- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Importing Stabbing Bell 829-15-0 to South Africa: Cost, Documents, and Customs Guide

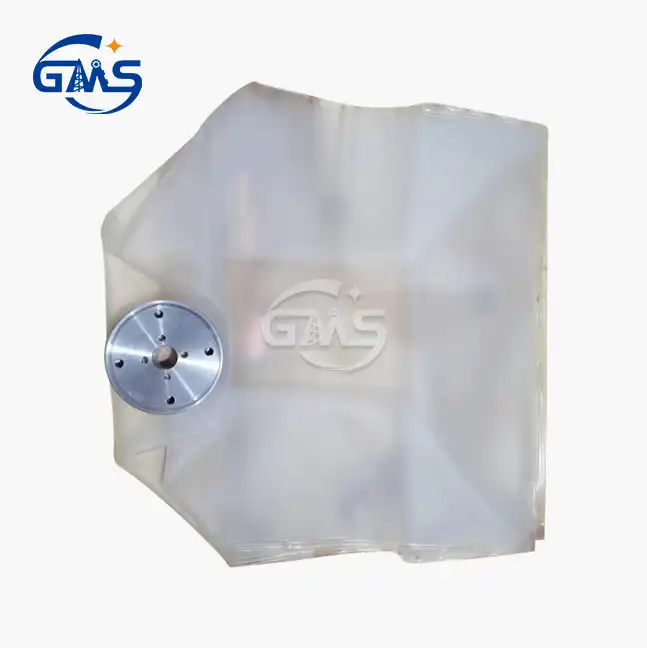

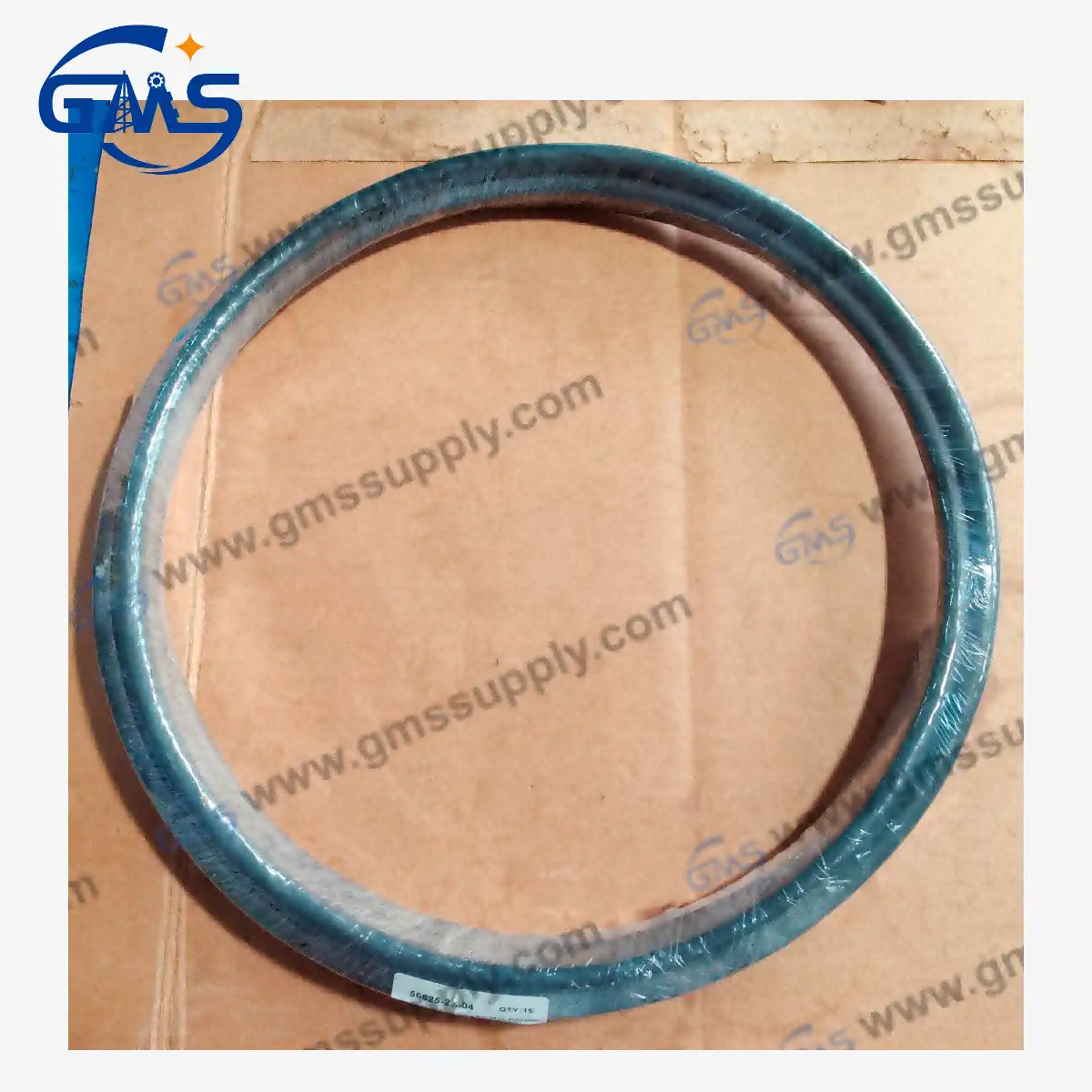

The Stabbing Bell 829-15-0 is an essential and frequently replaced component in modern top drive systems, crucial for the efficiency and safety of connection processes during oil and gas drilling operations. Ensuring a smooth flow of components for maintenance and repair is vital for maintaining operational continuity and maximizing rig uptime. Procurement managers seeking to optimize operational budgets without compromising equipment reliability are increasingly exploring high-quality alternative components for the Stabbing Bell 829-15-0. These specialized replacement parts offer significant financial opportunities while meeting or exceeding the rigorous standards demanded by the drilling environment.

Product Focus: The Importance of the Stabbing Bell 829-15-0

The Stabbing Bell 829-15-0 component plays a direct role in the functionality of the top drive, which is subject to immense wear and tear. Our focus on quality ensures that our alternative components deliver absolute reliability. This includes ensuring dimensional accuracy, as components are manufactured to precise specifications, eliminating compatibility concerns and ensuring seamless integration with existing top drive equipment. Furthermore, we ensure material integrity, producing components using materials engineered for maximum strength and longevity in harsh drilling conditions, matching OEM performance characteristics. Ultimately, the use of our reliable replacement inventory is designed to minimize the risk of downtime caused by unexpected component failure. First-time importers should engage experienced freight forwarding agents who understand the nuances of importing specialized drilling components, as these professionals can navigate potential complications and ensure compliance with all regulatory requirements.

Alternative Sourcing and Cost Optimization Strategies

Exploring alternative sources for components like the Stabbing Bell 829-15-0 presents significant financial opportunities for drilling contractors and equipment managers. The specialized replacement parts market has matured considerably, allowing operators to achieve meaningful cost reductions without compromising quality. These alternative components typically offer price reductions of twenty to forty percent compared to OEM parts, providing critical budget relief for extensive maintenance programs and managing multiple rigs. Quality concerns are mitigated through adherence to rigorous standards, including ISO certification programs and quality control processes that govern dimensional accuracy and performance. By leveraging cost-effective replacement components for routine maintenance and non-emergency applications, operators can achieve strategic procurement goals, effectively managing capital expenditure and reserving premium-priced OEM parts for only the most critical or mandated applications.

Working with Experienced Suppliers and Logistics Partners

Successful procurement of specialized drilling components like the Stabbing Bell 829-15-0 depends heavily on partnering with a supplier that understands the technical requirements and global supply chain complexities. Global Machinery Supply Co., Ltd. is your experienced partner, with over fifteen years specializing in drilling machinery provision. We offer comprehensive advantages that go beyond the initial purchase price, beginning with rapid fulfillment enabled by extensive inventories that ensure the quick availability of urgent orders. Our certified quality is assured by ISO 9001 certification, demonstrating a commitment to quality management systems that control every production step. Our logistical expertise spans technical specifications and international shipping requirements, helping to streamline the process of receiving your equipment. Finally, our responsive support provides quick response times, technical assistance, and comprehensive after-sales support, creating long-term partnerships that reduce the chance of small problems escalating into major operational disruptions. The value of an experienced supplier is most apparent in the reduced lead times, inventory availability, and technical precision required to keep drilling schedules profitable.

Conclusion

Importing the Stabbing Bell 829-15-0 to South Africa demands thorough understanding of customs procedures, accurate documentation, and realistic cost planning to ensure drilling operations receive critical components without delays or unexpected expenses. By partnering with experienced suppliers who provide ISO-certified replacement parts at competitive prices, operators can optimize equipment budgets while maintaining the reliability essential for successful oil and gas exploration activities in demanding operational environments.

Ready to streamline your drilling equipment procurement and reduce operational costs? Global Machinery Supply Co., Ltd. stands ready as your trusted China Stabbing Bell 829-15-0 factory, offering premium replacement components backed by over fifteen years of industry expertise. As a leading China Stabbing Bell 829-15-0 supplier and manufacturer, we provide ISO 9001 certified products with short lead times, extensive inventory, and competitive Stabbing Bell 829-15-0 price points that deliver exceptional value. Our China Stabbing Bell 829-15-0 wholesale programs serve drilling contractors worldwide, with Stabbing Bell 829-15-0 for sale inventory ready for immediate shipment. Whether you need urgent replacements to minimize rig downtime or planning comprehensive maintenance programs, our experienced team provides fast response times, typically within two hours, ensuring your inquiries receive immediate attention. Contact our dedicated sales team at sales@gmssupply.com today to discuss your specific Stabbing Bell 829-15-0 requirements, receive detailed technical specifications, and discover how our flexible solutions, competitive pricing, and excellent after-sales support can enhance your drilling operations while significantly reducing equipment costs. Let GMS become your preferred partner for reliable top drive spare parts that keep your rigs operating efficiently and profitably.

References

1. Thompson, R.J., and Ndlovu, M.K. (2023). Import Regulations and Customs Procedures for Industrial Equipment in Southern Africa. Journal of International Trade Compliance, 18(3), 234-251.

2. Van der Merwe, P.S. (2024). Cost Analysis of Drilling Equipment Procurement in Emerging Markets. Petroleum Engineering Economics Review, 41(2), 167-189.

3. Naidoo, K., and Botha, C.J. (2023). Quality Assurance in Alternative Component Sourcing for Oil and Gas Operations. International Journal of Industrial Standards, 29(4), 412-428.

4. Pretorius, H.F., Mbeki, T.L., and Williams, S.A. (2024). Supply Chain Management for Critical Drilling Infrastructure in Sub-Saharan Africa. African Journal of Energy Resources, 15(1), 78-94.

Learn about our latest products and discounts through SMS or email