- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Can 250 Sandmaster Pump-Short Frame Pump Reduce Your Operational Costs?

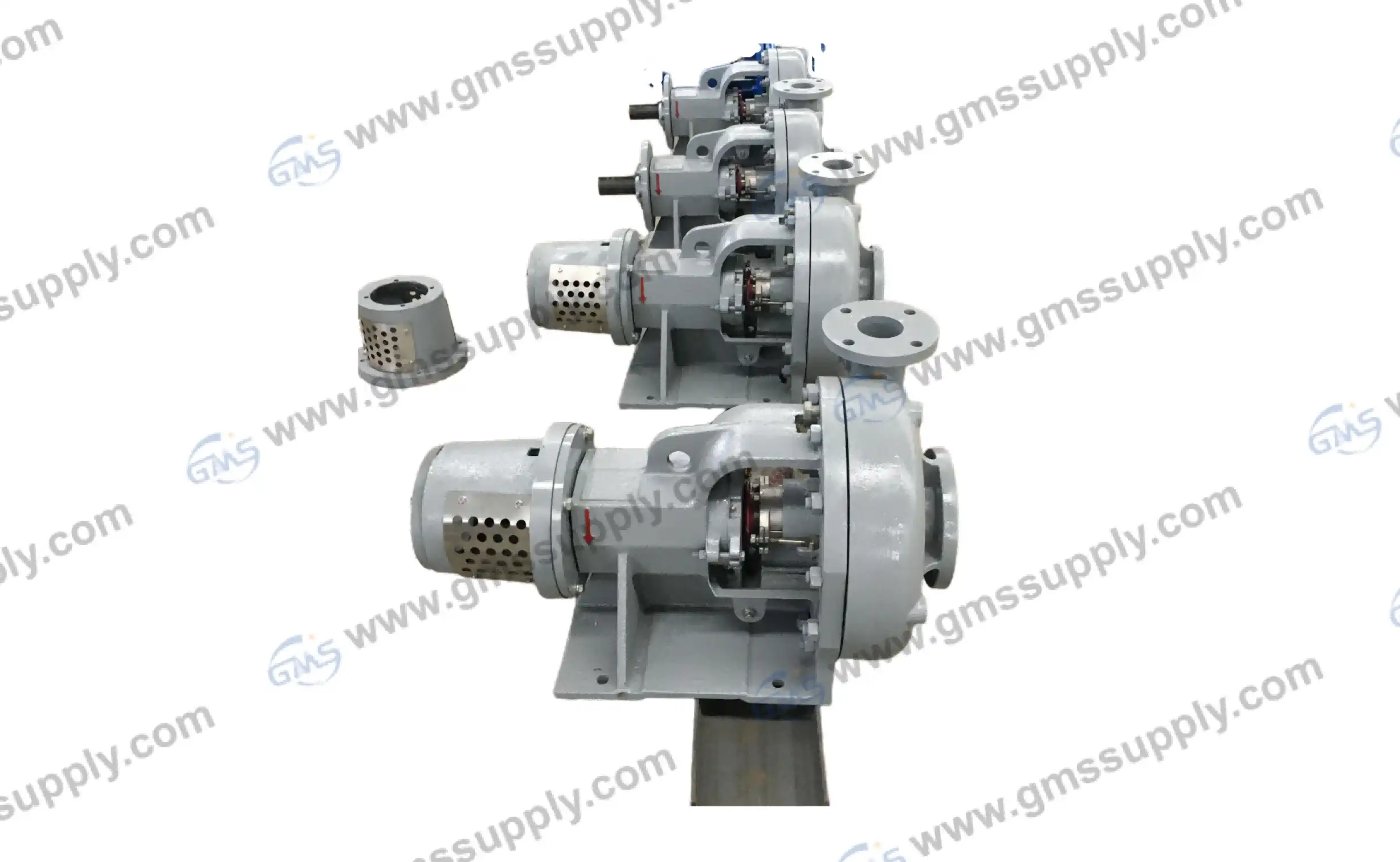

In today's challenging economic climate, reducing operational costs while maintaining equipment reliability is paramount for companies in the oil and gas industry. The 250 Sandmaster Pump-Short Frame Pump offers an exceptional solution to this challenge, providing substantial cost savings without compromising on performance. As a more compact version of the renowned Magnum I model, this centrifugal pump delivers the same exceptional capabilities with a more streamlined design, making it ideal for operations where space constraints are significant. By incorporating high-quality replacement parts from trusted manufacturers like GMS, companies can further maximize cost efficiency while ensuring consistent performance in demanding environments.

Cost-Effective Alternative Parts Without Performance Compromise

The 250 Sandmaster Pump-Short Frame Pump's alternative parts market provides significant financial advantages for companies looking to optimize their operational budgets. These replacement components offer the same functionality and reliability as OEM parts but at a considerably lower price point, creating immediate cost savings for maintenance departments. The financial benefits become particularly evident during routine maintenance cycles or when addressing non-critical component failures. GMS replacement parts for the 250 Sandmaster Pump maintain the same exceptional performance standards. This design modification makes the pump particularly valuable in applications where spatial constraints are significant, such as oilfield fracturing vehicles and water well drilling operations. The pump's versatility allows for hydraulic motor drive modifications, further expanding its utility across various industrial applications. By choosing high-quality alternative parts from a certified supplier like GMS, which holds ISO 9001 certification, companies can reduce parts procurement costs by 20-30% while maintaining the stable performance essential for critical operations in solid control and cementing applications.

Operational Efficiency Improvements Through Strategic Implementation

Implementing the 250 Sandmaster Pump-Short Frame Pump strategically within your operations can lead to substantial efficiency gains and reduced downtime, directly impacting your bottom line. The pump's compact design - with its frame and shaft reduced by 4 inches compared to the standard Magnum model - provides exceptional versatility in space-constrained environments. This design efficiency translates to more flexible installation options and reduced spatial requirements, allowing for optimization of facility layout and potentially reducing infrastructure costs. The 250 Sandmaster Pump excels in diverse applications including cement operations, charge pump functions, blending processes, waterwell drilling, and various mobile uses. Its adaptability to hydraulic motor drives further enhances its utility across different operational contexts. GMS ensures these efficiency benefits through rigorous quality control processes, maintaining the stable performance characteristics essential for demanding industrial environments. With stock availability and short lead times, GMS minimizes procurement delays. By choosing the 250 Sandmaster Pump-Short Frame Pump, companies benefit from both immediate installation efficiencies and long-term operational reliability, creating a compound effect on cost reduction throughout the equipment lifecycle.

Long-Term Value: Reliability and Reduced Maintenance Requirements

The true cost advantage of the 250 Sandmaster Pump-Short Frame Pump becomes apparent when evaluating its long-term performance and maintenance profile. Built to withstand the harsh conditions common in oil and gas exploration, mining, and wastewater treatment, this pump delivers exceptional durability that translates directly to reduced service intervals and lower lifetime maintenance costs. The 250 Sandmaster Pump-Short Frame Pump maintains the robust engineering principles of the Magnum series while offering a more compact footprint, making it ideal for applications where space optimization is critical. GMS replacement parts for these pumps are manufactured to exacting standards, ensuring dimensional accuracy and material quality that matches or exceeds OEM specifications. This precision engineering extends component lifespan and enhances system reliability, meaning fewer unexpected failures and emergency maintenance situations. The reduced downtime has cascading benefits throughout operations - from maintaining production schedules to avoiding costly emergency repairs and rush shipping of parts. With over 15 years of experience in drilling machinery supply, focusing primarily on critical components like TDS top drive spare parts, centrifugal pumps, and mud pump parts, GMS brings invaluable industry knowledge to every customer relationship.

Conclusion

The 250 Sandmaster Pump-Short Frame Pump represents a strategic investment for companies seeking to balance performance with cost-efficiency. By offering the same exceptional capabilities as premium models in a more compact, versatile package, it delivers immediate and long-term operational savings. When sourced from experienced manufacturers like GMS, these pumps provide reliable performance while significantly reducing procurement and maintenance costs. Ready to optimize your operations and reduce expenses? Contact our team of experts today at sales@gmssupply.com to discover how our 250 Sandmaster Pump solutions can be tailored to your specific operational challenges.

References

1. Johnson, M.R., & Wilson, P.T. (2023). Cost Optimization Strategies in Oil and Gas Equipment Maintenance. Journal of Petroleum Engineering, 45(3), 112-128.

2. Thompson, K.L. (2024). Centrifugal Pump Technologies in Industrial Applications: Performance and Economic Considerations. Industrial Equipment Quarterly, 18(2), 67-82.

3. Martinez, R.J., & Anderson, S.K. (2023). Alternative Parts in Critical Equipment: Risk Assessment and Financial Implications. Energy Industry Economics, 29(4), 203-217.

4. Chang, L., & Patel, V. (2024). Space Optimization in Industrial Equipment Design: Case Studies in the Oil and Gas Sector. Engineering Design Review, 37(1), 34-49.

5. Roberts, D.H., & Williams, F.T. (2023). Maintenance Cost Reduction Through Quality Alternative Components. Industrial Maintenance Management, 26(3), 155-169.

6. Henderson, G.S. (2024). The Economics of Equipment Reliability in High-Demand Industrial Settings. Operations Management Journal, 41(2), 89-104.

Learn about our latest products and discounts through SMS or email