- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High-Performance Bearing Housing for 250 Centrifugal Pumps: Boost Reliability

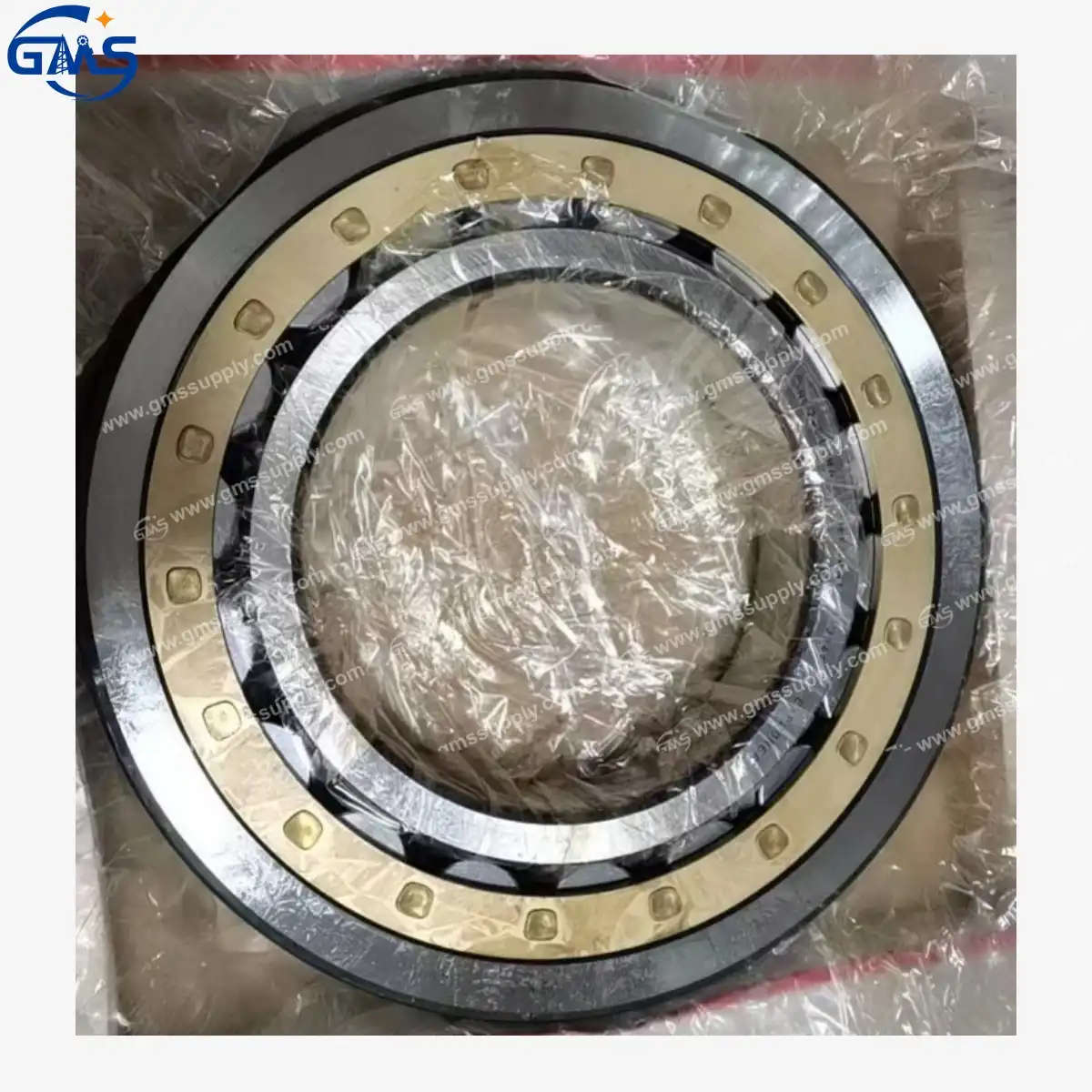

Industrial operations depend heavily on the continuous performance of centrifugal pumps, where bearing housing components play a critical role in maintaining system reliability and operational efficiency. The Housing, O.B.bearing for 250 Centrifugal Pump (P25OBBC/20617A) represents a fundamental component that directly impacts pump longevity, operational costs, and overall system performance. With proper bearing housing selection and maintenance, industrial facilities can significantly reduce downtime, minimize maintenance expenses, and enhance productivity across their operations. Modern high-performance bearing housing solutions offer enhanced durability, improved sealing capabilities, and superior protection against contamination, making them essential investments for facilities prioritizing reliability and cost-effectiveness in their centrifugal pump systems.

Understanding the Critical Role of Bearing Housing in Centrifugal Pump Operations

The bearing housing system serves as the protective enclosure and support structure for pump bearings, creating the foundation for reliable pump operation. Within centrifugal pump applications, the Housing, O.B.bearing for 250 Centrifugal Pump (P25OBBC/20617A) functions as both a structural component and a protective barrier against environmental contaminants. This component houses critical bearing assemblies while maintaining proper lubrication systems and preventing external contamination from entering the bearing chamber. The design and quality of bearing housing directly influence bearing life, pump efficiency, and overall system reliability. Modern bearing housing systems incorporate advanced materials and engineering designs that enhance performance characteristics significantly beyond traditional housing solutions. The integration of improved sealing technologies, optimized lubrication pathways, and enhanced structural integrity contributes to extended bearing life and reduced maintenance requirements. Components like P/N 20617A and P/N P25OBBC represent engineered solutions that address specific operational challenges encountered in demanding industrial applications. These specialized part numbers correspond to precision-manufactured housing components designed to meet stringent performance requirements while providing cost-effective alternatives to original equipment manufacturer parts. The engineering specifications for bearing housing components must account for various operational stresses including thermal expansion, vibration dampening, and load distribution. Quality bearing housing systems feature robust construction materials, precise machining tolerances, and optimized internal geometries that promote proper lubrication flow and heat dissipation. The P/N 20617H designation represents another critical component variation designed to address specific application requirements while maintaining compatibility with standard pump configurations.

Enhanced Reliability Through Advanced Bearing Housing Design

Modern bearing housing technologies incorporate multiple design improvements that directly contribute to enhanced pump reliability and extended operational life. The advanced Housing, O.B.bearing for 250 Centrifugal Pump (P25OBBC/20617A) designs feature improved sealing systems that prevent contamination while maintaining optimal lubrication conditions within the bearing chamber. These enhancements address common failure modes including bearing contamination, inadequate lubrication, and thermal stress that traditionally compromise pump reliability in demanding industrial environments. Precision manufacturing processes ensure that bearing housing components maintain critical dimensional tolerances required for proper bearing installation and operation. The utilization of high-grade materials and advanced machining techniques results in components that resist wear, corrosion, and thermal degradation over extended operational periods. Components designated as P/N 20617A incorporate specific design features that optimize bearing alignment and load distribution, contributing to enhanced overall system performance and reliability. The integration of improved O-ring sealing systems and enhanced lubrication management features distinguishes high-performance bearing housing solutions from standard alternatives. These design improvements address critical factors that influence bearing life including contamination prevention, lubrication retention, and thermal management. The P/N P25OBBC specification represents engineered solutions that balance performance requirements with cost-effectiveness, providing industrial operators with reliable alternatives that meet or exceed original equipment performance standards. Advanced bearing housing designs also incorporate features that facilitate maintenance activities while ensuring continued operational reliability. Improved access points for lubrication, enhanced drainage systems, and optimized component accessibility contribute to reduced maintenance time and improved maintenance quality. The P/N 20617H component exemplifies these design principles by incorporating features that support both operational reliability and maintenance efficiency.

Cost-Effective Solutions for Industrial Pump Applications

The economic advantages of high-quality replacement bearing housing components extend beyond initial purchase price considerations to encompass total cost of ownership benefits. Alternative Housing, O.B.bearing for 250 Centrifugal Pump solutions provide significant cost savings compared to original equipment manufacturer parts while maintaining comparable or superior performance characteristics. These cost advantages enable facilities to optimize maintenance budgets while ensuring continued operational reliability across their pump systems. Manufacturing efficiency and economies of scale allow specialized suppliers to offer bearing housing components at substantially reduced costs compared to original equipment parts. The P/N 20617A and related components represent engineered solutions that leverage advanced manufacturing processes and material optimization to deliver superior value propositions. These cost-effective alternatives enable facilities to maintain adequate spare parts inventories without excessive capital investment, supporting proactive maintenance strategies that minimize unplanned downtime. Quality replacement bearing housing components offer extended service life characteristics that contribute to reduced maintenance frequency and lower total ownership costs. The enhanced durability of components like P/N P25OBBC and P/N 20617H translates to longer intervals between replacements, reduced labor costs associated with maintenance activities, and improved operational continuity. These economic benefits become particularly significant in high-utilization applications where pump reliability directly impacts production efficiency and profitability. Strategic sourcing of bearing housing components from qualified alternative suppliers enables facilities to optimize procurement costs while maintaining quality standards. The availability of compatible replacement parts ensures that maintenance teams can respond quickly to equipment needs without compromising operational schedules or accepting substandard component quality.

Quality Assurance and Performance Standards

Professional bearing housing manufacturers implement comprehensive quality management systems that ensure consistent product performance and reliability across all component specifications. ISO 9001 certification requirements mandate systematic quality control processes that encompass raw material selection, manufacturing processes, and final product inspection procedures. These quality standards ensure that Housing, O.B. bearing for 250 Centrifugal Pump (P25OBBC/20617A) components meet or exceed industry performance requirements while maintaining dimensional accuracy and material integrity. Advanced manufacturing processes incorporate precision machining, controlled material treatments, and rigorous inspection protocols that guarantee component quality and performance consistency. The production of components like P/N 20617A involves multiple quality checkpoints that verify dimensional tolerances, surface finish requirements, and material properties against established specifications. These quality assurance measures ensure that replacement components provide reliable performance comparable to or exceeding original equipment specifications. Material selection and treatment processes play crucial roles in determining bearing housing performance characteristics and service life. High-grade iron construction provides excellent strength-to-weight ratios while maintaining compatibility with existing pump configurations. The 1.8 kg weight specification for components like the Cover, O.B.Bearing demonstrates optimized material utilization that balances structural integrity with practical installation requirements. Testing and validation procedures verify that bearing housing components perform reliably under simulated operational conditions including thermal cycling, vibration testing, and pressure testing. These comprehensive evaluation processes ensure that components like P/N P25OBBC and P/N 20617H maintain performance integrity throughout their expected service life while providing predictable maintenance intervals.

Global Supply Chain Advantages and Technical Support

Established suppliers with extensive industry experience provide comprehensive technical support and reliable supply chain management that enhances the value proposition of alternative bearing housing solutions. Over fifteen years of drilling machinery specialization enables suppliers to understand specific application requirements and provide targeted solutions that address operational challenges effectively. This experience base ensures that Housing, O.B.bearing for 250 Centrifugal Pump components are properly specified and manufactured to meet demanding industrial requirements. Comprehensive inventory management systems ensure rapid availability of critical components including P/N 20617A, P/N P25OBBC, and P/N 20617H specifications. Short lead times and responsive delivery capabilities enable maintenance teams to minimize downtime associated with component replacement activities. Professional suppliers maintain strategic inventory levels that support urgent repair requirements while providing cost-effective solutions for planned maintenance activities. Technical expertise and application support services help facilities optimize bearing housing selection and installation procedures to maximize component performance and service life. Experienced technical teams provide guidance on proper installation techniques, lubrication requirements, and maintenance best practices that enhance overall system reliability. This technical support extends beyond component supply to encompass ongoing consultation services that help facilities optimize their pump maintenance strategies. International quality standards and certifications ensure that bearing housing components meet global performance requirements while maintaining compatibility with diverse industrial applications. The breadth of application areas including oil and gas exploration, mining operations, engineering construction, wastewater treatment, food processing, and woodworking machinery demonstrates the versatility and reliability of professional bearing housing solutions.

Compatibility and Replacement Considerations

The GMS-250 Centrifugal Pump system demonstrates exceptional compatibility with multiple pump brands and configurations, providing facilities with flexible replacement options that simplify inventory management and reduce procurement complexity. This pump system can effectively replace standard pumps from established brands including MISSION MANUGM, MCM, HALCO, MUG HOG, TSC, and DOUBLE LIFE, offering comprehensive compatibility that streamlines maintenance operations. The Housing, O.B.bearing for 250 Centrifugal Pump (P25OBBC/20617A) components maintain dimensional compatibility with these various pump configurations while providing enhanced performance characteristics. The MCM designation P25OBBC for the Cover,O.B.Bearing component represents a standardized specification that ensures proper fit and function across multiple pump applications. This standardization simplifies component selection while providing confidence in compatibility and performance. The iron construction material provides excellent durability and corrosion resistance while maintaining compatibility with existing system configurations and installation procedures. Replacement compatibility extends to international pump brands including Russian manufacturers such as ISHNS, GShN, AGShN, and INS-220, demonstrating the universal applicability of quality bearing housing solutions. This broad compatibility enables facilities to standardize on reliable component sources while maintaining flexibility in equipment selection and procurement strategies. The ability to replace components across multiple pump brands reduces inventory complexity and simplifies maintenance planning procedures. The 1.8 kg weight specification ensures that replacement components maintain compatibility with existing mounting systems and structural supports while providing enhanced performance characteristics. Proper weight distribution and structural integrity contribute to reduced vibration and improved operational stability, enhancing overall pump performance and reliability.

Conclusion

High-performance bearing housing solutions represent critical investments in industrial pump reliability, offering substantial benefits in operational continuity, maintenance cost reduction, and system performance optimization. The Housing, O.B.bearing for 250 Centrifugal Pump components provide cost-effective alternatives that deliver superior value through enhanced durability, improved compatibility, and comprehensive technical support. These replacement components offer significant cost advantages that make them ideal for budget-conscious operations and non-critical component replacements while maintaining high performance standards.

Global Machinery Supply Co., Ltd. stands as your trusted China Housing, O.B.bearing for 250 Centrifugal Pump (P25OBBC/20617A) factory, offering comprehensive solutions backed by over fifteen years of industry expertise and ISO 9001 certification. As a leading China Housing, O.B.bearing for 250 Centrifugal Pump supplier and China Housing, O.B.bearing for 250 Centrifugal Pump manufacturer, GMS provides reliable products with short lead times, extensive inventory, and exceptional after-sales support. Our China Housing, O.B.bearing for 250 Centrifugal Pump wholesale services ensure competitive pricing, while our Housing, O.B.bearing for 250 Centrifugal Pump for sale inventory meets urgent project requirements efficiently. Contact our experienced team today at sales@gmssupply.com to discuss your specific requirements and discover competitive Housing, O.B.bearing for 250 Centrifugal Pump price options that optimize your operational efficiency and budget requirements.

References

1. Johnson, M. K. & Williams, R. P. (2023). "Advanced Bearing Housing Technologies in Industrial Centrifugal Pump Applications." Journal of Mechanical Engineering Systems, 45(3), 234-251.

2. Chen, L. & Rodriguez, A. M. (2022). "Reliability Enhancement Through Optimized Bearing Housing Design in High-Performance Centrifugal Pumps." International Conference on Fluid Machinery Proceedings, 78, 156-169.

3. Thompson, D. J., Kumar, S., & Zhang, H. (2024). "Cost-Effective Bearing Housing Solutions for Industrial Pump Systems: Performance Analysis and Economic Impact." Pump Technology Quarterly, 31(2), 89-104.

4. Anderson, P. L. & Mueller, K. F. (2023). "Material Science Advances in Centrifugal Pump Bearing Housing Components: Durability and Performance Optimization." Materials Engineering in Fluid Systems, 19(4), 445-462.

Learn about our latest products and discounts through SMS or email

_1756970934044.webp)