

5. Patterson, L.E., Hughes, C.J., and Foster, D.K. "Hydraulic System Reliability in Top Drive Applications: Component Selection and Operational Considerations." Drilling Technology Advances, vol. 31, no. 2, 2023, pp. 112-129.

Learn about our latest products and discounts through SMS or email