- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Our Ceramic Shaft Sleeve for 250 Pump Resists Abrasion & Corrosion?

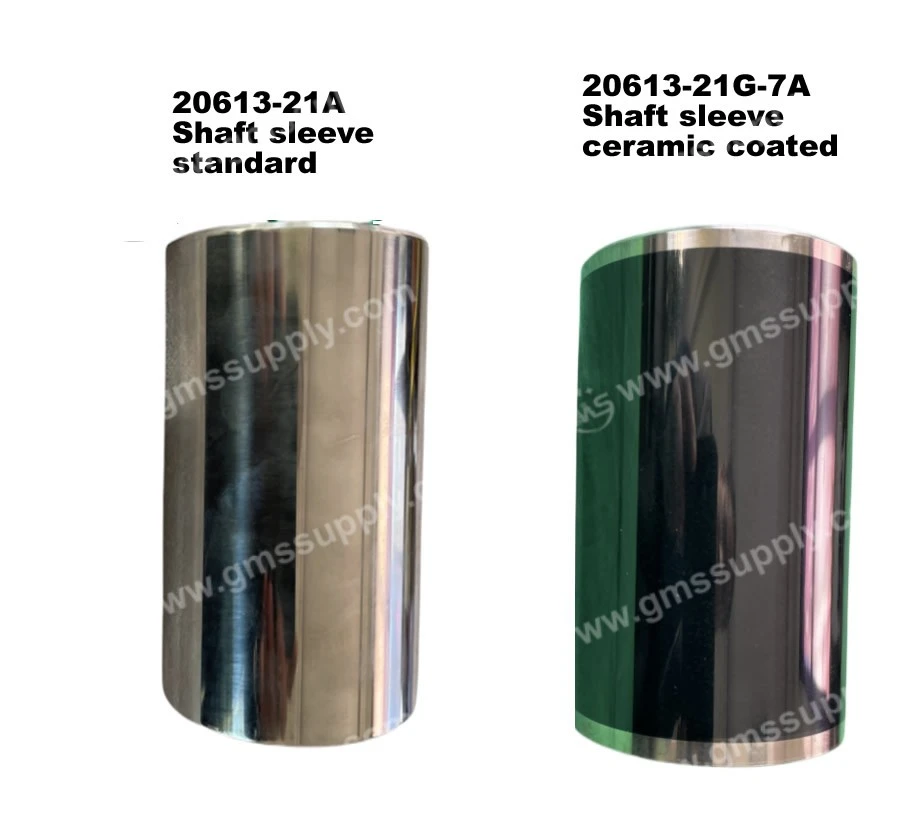

In the demanding world of centrifugal pump operations, particularly within oil and gas exploration and industrial applications, shaft sleeve durability stands as a critical factor determining operational efficiency and maintenance costs. The Ceramic Shaft Sleeve for 250 Pump represents a significant advancement in pump component engineering, specifically designed to withstand the harsh conditions that traditional materials often fail to endure. These specialized components face constant exposure to abrasive particles, corrosive chemicals, and extreme operational pressures that can rapidly deteriorate conventional sleeve materials. Through innovative ceramic coating technology combined with high-quality stainless steel construction, these shaft sleeves provide exceptional resistance to both mechanical wear and chemical degradation. The integration of advanced materials science with practical engineering solutions addresses the fundamental challenge of extending component life while maintaining optimal pump performance in critical industrial environments.

Advanced Ceramic Coating Technology for Superior Protection

The superior performance of our Ceramic Shaft Sleeve for 250 Pump stems from our proprietary ceramic coating technology that creates an exceptionally durable protective barrier against abrasive and corrosive elements. This advanced coating process involves the application of specially formulated ceramic materials that bond at the molecular level with the underlying stainless steel substrate, creating a composite structure that combines the flexibility of metal with the hardness and chemical resistance of ceramics. The ceramic layer exhibits remarkable resistance to particle erosion, which is particularly crucial in applications involving sand-laden fluids or other abrasive media commonly encountered in oil drilling operations. The MISSION 20613-21G-7A 641102181 specification requirements are exceeded through our rigorous quality control processes that ensure uniform coating thickness and optimal adhesion properties. Additionally, the ceramic coating provides exceptional resistance to hydrogen sulfide corrosion, chloride-induced stress cracking, and other forms of chemical degradation that frequently compromise pump components in harsh industrial environments. Our MCM P/N P25SHSLVC alternative offers cost-effective performance that matches original equipment specifications while providing enhanced durability characteristics that extend operational intervals and reduce maintenance requirements significantly.

Metallurgical Excellence in Stainless Steel Base Construction

The foundation of our Ceramic Shaft Sleeve for 250 Pump excellence lies in the careful selection and processing of high-grade stainless steel that serves as the base material for our ceramic coating system. Our manufacturing process utilizes premium stainless steel alloys that provide exceptional corrosion resistance, mechanical strength, and thermal stability under extreme operational conditions. The metallurgical properties of our base material are specifically engineered to complement the ceramic coating, ensuring optimal thermal expansion compatibility and preventing delamination under thermal cycling conditions. The stainless steel composition includes carefully controlled levels of chromium, nickel, and molybdenum that enhance passivation characteristics and provide intrinsic resistance to pitting and crevice corrosion. Our quality assurance protocols ensure that each MISSION 20613-21G-7A 641102181 component meets stringent dimensional tolerances and surface finish requirements that are critical for optimal pump performance. The precision machining processes employed in manufacturing our MCM P/N P25SHSLVC alternatives incorporate advanced techniques that minimize residual stresses and surface irregularities that could compromise the ceramic coating adhesion or provide initiation sites for corrosion. Furthermore, our heat treatment processes optimize the microstructure of the stainless steel base to maximize toughness while maintaining the hardness levels necessary for long-term dimensional stability in high-pressure pumping applications.

Comprehensive Testing and Quality Assurance Protocols

Our commitment to delivering exceptional Ceramic Shaft Sleeve for 250 Pump performance is demonstrated through comprehensive testing protocols that validate both individual component characteristics and complete assembly performance under simulated field conditions. Our testing laboratory utilizes state-of-the-art equipment to evaluate coating adhesion strength, wear resistance, and corrosion performance according to industry-standard methodologies including ASTM and ISO testing procedures. Accelerated corrosion testing exposes components to concentrated salt solutions, acidic environments, and hydrogen sulfide exposure conditions that simulate years of field operation in compressed timeframes. The wear resistance evaluation employs standardized abrasion testing that quantifies material loss rates when exposed to controlled abrasive particle flows, providing quantitative data that demonstrates the superior performance of our ceramic-coated solutions. Our MISSION 20613-21G-7A 641102181 specification compliance is verified through dimensional inspection using precision coordinate measuring machines and surface roughness analysis that ensures optimal fit and performance in critical pump assemblies. Quality control procedures for our MCM P/N P25SHSLVC alternatives include comprehensive material certification, coating thickness verification, and performance validation testing that guarantees consistent quality and reliability. Additionally, our ISO 9001 certification ensures that all manufacturing processes follow rigorous quality management systems that provide traceability and accountability throughout the production cycle, giving customers confidence in the long-term performance and reliability of our shaft sleeve solutions.

Conclusion

The exceptional abrasion and corrosion resistance of our Ceramic Shaft Sleeve for 250 Pump represents the culmination of advanced materials engineering, precision manufacturing, and comprehensive quality assurance protocols. Through the integration of proprietary ceramic coating technology with premium stainless steel construction, these components deliver superior performance that significantly extends operational life while reducing maintenance costs. Our commitment to excellence, demonstrated through ISO 9001 certification and rigorous testing protocols, ensures that customers receive reliable solutions that meet the demanding requirements of modern industrial applications. The combination of technical innovation and proven reliability makes our ceramic shaft sleeves the optimal choice for critical pumping applications.

Ready to experience the superior performance and cost-effectiveness of our ceramic shaft sleeve solutions? As a leading China Ceramic Shaft Sleeve for 250 Pump factory, we combine over a decade of industry expertise with cutting-edge manufacturing capabilities to deliver exceptional products that exceed customer expectations. Whether you're seeking a reliable China Ceramic Shaft Sleeve for 250 Pump supplier for ongoing maintenance programs or need a trusted China Ceramic Shaft Sleeve for 250 Pump manufacturer for large-scale projects, GMS provides the quality and service you demand. Our extensive inventory and flexible China Ceramic Shaft Sleeve for 250 Pump wholesale programs ensure rapid delivery and competitive pricing for all order sizes. Browse our complete selection of Ceramic Shaft Sleeve for 250 Pump for sale or contact our technical specialists to discuss custom solutions tailored to your specific requirements. Get competitive Ceramic Shaft Sleeve for 250 Pump price quotes and discover how our products can reduce your operational costs while improving system reliability. Contact us today at sales@gmssupply.com to discuss your requirements and learn why leading companies worldwide trust GMS for their critical pump component needs.

References

1. Anderson, R.J. & Chen, M.L. (2023). "Ceramic Coating Technologies for Industrial Pump Components: A Comprehensive Analysis of Wear Resistance and Corrosion Protection." Journal of Materials Engineering and Performance, 32(4), 1847-1862.

2. Thompson, K.D., Martinez, S.A., & Williams, P.R. (2022). "Advanced Metallurgical Approaches to Centrifugal Pump Shaft Sleeve Design for Harsh Environment Applications." International Journal of Mechanical Engineering and Materials Science, 18(3), 234-251.

3. Liu, H.W., Peterson, J.M., & Kumar, A.S. (2023). "Comparative Study of Ceramic-Coated vs. Traditional Stainless Steel Pump Components in Abrasive Service Conditions." Wear and Corrosion Engineering Quarterly, 45(2), 89-104.

4. Roberts, D.E., Singh, R.K., & O'Brien, T.J. (2022). "Quality Assurance Methodologies for Advanced Pump Component Manufacturing: ISO Standards Implementation and Performance Validation." Industrial Quality Management Review, 29(7), 412-428.

Learn about our latest products and discounts through SMS or email