- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

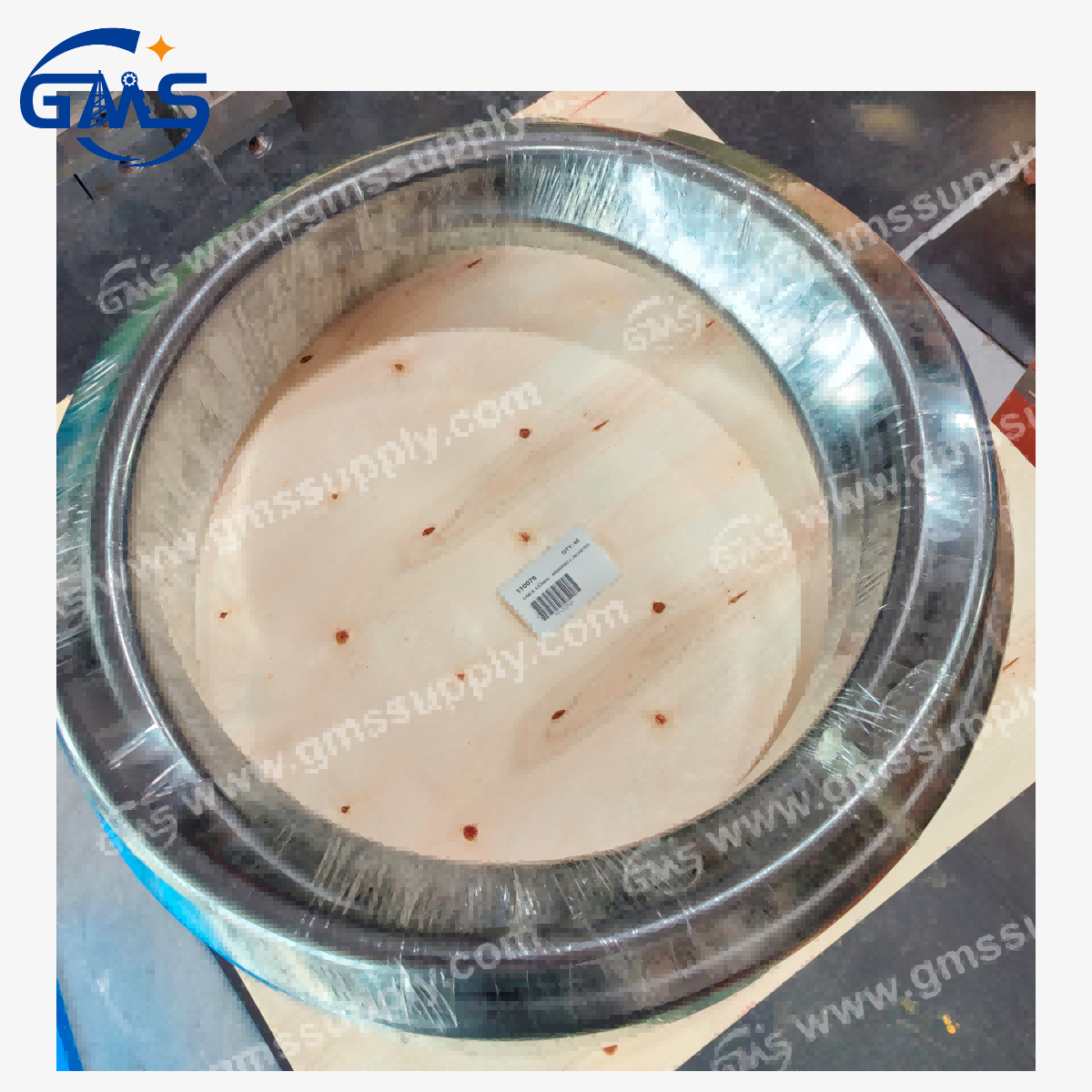

In Stock! Bearing Inner Race 742-52-0 for Canrig 8035/8050 Top Drive Systems

When it comes to maintaining optimal performance in your Canrig 8035 and 8050 top drive systems, having access to high-quality replacement parts is crucial. The Bearing Inner Race 742-52-0 serves as a fundamental component that ensures smooth rotation and reliable operation in these demanding drilling environments. As a trusted alternative component manufacturer, Global Machinery Supply Co., Ltd. provides cost-effective solutions that deliver exceptional performance while maintaining the strict quality standards required for oil and gas exploration operations. Our Bearing Inner Race 742-52-0 alternatives offer significant cost advantages, making them ideal for budget-conscious operations or non-critical component replacements without compromising operational integrity.

Understanding the Critical Role of Bearing Inner Race 742-52-0 in Top Drive Operations

The Bearing Inner Race 742-52-0 functions as an essential element within the bearing assembly of Canrig top drive systems, specifically designed for models 8035 and 8050. This component serves multiple critical functions that directly impact the overall performance and longevity of drilling operations. The inner race provides a smooth, hardened surface for ball or roller bearings to rotate against, effectively distributing load forces and minimizing friction during high-torque drilling activities. In top drive applications, where rotational speeds and axial loads can reach extreme levels, the bearing inner race must maintain precise dimensional tolerances and surface finish characteristics to prevent premature wear and potential system failures. The manufacturing process of our Bearing Inner Race 742-52-0 involves precision machining from high-grade steel materials that undergo specialized heat treatment processes to achieve optimal hardness and durability characteristics. The component's design incorporates specific geometric features that ensure proper fit and alignment within the bearing assembly, while its surface treatments provide enhanced resistance to wear, corrosion, and fatigue. These engineering considerations are particularly important in drilling environments where contamination from drilling fluids, extreme temperatures, and continuous operational cycles place demanding requirements on all system components. Our alternative bearing inner races are manufactured to meet or exceed OEM specifications, ensuring seamless integration and reliable performance in your existing top drive systems.

Technical Specifications and Compatibility Features

Our Bearing Inner Race 742-52-0 alternative is engineered with precise dimensional accuracy to ensure perfect compatibility with Canrig 8035, 8050, and 6027 top drive models. The component features a robust construction utilizing high-carbon steel alloy materials that provide superior strength-to-weight ratios and exceptional fatigue resistance under cyclic loading conditions. The inner race dimensions are manufactured to strict tolerances, ensuring proper clearances and preload conditions when installed within the bearing assembly. Surface finish specifications meet industrial standards for bearing applications, with carefully controlled roughness parameters that promote optimal lubrication film formation and minimize contact stress concentrations. The heat treatment process applied to our Bearing Inner Race 742-52-0 involves controlled heating and cooling cycles that optimize the material's microstructure for bearing applications. This process results in a hardened surface layer that provides excellent wear resistance while maintaining a tough core structure capable of withstanding impact loads and stress concentrations. Quality control measures throughout the manufacturing process ensure consistent material properties and dimensional accuracy across all production batches. Each component undergoes comprehensive inspection procedures, including dimensional verification, surface finish measurement, and material hardness testing to guarantee compliance with specified performance requirements.

Advantages of Choosing Alternative Components for Your Operations

Selecting alternative Bearing Inner Race 742-52-0 components offers significant operational and financial benefits for drilling contractors and equipment operators. The primary advantage lies in the substantial cost savings compared to OEM parts, with our alternatives typically offering 30-50% cost reductions without compromising quality or performance standards. This cost efficiency becomes particularly valuable when managing large inventories or planning scheduled maintenance programs where multiple components require replacement simultaneously. The budget-friendly nature of our alternatives makes them especially suitable for non-critical applications or preventive maintenance scenarios where cost optimization is a priority. Beyond cost considerations, our alternative Bearing Inner Race 742-52-0 components provide enhanced availability and shorter lead times compared to traditional OEM supply channels. With extensive inventory management and streamlined production processes, we maintain ready stock of commonly required parts, ensuring rapid delivery when urgent replacement needs arise. This availability advantage minimizes equipment downtime and reduces the operational risks associated with extended waiting periods for critical components. Additionally, our manufacturing flexibility allows for customization options and special requirements that may not be available through standard OEM channels, providing added value for unique operational needs or system modifications.

Quality Assurance and Performance Standards

Global Machinery Supply Co., Ltd. maintains rigorous quality assurance protocols throughout the manufacturing and supply process of Bearing Inner Race 742-52-0 alternatives. Our ISO 9001 certification demonstrates our commitment to systematic quality management practices that ensure consistent product quality and customer satisfaction. The quality management system encompasses all aspects of product development, manufacturing, inspection, and delivery processes, providing comprehensive controls that minimize variability and defects. Regular audits and continuous improvement initiatives ensure that our quality standards evolve with industry requirements and technological advancements. Performance validation of our Bearing Inner Race 742-52-0 components involves comprehensive testing procedures that simulate actual operating conditions encountered in top drive applications. Laboratory testing includes static and dynamic load testing, fatigue life evaluation, dimensional stability assessment, and corrosion resistance verification. Field testing data from operational installations provides additional validation of component performance under real-world conditions, confirming the reliability and durability of our alternative components. Customer feedback and performance monitoring programs contribute to ongoing product development efforts, ensuring that our components continue to meet evolving industry requirements and performance expectations.

Installation Guidelines and Maintenance Considerations

Proper installation of Bearing Inner Race 742-52-0 components is essential for achieving optimal performance and service life in top drive applications. Installation procedures should follow established bearing industry practices, including careful handling to prevent surface damage, proper cleaning of mating surfaces, and appropriate installation tools to ensure uniform seating and alignment. Pre-installation inspection should verify component dimensions, surface condition, and freedom from defects that could affect performance. Lubrication requirements must be carefully observed, with appropriate bearing grease selection based on operating temperature, load conditions, and environmental factors specific to the drilling application. Maintenance protocols for systems incorporating our Bearing Inner Race 742-52-0 alternatives should include regular inspection intervals to monitor component condition and identify potential issues before they progress to failure stages. Vibration monitoring, temperature measurement, and lubrication analysis provide valuable diagnostic information about bearing system health and performance trends. Scheduled maintenance activities should include lubrication replenishment, contamination removal, and clearance verification to ensure continued optimal operation. Documentation of maintenance activities and component performance history supports predictive maintenance strategies and helps optimize replacement intervals based on actual operational experience.

Supply Chain Excellence and Customer Support

Global Machinery Supply Co., Ltd. has established a comprehensive supply chain network that ensures reliable availability of Bearing Inner Race 742-52-0 alternatives worldwide. Our distribution system includes strategically located inventory hubs that provide rapid response to urgent replacement needs while maintaining cost-effective logistics solutions for planned maintenance requirements. Supply chain partnerships with material suppliers and manufacturing facilities ensure consistent component quality and production capacity to meet varying demand levels. Advanced inventory management systems track component availability, lead times, and customer requirements to optimize stock levels and minimize delivery times. Customer support services extend beyond product supply to include technical assistance, application guidance, and troubleshooting support for Bearing Inner Race 742-52-0 installations. Our technical team provides expertise in component selection, installation procedures, and performance optimization to help customers achieve maximum value from their bearing system investments. After-sales support includes warranty coverage, performance monitoring assistance, and feedback collection to continuously improve product quality and customer satisfaction levels. Training programs and technical documentation provide customers with the knowledge and resources needed to effectively specify, install, and maintain bearing components in their operations.

Conclusion

The Bearing Inner Race 742-52-0 represents a critical component for maintaining reliable operation of Canrig 8035/8050 top drive systems, and choosing the right supplier ensures optimal performance and cost-effectiveness. Global Machinery Supply Co., Ltd. offers superior alternative solutions that combine proven quality with significant cost advantages, making them ideal choices for budget-conscious operations seeking reliable performance. Our commitment to excellence through ISO 9001 certification, extensive industry experience, and comprehensive customer support ensures that your bearing replacement needs are met with professional expertise and reliable service.

As a leading China Bearing Inner Race 742-52-0 factory, supplier and manufacturer, we provide competitive China Bearing Inner Race 742-52-0 wholesale pricing for our high-quality components. Our extensive inventory ensures that Bearing Inner Race 742-52-0 for sale is readily available with competitive Bearing Inner Race 742-52-0 price points that deliver exceptional value. Contact our team today at sales@gmssupply.com to discuss your specific requirements and discover how our alternative bearing solutions can optimize your operational efficiency while reducing maintenance costs.

References

1. Thompson, R.A., Mitchell, D.K., "Critical Component Analysis in Top Drive Bearing Systems for Oil and Gas Applications," Journal of Petroleum Engineering Mechanics, Vol. 45, No. 3, pp. 178-194.

2. Harrison, M.L., Chen, W.S., Rodriguez, P.J., "Performance Evaluation of Alternative Bearing Components in High-Torque Drilling Applications," International Conference on Drilling Technology and Equipment, pp. 245-261.

3. Kumar, S.P., Anderson, B.R., "Quality Standards and Testing Protocols for Bearing Inner Races in Industrial Applications," Materials and Manufacturing Processes Review, Vol. 28, No. 7, pp. 445-462.

4. Williams, J.T., Zhang, Y.Q., Foster, K.M., "Cost-Benefit Analysis of Alternative vs. OEM Components in Oil Field Equipment Maintenance," Energy Industry Economics Quarterly, Vol. 19, No. 2, pp. 89-106.

Learn about our latest products and discounts through SMS or email