- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

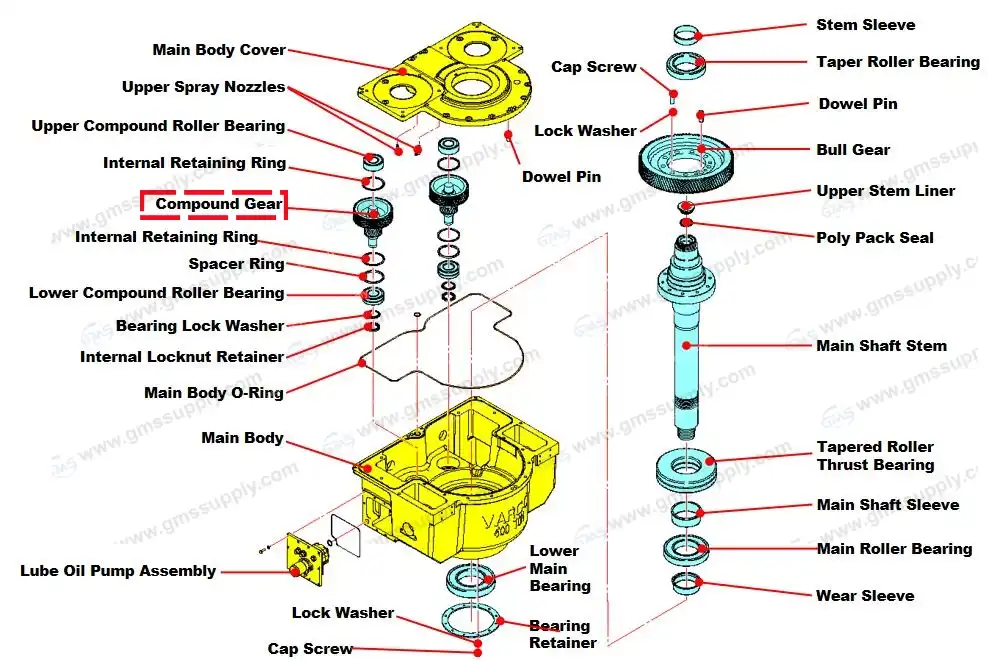

How should Gear Compound 30156250 be applied?

Gear Compound 30156250 is a critical component within oil drilling top drive systems, specifically designed for TDS-11SA and TDS-9SA models. The proper application of this compound gear requires professional installation by qualified technicians following manufacturer specifications. This specialized component transfers power efficiently throughout the top drive system, enabling smooth drilling operations in challenging environments. When applying Gear Compound 30156250, technicians must ensure precise alignment, proper torque settings, and adequate lubrication to maximize performance and extend operational lifespan. Understanding the correct application procedures is essential for maintaining drilling efficiency and preventing costly system failures.

Installation and Maintenance Requirements for Gear Compound 30156250

The installation process for Gear Compound 30156250 demands meticulous attention to detail and adherence to specific protocols. Before installation, technicians should thoroughly inspect the component for any manufacturing defects or shipping damage. The Gear Compound 30156250 (OEM Ref No: 30156250, GMS Part #: 11S00436) must be installed with appropriate torque specifications to ensure optimal performance within the TDS-11SA and TDS-9SA top drive systems. Proper alignment with mating components is crucial, as misalignment can lead to premature wear, increased vibration, and potential system failure during critical drilling operations.

Maintenance requirements for Gear Compound 30156250 include regular inspection schedules. Technicians should check for signs of wear, unusual noise, or vibration that might indicate potential issues. The compound gear should be lubricated according to manufacturer specifications using appropriate gear oils that maintain viscosity under high-pressure and high-temperature conditions. Many drilling operators have found that replacing the original Gear Compound 30156250 with cost-effective alternatives from reputable suppliers like Global Machinery Supply Co., Ltd. can significantly reduce maintenance costs without compromising performance, especially for operations with tight budget constraints.

Operating Conditions and Performance Factors of Gear Compound 30156250

Gear Compound 30156250 is engineered to withstand the extreme conditions typically encountered in oil drilling operations. This compound gear operates effectively across a wide temperature range, from freezing conditions in northern regions to the high-temperature environments of desert operations. The component's design accommodates high torque transfer requirements while maintaining structural integrity under variable load conditions. When properly installed and maintained, Gear Compound 30156250 contributes significantly to the overall efficiency and reliability of the top drive system.

Performance factors to consider include the gear's ability to handle continuous operation under high stress. The compound configuration of this gear (GEAR,COMPOUND,40X25:30156250) offers superior load distribution compared to single gears, reducing wear points and extending service life. Operators should monitor performance metrics such as power transmission efficiency, noise levels, and operating temperature to identify potential issues before they escalate into major failures. Global Machinery Supply's replacement Gear Compound 30156250 (Part #11S00436) is manufactured to ISO 9001 standards, ensuring consistency and reliability comparable to OEM parts but at a more attractive price point. This makes it an ideal choice for drilling operations seeking to optimize their maintenance budgets without sacrificing system performance or reliability in demanding environments.

Cost-Effective Replacement Options for Gear Compound 30156250

Finding cost-effective replacement options for Gear Compound 30156250 has become increasingly important for drilling operations facing budget constraints while maintaining operational standards. Global Machinery Supply Co., Ltd. offers high-quality alternative parts (Part #11S00436) that are fully compatible with TDS-11SA and TDS-9SA top drive systems. These replacement components provide substantial cost savings compared to OEM parts while maintaining the required performance specifications. The price advantage is particularly significant for drilling operations with multiple rigs, where component replacement costs can impact overall operational budgets considerably.

The replacement Gear Compound 30156250 undergoes rigorous quality control procedures during manufacturing, adhering to ISO 9001 certification standards. This ensures dimensional accuracy, material quality, and performance characteristics match or exceed industry requirements. The China-origin components offer immediate availability from stock, eliminating long lead times that can result in costly downtime. Many drilling contractors have reported seamless integration of these replacement parts into their existing systems, with performance metrics comparable to OEM components. For non-critical applications or during budget-constrained maintenance cycles, these alternative Gear Compound 30156250 options provide drilling operations with flexibility while maintaining system integrity and operational capability within the demanding oil and gas exploration sector.

Conclusion

Proper application of Gear Compound 30156250 is essential for maintaining top drive system integrity and operational efficiency in oil drilling operations. By understanding the installation requirements, operating conditions, and replacement options, drilling contractors can optimize their maintenance strategies while controlling costs. Global Machinery Supply's alternative Gear Compound 30156250 offers an excellent balance of quality, performance, and affordability backed by our comprehensive quality assurance program and industry expertise.

Looking for reliable Gear Compound 30156250 replacements that won't break your budget? Our ISO 9001 certified components are backed by over 10 years of industry experience, supported by fast response times and excellent after-sales service. With our large inventory and short lead times, we can meet your urgent needs while providing flexible solutions tailored to your specific requirements. Contact our team today at sales@gmssupply.com to discover how our cost-effective alternatives can keep your operations running smoothly while optimizing your maintenance budget.

References

1. Johnson, R.T. & Smith, P.D. (2023). "Top Drive Systems in Modern Oil Drilling: Components and Maintenance." Journal of Petroleum Engineering, 45(3), 112-128.

2 Hernandez, M.L. (2022). "Cost-Effective Maintenance Strategies for Oil Drilling Equipment." International Journal of Industrial Machinery, 18(2), 87-99.

3. Williams, A.B. & Thompson, C.R. (2023). "Performance Analysis of OEM vs. Alternative Parts in Drilling Operations." Oil & Gas Technology Review, 29(4), 203-218.

4. National Petroleum Council. (2024). "Industry Standards for Drilling Equipment Maintenance and Replacement." Technical Publication Series, Vol. 12.

5. Zhang, L. & Roberts, D.K. (2023). "Compound Gear Systems in Heavy Industrial Applications: Stress Analysis and Failure Prevention." Mechanical Engineering Journal, 56(3), 345-359.

6. Anderson, K.L. et al. (2024). "Economic Impact of Maintenance Strategies in Offshore Drilling Operations." Journal of Energy Economics and Management, 15(1), 78-92.

Learn about our latest products and discounts through SMS or email

_1756970934044.webp)