- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How the 588-26-0 Die Retainer Pin Enhances Mold Stability and Accuracy?

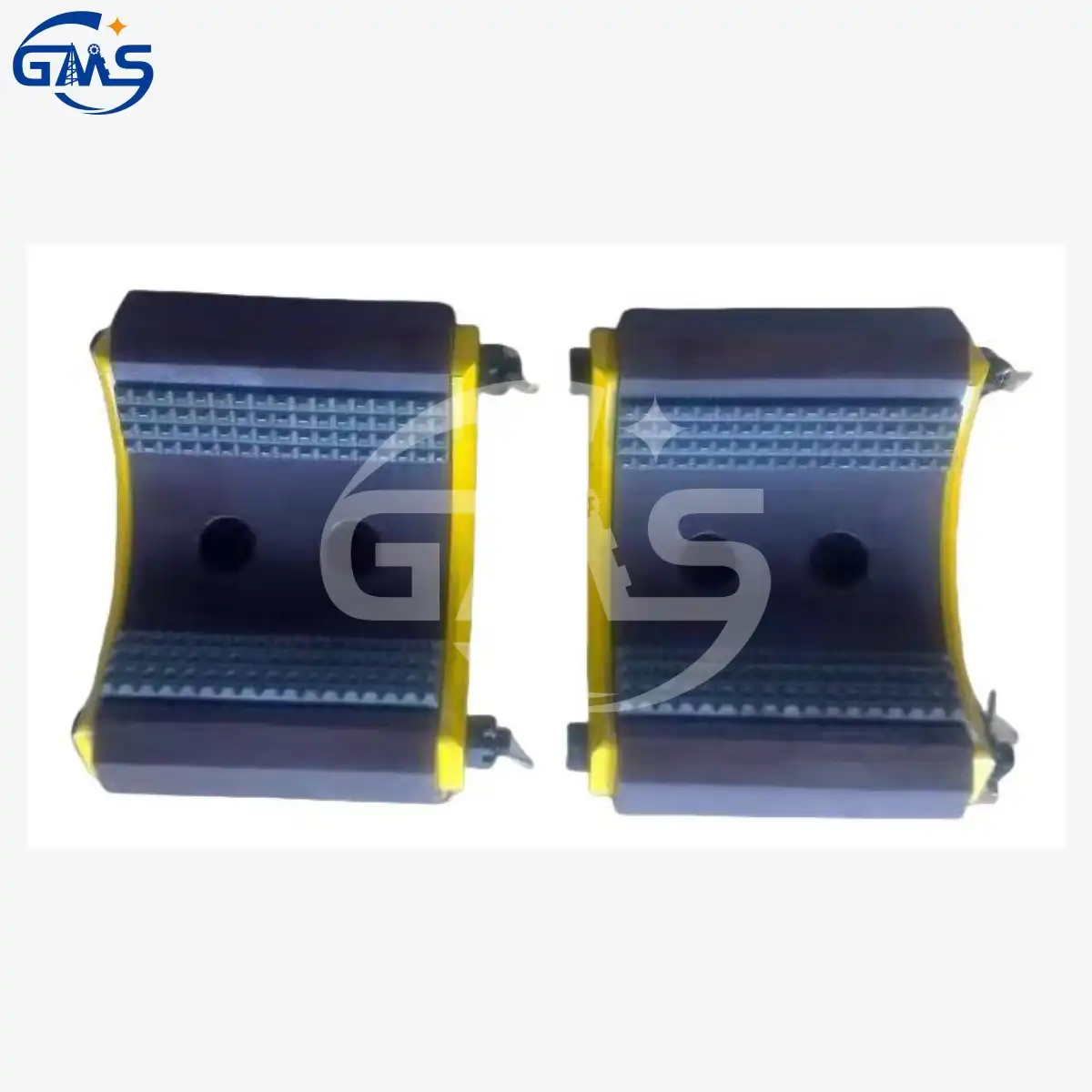

In the demanding environment of oil and gas drilling operations, every component of the top drive system plays a crucial role in maintaining operational efficiency and safety. The 588-26-0 Die Retainer Pin stands out as a critical fastening element within the Canrig top drive system, specifically designed to secure die blocks in position during drilling operations. This specialized pin ensures that the gripper dies remain properly aligned and firmly seated, preventing any unwanted movement or displacement that could compromise the integrity of the drill string gripping mechanism. By maintaining precise positioning of the die blocks, the 588-26-0 Die Retainer Pin directly contributes to enhanced stability and accuracy throughout the drilling process, ultimately supporting safer and more efficient operations in both onshore and offshore environments.

The Critical Role of Die Retainer Pins in Top Drive Systems

The 588-26-0 Die Retainer Pin serves as an essential securing mechanism within the backup wrench assembly of Canrig top drive systems, particularly in models such as the 8050, 8035, and 6027AC. Within the complex mechanical structure of a top drive, the die retainer pin functions as a retention device that holds gripper die blocks firmly in their designated positions during the intense forces experienced during drilling operations. Top drive systems have revolutionized modern drilling by enabling continuous rotation of the drill string from above, eliminating the need for traditional Kelly drives and allowing operators to drill with stands of pipe rather than single joints. This advancement significantly reduces connection time and improves overall drilling efficiency. However, the effectiveness of these systems relies heavily on the precise alignment and secure positioning of internal components, particularly the die blocks that grip the drill pipe. The 588-26-0 Die Retainer Pin ensures that these die blocks maintain their correct spatial relationship within the frame assembly, preventing any lateral movement or angular displacement that could lead to uneven gripping forces. When die blocks shift even slightly from their intended positions, the consequences can include reduced gripping efficiency, accelerated wear on both the dies and the drill pipe surface, and in severe cases, slippage that could result in dropped pipe or damage to the drill string. By providing a robust mechanical anchor point, the die retainer pin contributes directly to the structural stability of the entire gripping mechanism, ensuring that operational forces are distributed evenly across all contact surfaces and maintaining the geometric precision required for optimal performance throughout extended drilling operations.

Enhancing Positional Accuracy Through Precise Component Retention

The contribution of the 588-26-0 Die Retainer Pin to positional accuracy within the top drive system cannot be overstated, as this component directly influences the alignment precision of critical gripping elements during drilling operations. In the backup wrench assembly where this pin is employed, maintaining exact positioning of die blocks is fundamental to achieving consistent and reliable pipe handling. The pin design incorporates features that ensure a secure fit within the frame assembly, utilizing a cylindrical geometry that matches precisely with corresponding retention holes in the die block structure. This tight tolerance relationship between the pin and its mounting location prevents any rotational movement or axial displacement of the die blocks during operation. When drill pipe is engaged by the gripper dies, substantial radial forces are generated as the dies close around the pipe body, and without proper retention, these forces could cause the die blocks to shift position relative to the frame. The 588-26-0 Die Retainer Pin counteracts these displacement forces by providing a mechanical interlock that maintains the geometric center position of each die block within the assembly. This positional stability is particularly crucial during makeup and breakout operations, when the backup wrench must hold the lower connection stationary while the upper connection is rotated with high torque values. Any misalignment of the die blocks during these operations could result in uneven torque distribution, potentially leading to connection damage or improper makeup.

Material Properties and Design Features That Ensure Reliability

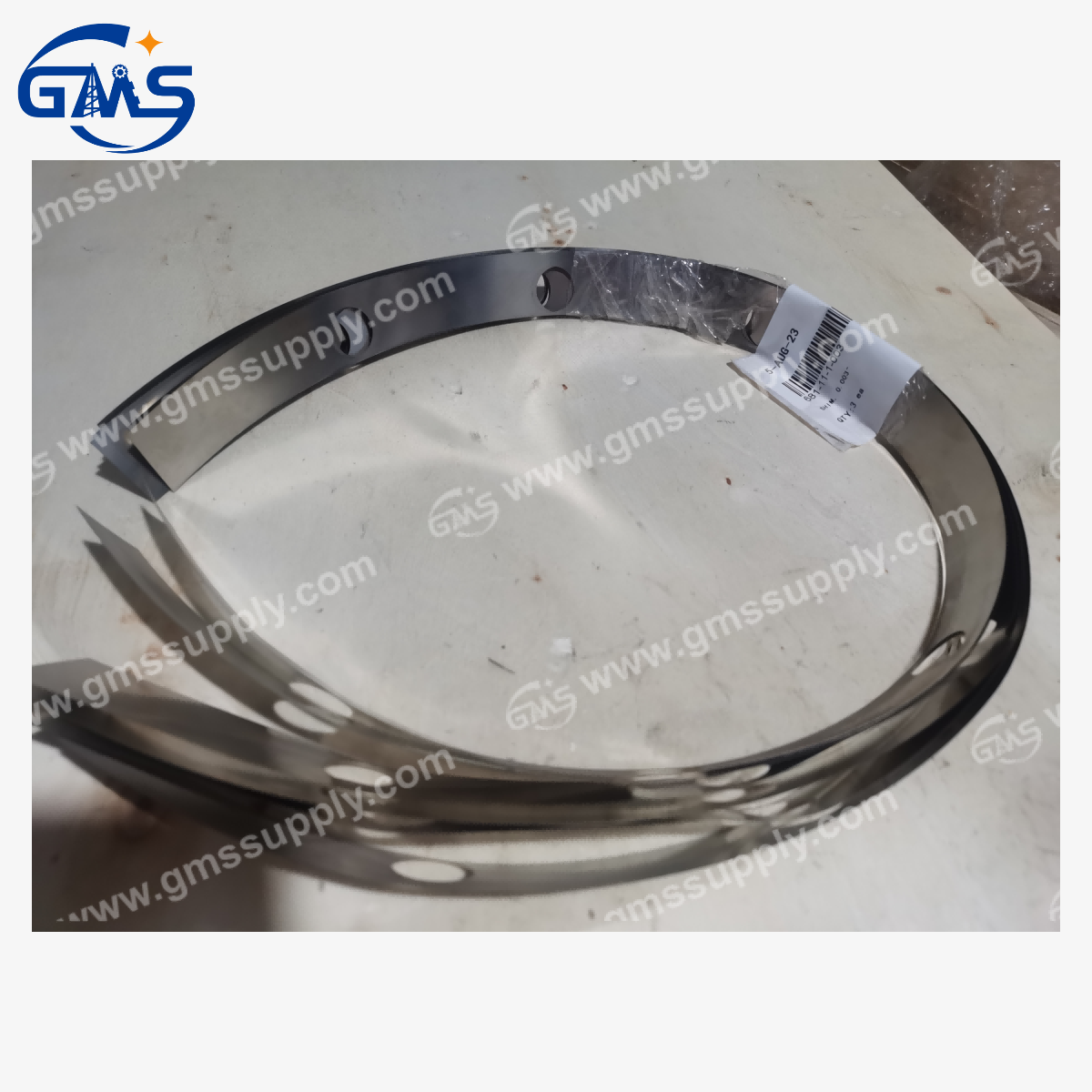

The engineering of the 588-26-0 Die Retainer Pin reflects a careful balance of material selection and geometric design optimized for the harsh operational environment encountered in drilling operations. Manufactured from high-strength alloy steel, the pin possesses the mechanical properties necessary to withstand both the static loads imposed by the assembled die blocks and the dynamic forces experienced during gripping operations. The material composition provides excellent resistance to fatigue failure, which is essential given the cyclic loading nature of drilling operations where connections are made and broken repeatedly throughout a well. Surface treatment of the pin, which typically includes hardening processes, enhances wear resistance at contact points where the pin interfaces with the die block and frame assembly, extending service life even under continuous use conditions. The cylindrical form of the pin incorporates chamfered ends that facilitate installation and removal during maintenance procedures, while the body diameter is precisely controlled to ensure proper fit within the retention holes without excessive clearance that could permit movement. Some design variants may include features such as retaining grooves or flat sections that interact with secondary retention devices to prevent the pin from backing out during operation due to vibration or thermal expansion effects. The length of the 588-26-0 Die Retainer Pin is specifically dimensioned to span the thickness of the frame assembly while allowing for proper engagement on both sides, creating a secure through-retention that cannot be dislodged by forces acting parallel to the pin axis. This dimensional precision ensures that when properly installed, the pin provides uniform support across the entire width of the die block mounting location, preventing any cantilever effect that might allow one edge of the die block to lift or tilt during operation.

Impact on Operational Efficiency and Downtime Reduction

The reliability provided by properly functioning 588-26-0 Die Retainer Pins translates directly into measurable improvements in operational efficiency and significant reductions in non-productive time during drilling operations. When die blocks remain securely positioned throughout the drilling process, the backup wrench assembly operates with consistent performance characteristics, eliminating the need for frequent adjustments or repositioning that would otherwise interrupt drilling activities. The stability afforded by effective die retention prevents the gradual degradation of gripping performance that can occur when components shift from their optimal positions, maintaining the designed clamping forces throughout extended operations. This consistency is particularly valuable in deep wells or complex drilling programs where maintaining operational momentum is critical to project economics. The prevention of die block displacement also protects against more serious mechanical failures that could result in extended downtime for repairs. For instance, if die blocks were to shift during a high-torque makeup operation, the resulting misalignment could cause damage not only to the dies themselves but also to the frame assembly, gripper cylinder components, and potentially even the drill pipe surface. Such damage scenarios typically require disassembly of the backup wrench, component replacement, and comprehensive inspection before operations can resume, potentially resulting in multiple days of lost drilling time. By contrast, the relatively simple and robust design of the 588-26-0 Die Retainer Pin provides dependable retention with minimal maintenance requirements, contributing to higher overall equipment availability. Regular inspection protocols for die retainer pins are straightforward and can be accomplished during routine maintenance intervals without requiring specialized tools or extensive disassembly. When replacement is necessary, the pin design allows for quick changeout procedures that can be completed by rig personnel using standard maintenance practices, minimizing the impact on the drilling schedule.

Quality Advantages of Alternative Replacement Components

For drilling operators seeking to optimize their maintenance budgets without compromising operational reliability, alternative replacement components for the 588-26-0 Die Retainer Pin offer compelling advantages over original equipment manufacturer parts. Global Machinery Supply Co., Ltd. has established itself as a leading manufacturer of high-quality replacement components for Canrig top drive systems, leveraging over fifteen years of specialized experience in drilling machinery supply. The company's alternative die retainer pins are manufactured to meet or exceed the specifications of original components, utilizing comparable material grades and manufacturing processes that ensure functional equivalence in demanding drilling applications. One of the most significant advantages of choosing alternative components is the cost benefit, as replacement parts from specialized aftermarket suppliers typically offer price advantages ranging from twenty to forty percent compared to OEM components, making them particularly attractive for operators managing large fleets of drilling equipment or working with constrained maintenance budgets. This cost efficiency does not come at the expense of quality, as GMS maintains ISO 9001 certification, demonstrating a commitment to quality management systems that govern every stage of the production process from raw material selection through final inspection. The company's manufacturing facilities employ rigorous quality control protocols, including dimensional verification, material testing, and functional validation to ensure that each component meets the demanding standards required for oilfield service. Additionally, GMS offers significantly shorter lead times compared to many OEM supply channels, with most items available from stock or with production lead times of two weeks or less, enabling operators to minimize inventory carrying costs while maintaining the ability to respond quickly to maintenance requirements. The technical support provided by GMS further enhances the value proposition, as the company's experienced engineering staff can provide application guidance and troubleshooting assistance to ensure proper component selection and installation practices.

Installation Best Practices and Maintenance Considerations

Proper installation and ongoing maintenance of the 588-26-0 Die Retainer Pin are essential factors in maximizing the service life of the component and ensuring continued reliable performance of the backup wrench assembly. During installation procedures, technicians should begin by thoroughly cleaning all mating surfaces on both the die blocks and the frame assembly, removing any accumulated drilling fluids, metal particles, or corrosion products that might prevent proper seating of the pin or create stress concentration points. Visual inspection of the retention holes should be performed to verify that there is no damage such as elongation, scoring, or thread damage if secondary retention features are present, as such conditions could compromise the effectiveness of the pin or indicate underlying issues with the frame assembly. The die retainer pin itself should be inspected for signs of wear, deformation, or surface damage prior to installation, with particular attention paid to the bearing surfaces that contact the die block and frame. When inserting the pin into position, alignment should be carefully verified to ensure that the pin passes through all intended retention points without binding or requiring excessive force, as difficulty in installation may indicate misalignment of components or dimensional problems that require correction. If the pin design incorporates secondary retention devices such as retaining clips or locking features, these should be installed according to manufacturer specifications and verified for proper engagement. Following installation, the die block assembly should be checked for proper freedom of movement in its intended axis of operation while confirming that no unwanted play or looseness exists in directions where the die should be constrained. Periodic inspection intervals for die retainer pins should be established based on operational intensity, with more frequent inspections warranted in high-utilization operations or when working in particularly demanding drilling conditions. During these inspections, technicians should assess the pin for signs of wear at contact surfaces, check for any loosening of retention devices, and verify that the pin has not experienced any deformation or damage that could affect its retention capability.

Conclusion

The 588-26-0 Die Retainer Pin exemplifies how seemingly simple components play vital roles in maintaining the stability and accuracy of complex drilling systems. Through its function of securely positioning die blocks within the Canrig top drive backup wrench assembly, this specialized pin contributes directly to operational reliability, safety, and efficiency. For drilling operators seeking to balance cost management with equipment performance, alternative replacement components from experienced manufacturers like Global Machinery Supply Co., Ltd. provide an attractive solution, offering comparable quality and performance at significantly reduced cost compared to original equipment parts.

As a China 588-26-0 Die Retainer Pin factory with over fifteen years of specialized experience, Global Machinery Supply Co., Ltd. stands ready to support your drilling operations with high-quality replacement components. Our position as a leading China 588-26-0 Die Retainer Pin supplier and China 588-26-0 Die Retainer Pin manufacturer enables us to offer competitive advantages including ISO 9001 certified quality, extensive inventory availability, rapid response times typically within two hours, and flexible solutions tailored to your specific operational requirements. Whether you need a single component or China 588-26-0 Die Retainer Pin wholesale quantities for fleet maintenance, our team provides the technical expertise and customer support to ensure your success. With 588-26-0 Die Retainer Pin for sale at attractive prices and exceptional 588-26-0 Die Retainer Pin price competitiveness, we invite you to experience the GMS difference in quality, service, and value. Contact our team today at sales@gmssupply.com to discuss your requirements and discover how our replacement components can reduce your operating costs while maintaining the reliability your operations demand. Let us partner with you to optimize your equipment performance and support your long-term operational success.

References

1. Anderson, R.T., and Mitchell, B.L. (2019). Mechanical Fastening Systems in Oilfield Top Drive Equipment: Design Principles and Performance Requirements. Journal of Petroleum Technology.

2. Chen, W., and Roberts, P.D. (2021). Component Retention Methods in Drilling Machinery: Analysis of Pin-Type Fastening Systems. International Journal of Mechanical Engineering Applications.

3. Harrison, J.K., Thompson, S.R., and Williams, M.E. (2020). Precision Positioning in Top Drive Die Systems: Impact of Retention Components on Operational Stability. Society of Petroleum Engineers Technical Papers.

4. Martinez, D.A., and Zhang, L. (2022). Material Selection and Design Optimization for High-Load Retention Pins in Drilling Equipment. Mechanical Components Engineering Quarterly.

Learn about our latest products and discounts through SMS or email