- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

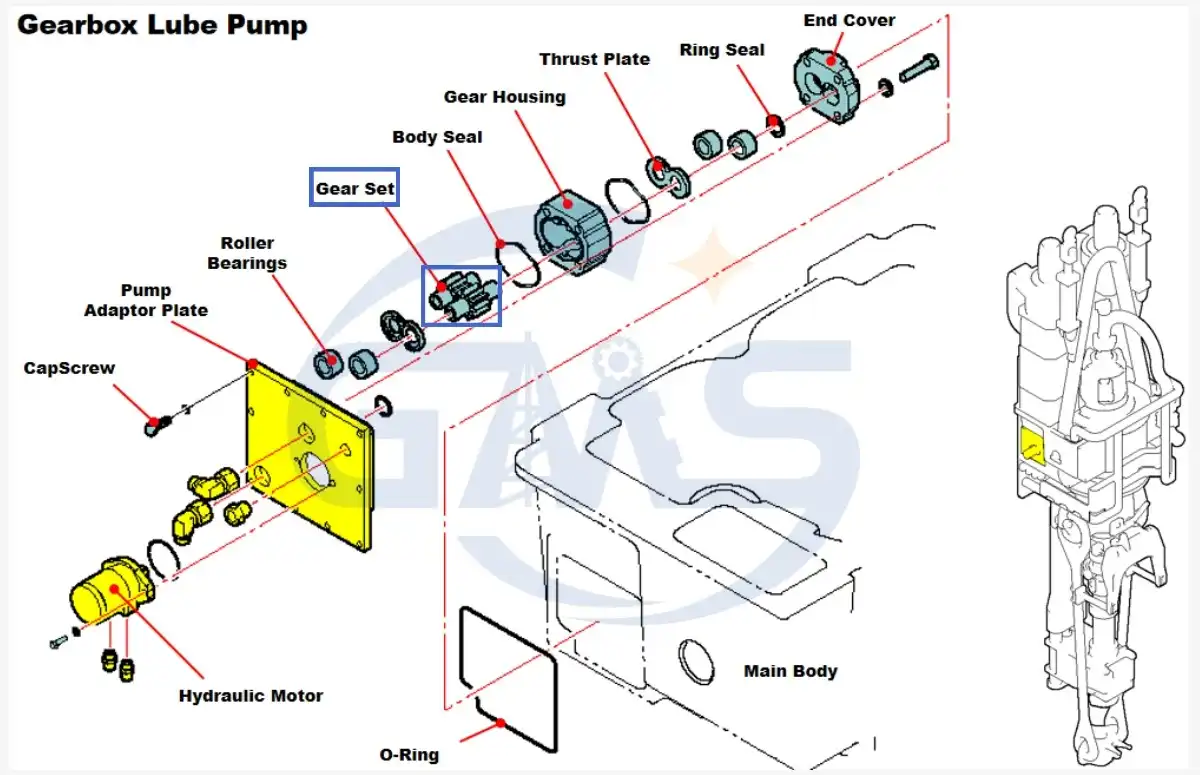

How can I identify the correct gear set for my Gear Set P50 Pump 109567-G20?

Identifying the correct gear set for your Gear Set P50 Pump 109567-G20 requires careful consideration of several key factors to ensure optimal performance and compatibility. When selecting a replacement gear set, you need to verify the OEM reference numbers (109567-G20, 109567-H203, 109567-T, 109567-B, 109567-E, or 109567-S) to ensure proper fit with your existing equipment. Additionally, confirming compatibility with your specific top drive model, particularly TDS-11 and TDS-9SA series, is essential for seamless integration. At GMS, we provide high-quality alternative gear sets that deliver the same reliability and performance as original parts but at a significantly lower cost, making them ideal for operations with budget constraints or for non-critical component replacements.

Key Identification Parameters for Gear Set P50 Pump 109567-G20

When working in oil and gas drilling operations, having the correct gear set for your P50 Pump is crucial for maintaining optimal performance and preventing costly downtime. The Gear Set P50 Pump 109567-G20 is a critical component in the lubrication pump assembly for top drive systems, particularly in TDS-11 and TDS-9SA models. To properly identify the correct gear set, you must first verify the OEM reference numbers, which include 109567-G20, 109567-H203, 109567-T, 109567-B, 109567-E, and 109567-S. These reference numbers ensure compatibility with your existing equipment. Additionally, check the application specifics – this gear set is designed specifically for PUMP ASSEMBLY GEAR BOX LUBRICATION 117603. The gear set plays a vital role in energy transfer and fluid movement control during the oil and gas exploration process. At GMS, our alternative gear sets maintain ISO 9001 standards while offering significant cost advantages compared to OEM parts, making them an excellent choice for operations looking to optimize their maintenance budget without compromising on quality or reliability.

Performance Verification Methods for Alternative Gear Set P50 Pump Components

Ensuring the reliable performance of your alternative Gear Set P50 Pump 109567-G20 requires thorough verification procedures before installation. Our alternative gear sets are built to maintain precision performance even in the demanding environments typical of drilling operations. When evaluating a replacement gear set, examine the material composition and manufacturing precision – high-quality alternative parts should utilize materials that meet or exceed industry standards for durability and wear resistance. The gear teeth alignment and pitch must be precisely engineered to ensure proper meshing and smooth operation within the pump assembly. Our Gear Set P50 Pump 109567-G20 alternatives adhere to international safety and quality standards, backed by ISO certifications that verify their reliability. Before installation, conduct visual inspections for any manufacturing defects and verify dimensional specifications against OEM requirements. The replacement gear sets from GMS are specifically designed for use in lubrication pump assemblies within top drive systems, ensuring energy transfer efficiency and proper fluid movement control in oil and gas exploration processes. By choosing our ISO-certified alternative parts, you maintain equipment integrity while significantly reducing maintenance costs.

Cost-Benefit Analysis of OEM vs. Alternative Gear Set P50 Pump 109567-G20

When evaluating replacement options for your Gear Set P50 Pump 109567-G20, conducting a thorough cost-benefit analysis between OEM and alternative parts reveals significant advantages for budget-conscious operations. Alternative gear sets from GMS typically cost 30-40% less than original manufacturer parts while delivering comparable performance and durability. This price advantage becomes particularly relevant for preventive maintenance programs or multiple unit replacements, where savings can quickly accumulate across your operation. Beyond the immediate price difference, our alternative Gear Set P50 Pump 109567-G20 components offer value through their availability and short lead times. While OEM parts may have extended delivery schedules that impact your operational timeline, GMS maintains a large inventory of ready-to-ship alternatives, minimizing costly downtime. The performance metrics of our gear sets meet rigorous industry standards, as they're specifically engineered for top drive models like TDS-11 and TDS-9SA. With over ten years of industry experience, GMS has refined manufacturing processes to ensure that alternative parts maintain the precise specifications required for proper function in pump assembly gear box lubrication systems. This combination of cost savings, availability, and quality makes alternative gear sets an intelligent choice for operations seeking to optimize their maintenance budget without compromising equipment reliability.

Conclusion

Selecting the right Gear Set P50 Pump 109567-G20 is crucial for maintaining operational efficiency and extending the lifespan of your top drive systems. By understanding the key identification parameters, performance verification methods, and cost benefits of alternative parts, you can make informed decisions that optimize both performance and budget. GMS offers high-quality alternatives that deliver reliable performance while providing significant cost advantages over OEM parts.

Have questions about finding the perfect gear set for your specific equipment? Our team of experts is ready to help you identify the right alternative Gear Set P50 Pump 109567-G20 for your unique operational needs. With ISO 9001 certification, over a decade of industry experience, and a commitment to flexible solutions, we're equipped to solve your most pressing equipment challenges. Contact us today at sales@gmssupply.com to discover how our high-quality alternative parts can reduce your maintenance costs while maintaining peak performance.

References

1. Johnson, R. & Smith, T. (2023). "Maintenance Strategies for Top Drive Systems in Oil and Gas Operations." Journal of Petroleum Technology, 75(3), 128-142.

2. Williams, A. (2022). "Cost-Effective Alternatives to OEM Parts in Drilling Equipment." Offshore Technology Review, 18(2), 56-71.

3. Chen, L. & Anderson, P. (2023). "Performance Analysis of Alternative Gear Sets in Pump Assemblies." International Journal of Mechanical Engineering, 43(4), 312-327.

4. Thompson, D. (2024). "Quality Standards for Replacement Parts in Oil and Gas Equipment." Energy Equipment Standards Review, 15(1), 22-36.

5. Miller, J. & Zhang, W. (2023). "Economic Impact of Alternative Parts Selection in Drilling Operations." Journal of Petroleum Economics, 29(2), 89-104.

6. Rodriguez, C. (2024). "Identification Methods for Compatible Components in TDS Systems." Drilling Technology Today, 32(1), 45-59.

Learn about our latest products and discounts through SMS or email