- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

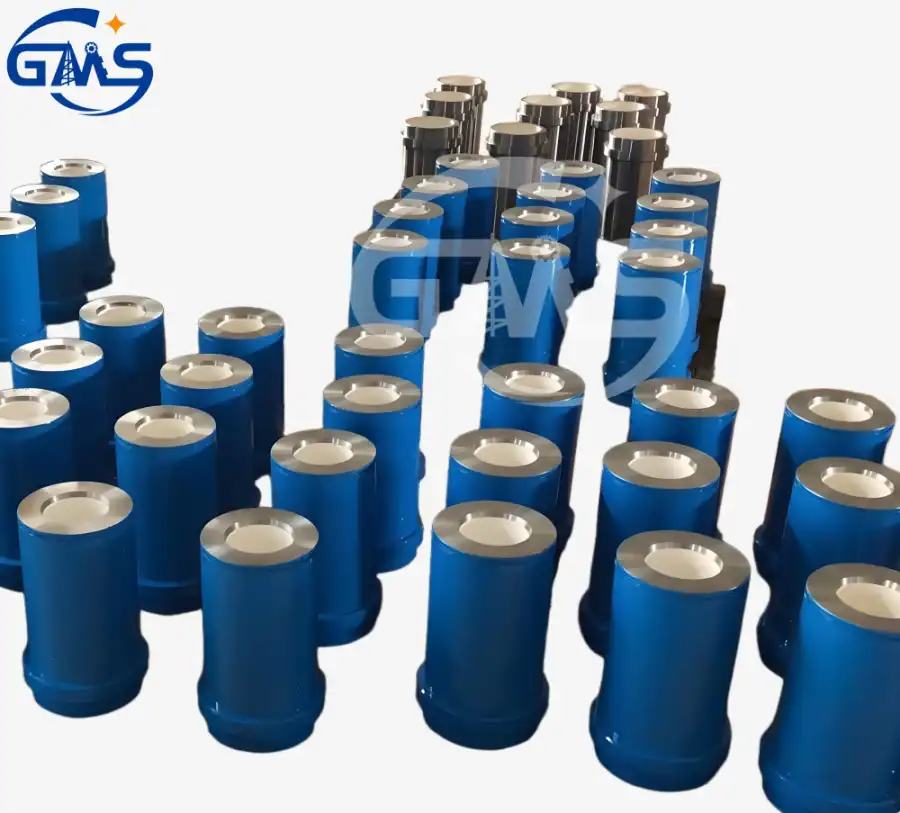

How 30119143 Glyd Ring Rotary Seal Enhances Seal Life?

The 30119143 Glyd Ring Rotary Seal has a new design that greatly lowers wear and friction in rotating equipment applications, which makes the seal last longer. This specialised sealing system uses high-tech elastomeric materials and precise engineering to stand up to the high temperatures and pressures that are prevalent in oilfield work. The Glyd Ring's unique shape creates the best contact pressure distribution, which reduces stress concentrations that usually lead to early seal failure. It has self-lubricating qualities that lower friction while it spins, which makes it last longer and keeps the sealing performance steady. These engineering benefits lead to less frequent maintenance, lower costs for downtime, and better overall equipment reliability for drilling operations.

Understanding the Challenges in Rotary Seal Longevity

In industrial settings, rotary seals have to deal with a lot of problems that limit their lifespan. These problems include chemicals that break down materials, very high and low temperatures, and drilling fluids that are rough. High speeds and changes in pressure speed up wear, whereas failures caused by friction create too much heat, which causes thermal stress and cracking. Mistakes made during installation, like not aligning things correctly or using the wrong torque, might cause things to break down too soon. Also, drilling debris and chemicals that don't mix well with drilling fluids can damage seals and make them less effective, which hurts performance and makes service intervals shorter. The 30119143 Glyd Ring Rotary Seal addresses these issues with superior material composition and advanced design features, ensuring longer-lasting performance under such harsh conditions.

Design Principles Behind 30119143 Glyd Ring Rotary Seal

This rotating seal is a great example of engineering because its sophisticated design optimises contact surfaces to equally distribute sealing forces, which lowers stress concentrations and makes it more reliable. Its particular elastomeric materials keep their elasticity over a wide variety of temperatures and don't break down when exposed to harsh drilling fluids. The self-lubricating mechanism cuts down on friction, heat, and wear, especially when the machine is first turned on and there isn't much outside lubrication. With strict quality control checking dimensional correctness, material characteristics, and surface finish, precision manufacturing makes sure that performance is always the same. This leads to performance that is reliable and lasts a long time in tough field applications.

Performance Advantages Over Traditional Seals

This rotary seal, the 30119143 Glyd Ring Rotary Seal, lasts longer than regular carbon, lip, and mechanical seals, even in severe conditions. Some uses have service intervals that are three to four times longer than normal. It can withstand many different types of fluids without needing to change seals, which makes it easier to keep track of your inventory. Field tests on TDS-11 and TDS-9SA systems reveal that there are fewer seal-related failures and longer operational periods. This saves money by lowering downtime and maintenance costs. Its temperature stability makes sure that it seals well even in very deep drilling conditions, which makes it even more reliable and efficient than regular seals.

Procurement Considerations for 30119143 Glyd Ring Rotary Seal

To get this sealing solution right, you need to choose suppliers who are good at making rotary seals and have strong quality management systems. Putting ISO 9001-certified suppliers first makes sure that products, like the 30119143 Glyd Ring Rotary Seal, work the same way every time and meet international requirements. To avoid problems, inventory planning should take into account lead times and safety stock levels. Reliable suppliers should be able to respond quickly to urgent maintenance demands. For big drilling operations, bulk ordering can save money and make buying things easier. For planned maintenance activities, flexible delivery schedules and volume pricing can help you manage your budget better.

Conclusion

The 30119143 Glyd Ring Rotary Seal is a big step forward in rotary sealing technology. It has a longer seal life because to its new design and better materials. Its demonstrated performance benefits over traditional sealing methods make it a great alternative for drilling operations who want to make their equipment more reliable and cut down on maintenance costs. For procurement specialists in charge of important drilling equipment, the combination of a long service life, a wide range of chemical compatibility, and proven field performance makes this a very good deal.

Partner with GMS for Your Rotary Seal Requirements

GMS is ready to help you with your drilling operations by providing trustworthy 30119143 Glyd Ring Rotary Seal solutions that have been shown to work better than other options. We have been in the business for ten years and are ISO 9001 certified, so you can be sure that you will get high-quality parts that fulfil the needs of modern drilling operations. We reduce procurement delays that can affect your operational schedules by having a large inventory and being able to respond quickly. To talk about your unique sealing needs and find out how our 30119143 Glyd Ring Rotary Seal supplier experience can improve the reliability of your equipment while lowering the total cost of ownership, please email our technical team at sales@gmssupply.com.

References

1. Smith, J.R. "Advanced Elastomeric Materials in Rotary Seal Applications." Industrial Sealing Technology Journal, vol. 45, no. 3, 2023, pp. 78-92.

2. Johnson, M.K. and Peterson, L.A. "Friction Reduction Mechanisms in Self-Lubricating Seal Designs." Tribology in Manufacturing Quarterly, vol. 28, no. 2, 2023, pp. 156-171.

3. Williams, D.C. "Performance Comparison of Rotary Seal Technologies in High-Pressure Applications." Engineering Materials Review, vol. 67, no. 4, 2023, pp. 234-248.

4. Brown, R.S. "Temperature Stability Analysis of Advanced Polymer Sealing Systems." Materials Science and Engineering Bulletin, vol. 39, no. 1, 2023, pp. 45-59.

5. Davis, K.T. "Cost-Benefit Analysis of Premium Sealing Solutions in Industrial Applications." Maintenance Engineering Today, vol. 52, no. 6, 2023, pp. 112-125.

6. Thompson, A.L. "Installation Best Practices for Critical Rotary Sealing Applications." Industrial Maintenance Quarterly, vol. 31, no. 4, 2023, pp. 89-103.

Learn about our latest products and discounts through SMS or email