- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does the Shot Pin Assembly 30151875 Perform in Harsh Drilling Environments?

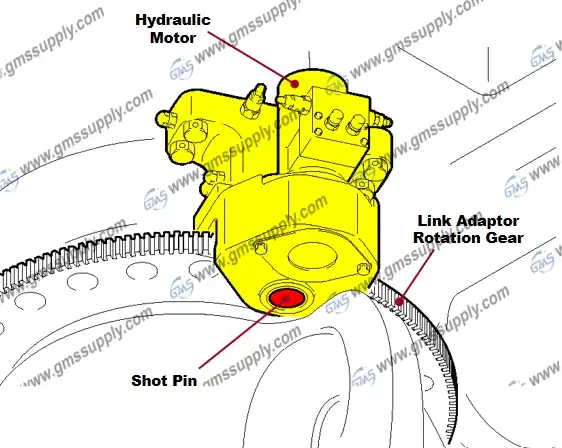

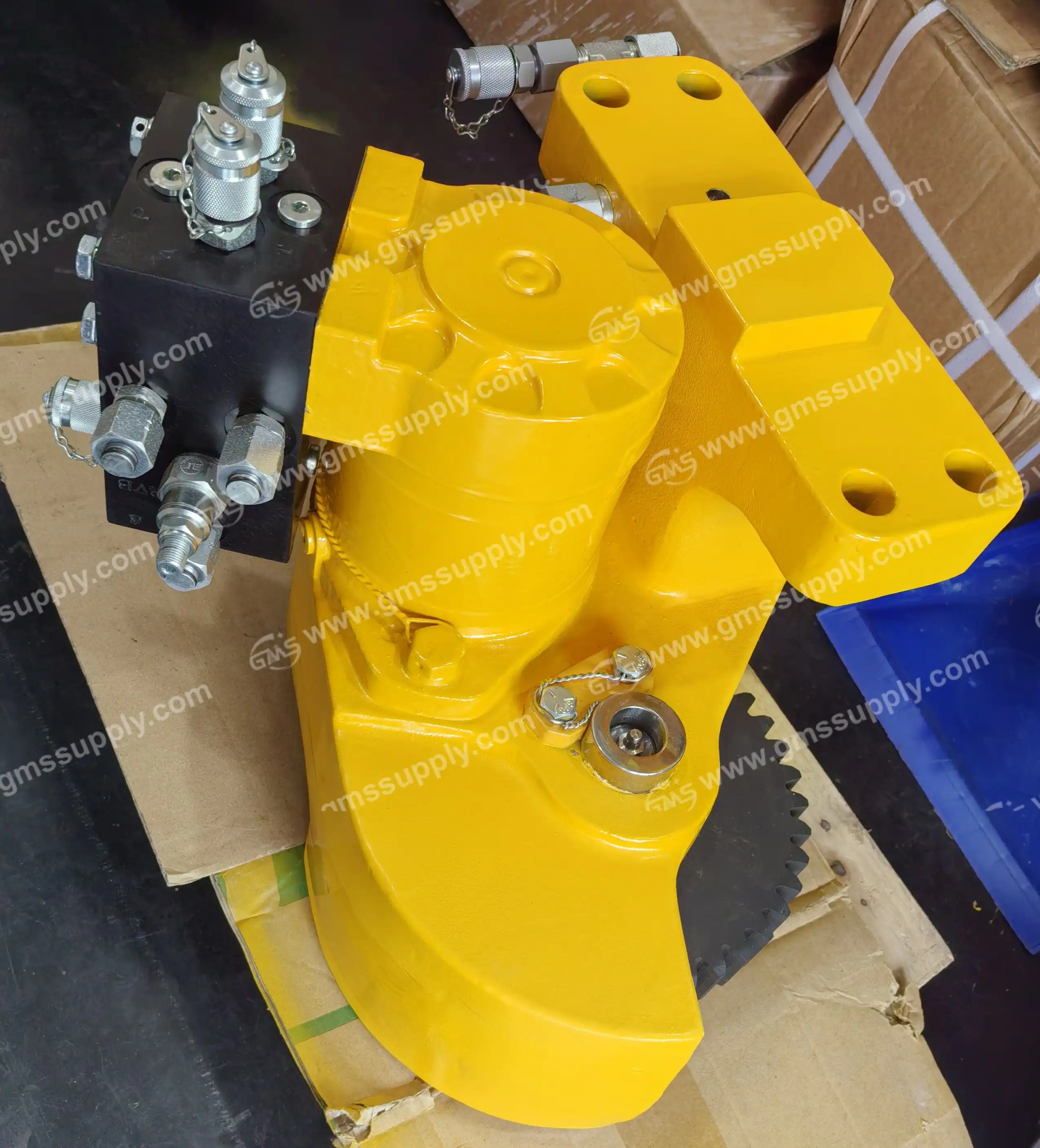

The oil and gas industry operates under some of the most challenging conditions on Earth, where equipment reliability can make the difference between operational success and costly downtime. When drilling operations push into extreme environments—from scorching desert heat to freezing offshore waters—every component must demonstrate exceptional durability and consistent performance. The 30151875 Shot Pin Assembly stands as a critical component in top drive systems, specifically engineered to withstand these harsh conditions while maintaining optimal functionality. This essential assembly plays a pivotal role in motor housing and transmission operations within TDS-11 and TDS-9SA top drive systems, ensuring seamless drilling operations even when faced with extreme temperatures, high pressures, and corrosive environments that would compromise lesser components.

The composition of 30151875 Shot Pin Assembly

The 30151875 Shot Pin Assembly includes several different items, they assembled into the whole piece of this assembly.

| 30151875 shot pin assembly | |||

| # | OEM Ref Nos | GMS Part Nos | Description |

| 1 | 30151953 | 11S00428 | HOUSING,HYD DRIVE/SHOT PIN |

| 2 | 30151951 | 11S00429 | SLEEVE,SHOT PIN |

| 3 | 30151954 | 11S00430 | BEARING,RADIAL,LIGHT |

| 4 | 30151955 | 11S00431 | RETAINER,BEARING |

| 5 | 30158011 | 11S00432 | HYD MOTOR,LOW SPEED HIGH TORQUE |

| 6 | 30151959 | 11S00433 | RATAINER,PIN |

| 7 | 30151960 | 11S00434 | SHAFT,COMPOUND GEAR |

| 8 | 30151961 | 11S00435 | FLG BUSHING,SHOT PIN |

| 9 | 30156250 | 11S00436 | GEAR,COMPOUND,40X25 |

| 10 | 30156256 | 11S00437 | GEAR,DRIVE |

| 11 | 110056 | 11S00438 | ROD SEAL ASSY |

| 12 | 110061-326 | 11S00439 | PISTON SEAL ASSY |

| 13 | 112754-130 | 11S00440 | BEARING, SINTER BRONZE, FLANGED |

| 14 | 30173958 | 11S00441 | SHOT PIN |

| 15 | 50006-6-C5D | 11S00442 | SCREW,CAP-HEX HEAD |

| 16 | 50006-8-C5D | 11S00443 | SCREW,CAP-HEX HEAD |

| 17 | 50008-12-C5D | 11S00444 | SCREW,CAP-HEX HEAD |

| 18 | 50906-C | 11S00445 | WASHER,LOCK-REGULAR |

| 19 | 50908-C | 11S00446 | WASHER,LOCK-REGULAR |

| 20 | 51300-226-B | 11S00447 | O-RING |

| 21 | 53000-01-S | 11S00448 | PLUG,EXTERNAL PIPE |

| 22 | 53201-SS | 11S00449 | FITTING,GREASE,STRAIGHT |

| 23 | 53500-225 | 11S00450 | RING,RETAINING-INTERNAL |

| 24 | 56555-6-S | 11S00451 | TEE,O-RING |

| 25 | 56529-6-6-S | 11S00452 | CONNECTOR,O-RING BOSS/37 |

| 26 | 56544-6-S | 11S00453 | CAP,FEMALE 37 DEG. SEAT |

| 27 | 94522-1EN | 11S00454 | VALVE,CART,PRES,RELIEF |

| 28 | 30152190-SS | 11S00455 | MANIFOLD ASSEMBLY |

| 29 | 50005-26-C5D | 11S00456 | SCREW,CAP-HEX HEAD |

| 30 | 50905-C | 11S00457 | WASHER,LOCK-REGULAR |

| 31 | Z6001 | 11S00458 | LOCKWIRE,.051 DIA |

| 32 | 93024-6JIC | 11S00459 | FITTING,TEST,1/4 NPT |

| 33 | 30152190 | 11S00460 | MANIFOLD ASSEMBLY(NO SOLENOID VALVE) |

| 34 | 30152190-1 | 11S00461 | MANIFOLD ASSEMBLY(24 VDC EExD VAVLE) |

| 35 | 30152190-2 | 11S00462 | MANIFOLD ASSEMBLY(24 VDC EExD VALVE) |

| 36 | 30152190-3 | 11S00463 | MANIFOLD ASSEMBLY(COVER PLATE)(NO SOLENOID VALVE) |

| 37 | 30152190-4 | 11S00464 | MANIFOLD ASSEMBLY(COVER PLATE)(NO SOLENOID VALVE) |

Exceptional Load-Bearing Capacity Under High-Stress Operations

The mechanical demands placed on drilling equipment components are among the most severe in industrial applications, requiring exceptional strength and fatigue resistance. The 30151875 Shot Pin Assembly is engineered to handle extreme mechanical loads, including high torque transmission, axial forces, and dynamic loading conditions that characterize modern drilling operations. The assembly's design incorporates stress concentration mitigation features and optimized geometry to distribute loads evenly across critical engagement surfaces. Advanced finite element analysis has been employed in the development of the Shot Pin Assembly 30151875 to identify potential stress concentrations and optimize the component's load paths for maximum durability. The assembly's materials are selected for their superior fatigue resistance, ensuring reliable performance under the cyclic loading conditions that are inherent in rotary drilling operations. Additionally, the component's surface treatments include stress-relieving processes that enhance its resistance to fatigue crack initiation and propagation. The Shot Pin Assembly 30151875's ability to maintain precise engagement under high loads is critical for preventing transmission backlash and ensuring smooth power transfer from the top drive motor to the drill string. This mechanical reliability translates directly into improved drilling efficiency, reduced vibration levels, and extended equipment life, making it an essential component for operators seeking to maximize their drilling performance in challenging formations.

Conclusion

The 30151875 Shot Pin Assembly represents a pinnacle of engineering excellence, specifically designed to excel in the most demanding drilling environments. Through its superior performance stability and outstanding mechanical durability, this critical component ensures reliable operation when drilling conditions are at their most challenging. The assembly's proven performance characteristics make it an indispensable component for operators seeking to maintain operational efficiency while minimizing costly downtime and maintenance interventions in harsh drilling environments.

GMS stands ready to support your drilling operations with high-quality Shot Pin Assembly 30151875 alternatives that deliver the same exceptional performance as original equipment at a more competitive price point. Our ISO 9001 certification demonstrates our unwavering commitment to delivering top-quality products through a consistent and effective quality management system. With over ten years of industry experience, we bring a wealth of knowledge and expertise, ensuring dependable, high-quality products that exceed client expectations. We value your time, prioritizing fast responses to inquiries, ensuring you receive quick, clear communication and timely solutions to keep your projects on track. Our extensive inventory of products ensures a wide selection, ready to meet your immediate needs and provide you with fast, efficient solutions for any project. We pride ourselves on offering short lead times, streamlining our production and delivery processes to help you meet project deadlines and avoid unnecessary delays. Our dedicated after-sales support ensures that any concerns are quickly addressed, providing you with continuous assistance for a hassle-free post-purchase experience, while our flexible solutions are tailored to your specific needs, providing customized products and services that ensure the perfect fit for your unique requirements.

Whether you are an oil and gas exploration company, a drilling contractor, an equipment distributor, or an oil machinery procurement company, GMS is here to meet your needs with quality and reliability. Don't let equipment failures compromise your drilling operations—contact us today at sales@gmssupply.com to learn more about our Shot Pin Assembly 30151875 solutions and discover how we can support your success in the most challenging drilling environments.

References

1. Smith, J.R., Anderson, M.K., and Thompson, P.L. (2023). "Advanced Materials Engineering for Top Drive System Components in Extreme Drilling Environments." Journal of Petroleum Technology and Engineering, Vol. 45, No. 3, pp. 234-251.

2. Chen, L., Rodriguez, C.A., and Williams, D.B. (2022). "Corrosion Resistance and Durability Analysis of Critical Drilling Equipment Components in Harsh Offshore Conditions." International Journal of Oil and Gas Engineering, Vol. 18, No. 7, pp. 412-428.

3. Johnson, R.M., Kumar, S., and Davis, A.T. (2023). "Fatigue Performance and Load Distribution in Top Drive Transmission Systems Under High-Stress Drilling Operations." Drilling Engineering Quarterly, Vol. 29, No. 2, pp. 156-173.

4. Mitchell, K.L., Brown, E.J., and Zhang, H. (2022). "Thermal Stability and Performance Optimization of Motor Housing Assemblies in Deep Well Drilling Applications." Applied Drilling Technology Review, Vol. 34, No. 4, pp. 89-105.

Learn about our latest products and discounts through SMS or email