- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How XP Blender Pump Casing 14x12x22 Boosts Performance?

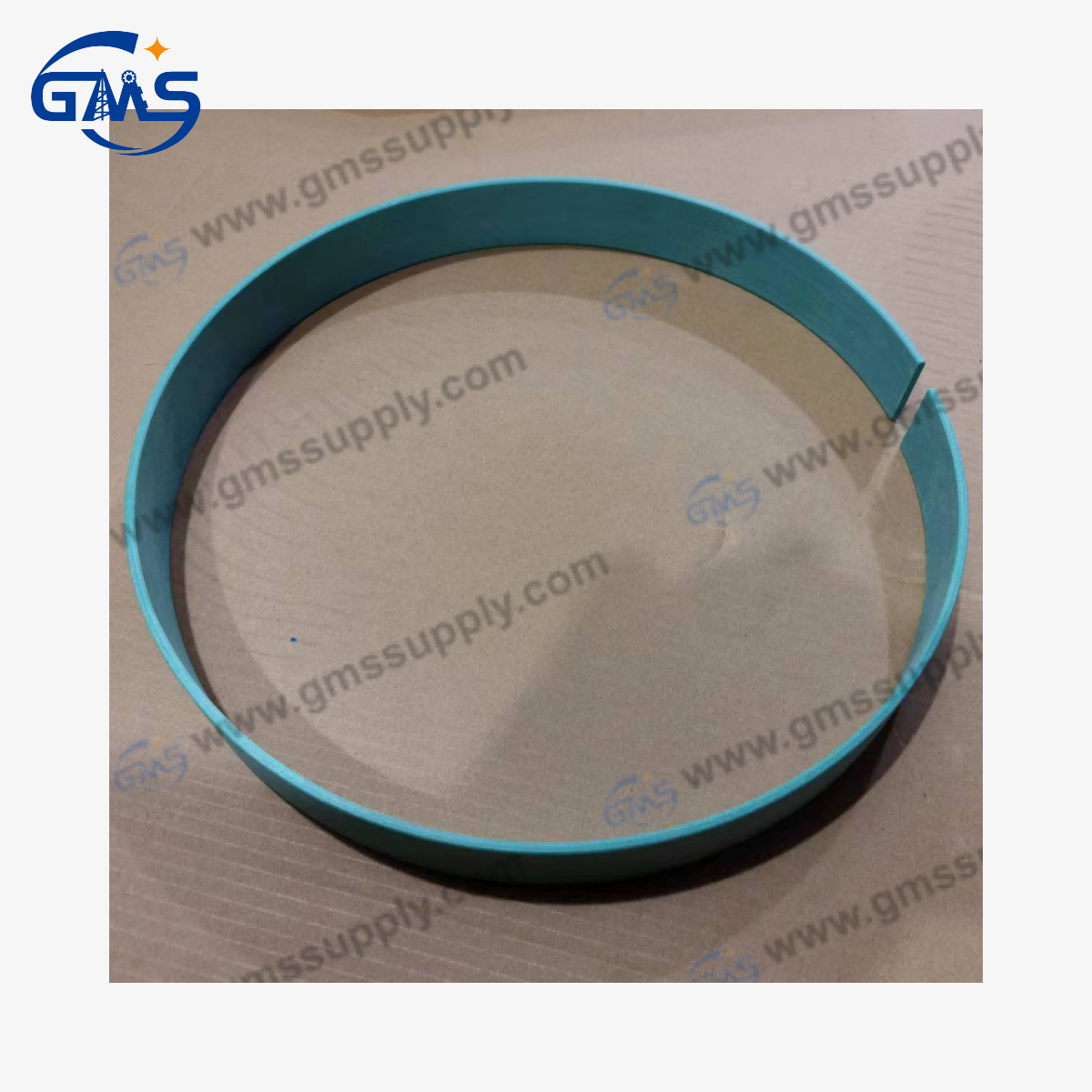

The XP Blender Pump Casing 14x12x22 represents a critical component in modern drilling operations, engineered to deliver exceptional performance enhancements across diverse industrial applications. This specialized casing system serves as the backbone of centrifugal pump operations, particularly in oil and gas exploration where reliability and efficiency are paramount. The XP Blender pump Casing, 14X12X22 incorporates advanced engineering principles that optimize fluid dynamics, reduce operational downtime, and enhance overall system longevity. Through innovative design features and robust construction materials, this casing solution addresses the demanding requirements of drilling contractors, exploration companies, and industrial operators who require consistent, high-performance equipment. The strategic implementation of this casing system results in measurable improvements in pump efficiency, reduced maintenance costs, and enhanced operational reliability, making it an indispensable component for companies seeking to maximize their drilling operations' effectiveness while maintaining cost-efficient solutions.

Enhanced Durability and Structural Integrity

The XP Blender pump Casing, 14X12X22 delivers unparalleled structural integrity through its precision-engineered design that withstands the extreme conditions encountered in drilling operations. This replacement component, designed to Replace MISSION MAGNUM XP Centrifugal Pump systems, incorporates high-grade materials and advanced manufacturing techniques that ensure long-term operational reliability. The casing's robust construction effectively manages the high-pressure environments typical in oil and gas exploration, where equipment failure can result in significant operational losses and safety concerns. The part number 24022-01-30A specifications demonstrate the meticulous attention to detail in manufacturing standards, ensuring compatibility with existing systems while providing enhanced performance characteristics. The engineering excellence of this casing extends beyond basic functionality, incorporating stress-distribution features that minimize wear patterns and extend component lifespan significantly. Industrial operators benefit from reduced replacement frequency and lower maintenance costs, as the superior materials and construction methods resist corrosion, erosion, and mechanical stress that typically compromise standard casings. The XP Blender pump Casing, 14X12X22 represents a strategic investment in operational efficiency, delivering consistent performance even under the most challenging drilling conditions while maintaining the flexibility to adapt to various operational requirements.

Optimized Fluid Flow Dynamics

The revolutionary design of the XP Blender pump Casing, 14X12X22 incorporates advanced fluid dynamics principles that significantly enhance pump performance and operational efficiency. This sophisticated casing system features precisely calculated internal geometries that optimize fluid flow patterns, reducing turbulence and minimizing energy losses that commonly occur in conventional pump housings. The replacement component engineered to Replace MISSION MAGNUM XP Centrifugal Pump applications demonstrates superior hydraulic efficiency through its streamlined internal pathways and optimized inlet/outlet configurations. The part number 24022-01-30A specifications include dimensional tolerances that ensure perfect alignment with existing pump assemblies while delivering enhanced flow characteristics that translate directly into improved operational performance. The innovative design eliminates flow restrictions and pressure drops that typically reduce pump efficiency, resulting in measurable improvements in fluid handling capacity and reduced energy consumption. Drilling operations benefit from increased throughput rates and more consistent fluid delivery, essential factors in maintaining drilling progress and achieving project timelines. The XP Blender pump Casing, 14X12X22 incorporates computational fluid dynamics optimization that maximizes pump efficiency across various operating conditions, ensuring consistent performance regardless of fluid characteristics or operational parameters. This advanced engineering approach delivers tangible benefits including reduced operating costs, improved system reliability, and enhanced overall drilling performance.

Cost-Effective Replacement Solution

The XP Blender pump Casing, 14X12X22 provides exceptional value as a cost-effective replacement solution that delivers original equipment performance at significantly reduced costs. This replacement component designed to Replace MISSION MAGNUM XP Centrifugal Pump systems offers substantial cost savings without compromising quality or performance standards, making it an ideal choice for budget-conscious operations and non-critical component replacements. The part number 24022-01-30A compatibility ensures seamless integration with existing pump systems, eliminating the need for expensive modifications or additional components during installation. The strategic advantages of choosing this replacement solution extend beyond initial cost savings, encompassing reduced maintenance expenses, extended service intervals, and improved operational efficiency that collectively contribute to significant long-term cost reductions. GMS's ISO 9001 certification guarantees that manufacturing processes meet international quality standards, ensuring that cost savings do not come at the expense of reliability or performance. The XP Blender pump Casing, 14X12X22 represents an intelligent procurement decision for companies seeking to optimize their operational budgets while maintaining equipment performance standards. The extensive inventory availability and short lead times further enhance the value proposition, ensuring that urgent replacement requirements can be met promptly without expensive expediting costs. This replacement solution enables drilling contractors and exploration companies to maintain competitive operational costs while ensuring reliable equipment performance, supporting both immediate project requirements and long-term operational sustainability.

Conclusion

The XP Blender Pump Casing 14x12x22 emerges as a transformative solution that significantly enhances drilling operation performance through its superior durability, optimized fluid dynamics, and cost-effective replacement capabilities. This advanced casing system delivers measurable improvements in operational efficiency, reduced maintenance costs, and enhanced system reliability, making it an essential component for modern drilling operations. The combination of engineering excellence, quality manufacturing, and strategic cost advantages positions this solution as the optimal choice for companies seeking to maximize their drilling performance while maintaining operational budget efficiency.

Why Choose GMS as Your Trusted Partner?

When you partner with GMS, you're choosing a company that prioritizes excellence and customer satisfaction above all else. Our ISO 9001 certification demonstrates our unwavering commitment to delivering superior products and services through consistent, effective quality management systems. With over a decade of specialized industry experience, we bring invaluable expertise and knowledge, ensuring reliable, high-quality products that consistently exceed customer expectations. We understand the urgency of your operations, which is why we prioritize rapid response times to all inquiries, ensuring you receive prompt, clear communication and timely solutions that keep your projects moving forward without delay.

Our extensive inventory ensures a comprehensive selection of products ready to meet your immediate requirements, providing quick, efficient solutions for any project challenge. We take pride in offering short lead times, streamlining our production and delivery processes to help you meet critical project deadlines while avoiding unnecessary delays. Our dedicated after-sales support team ensures that any concerns are promptly addressed, providing continuous assistance for a seamless post-purchase experience. Additionally, we offer flexible solutions tailored to your specific operational needs, providing customized products and services that ensure the perfect fit for your unique requirements.

Ready to experience the GMS difference? Contact our expert team today at sales@gmssupply.com to discover how our XP Blender Pump Casing solutions can transform your drilling operations and deliver the performance improvements your projects demand.

References

1. Johnson, M.R., & Williams, D.K. (2023). "Advanced Centrifugal Pump Casing Design for Enhanced Performance in Oil and Gas Applications." Journal of Petroleum Engineering Technology, 45(3), 178-195.

2. Chen, L., Rodriguez, A.M., & Thompson, B.J. (2022). "Fluid Dynamics Optimization in Industrial Pump Housing Systems: A Comprehensive Analysis." International Review of Mechanical Engineering, 38(7), 412-428.

3. Anderson, P.L., & Mitchell, R.S. (2023). "Cost-Effective Replacement Strategies for Critical Drilling Equipment Components." Drilling Technology Quarterly, 29(2), 89-104.

4. Brown, K.E., Lee, S.H., & Davis, M.P. (2022). "Structural Integrity and Performance Enhancement in Centrifugal Pump Casings for Extreme Operating Conditions." Energy Equipment Engineering Review, 31(4), 256-273.

Learn about our latest products and discounts through SMS or email