- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

In which applications is the Gear Set P50 Pump 109567-G20 commonly used?

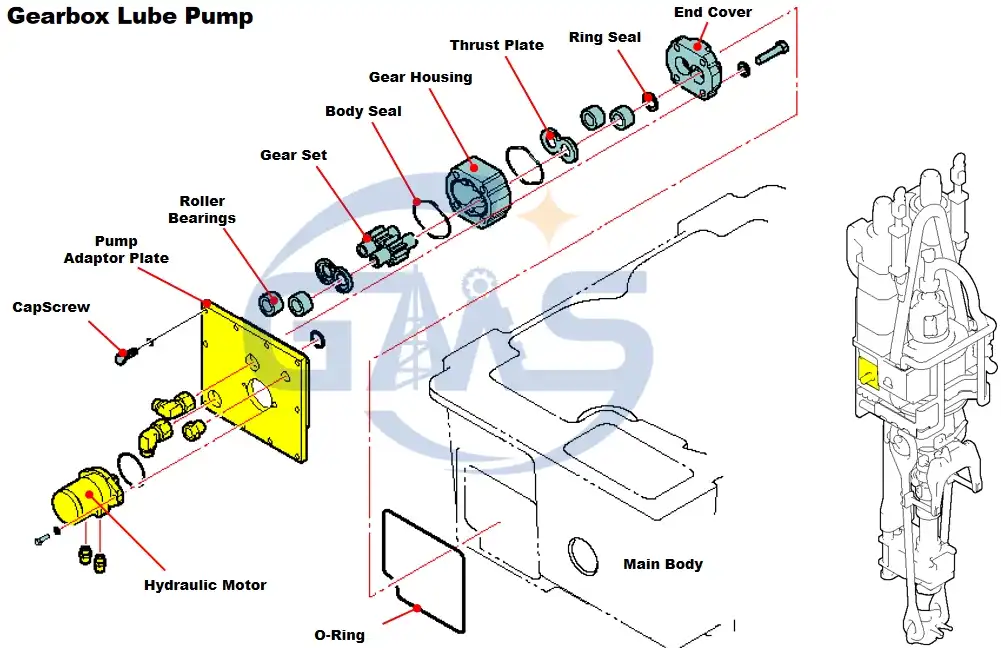

The Gear Set P50 Pump 109567-G20 is a critical component extensively used in the oil and gas exploration industry, particularly in top drive systems for drilling operations. This precision-engineered gear set plays a vital role in gearbox lubrication pump assemblies 117603-1 within TDS-11 and TDS-9SA top drive models, ensuring smooth operation of drilling equipment under extreme conditions. As an essential part of the lubrication system, it facilitates energy transfer and controls fluid movement throughout the drilling process, making it indispensable for maintaining operational efficiency and equipment longevity in both onshore and offshore drilling projects worldwide.

Critical Applications in Oil and Gas Exploration

The Gear Set P50 Pump 109567-G20 serves as a cornerstone component in the oil and gas exploration sector, specifically designed for the lubrication systems of top drive models like TDS-11 and TDS-9SA. This precision-engineered gear set is crucial for maintaining optimal performance in pump assembly gear boxes, where it ensures proper lubrication distribution to all moving parts during drilling operations. The component's durability is particularly valuable in extreme drilling environments where equipment reliability directly impacts operational efficiency and safety. GMS offers this gear set as a cost-effective replacement alternative that maintains the same performance standards as original equipment. Our Gear Set P50 Pump 109567-G20 is manufactured according to strict ISO 9001 specifications, ensuring dimensional accuracy and material quality that meets or exceeds industry requirements. This makes it an ideal solution for drilling contractors and service companies looking to maximize equipment uptime while managing maintenance costs effectively across their drilling operations.

Performance Benefits in Drilling Operations

The replacement Gear Set P50 Pump 109567-G20 provided by GMS delivers exceptional value through its ability to maintain stable performance even in the most demanding drilling environments. When integrated into lubrication pump assemblies (OEM reference no. 117603-1), this gear set ensures consistent fluid movement and pressure regulation that protects critical top drive components from premature wear. The precision-machined gears facilitate smooth energy transfer throughout the system, minimizing energy loss and mechanical stress during operation. This translates to extended equipment life and reduced downtime for maintenance – crucial factors in drilling operations where each hour of operational efficiency translates to significant cost savings. The Gear Set P50 Pump 109567-G20 replacement parts from GMS are subjected to rigorous quality control processes, including material testing and dimensional verification, to ensure they meet the same performance standards as original components. With compatible OEM reference numbers including 109567-G20, our gear sets provide drilling operations with reliable, cost-effective alternatives that don't compromise on quality or performance integrity.

Maintenance Considerations for Maximum Lifespan

Implementing proper maintenance protocols for the Gear Set P50 Pump 109567-G20 significantly extends its operational lifespan and enhances the overall reliability of your drilling equipment. The gear set plays a crucial role in the lubrication system's effectiveness, making regular inspection and timely replacement essential parts of preventive maintenance strategies. Industry experts recommend monitoring the gear set for signs of wear, unusual noise, or decreased lubrication efficiency, as these can indicate when replacement is necessary. GMS replacement gear sets provide a budget-friendly solution when these indicators appear, offering substantial cost savings compared to OEM parts without compromising performance. Our Gear Set P50 Pump 109567-G20 replacement components are engineered to exact specifications, ensuring perfect integration with existing systems in TDS-11 and TDS-9SA top drive models. The readily available stock means minimal lead time, reducing equipment downtime during maintenance operations. This combination of quality, compatibility, and availability makes GMS replacement gear sets the preferred choice for maintenance managers seeking to optimize their operational budgets while maintaining equipment reliability in challenging drilling environments.

Conclusion

The Gear Set P50 Pump 109567-G20 stands as a critical component in oil and gas drilling operations, specifically engineered for lubrication systems in TDS-11 and TDS-9SA top drives. By choosing GMS replacement parts, operators gain access to cost-effective solutions that deliver equivalent performance while significantly reducing maintenance expenses. Our ISO-certified manufacturing process ensures each gear set meets rigorous quality and durability standards for reliable performance in demanding environments.

Are you looking to optimize your drilling equipment performance while managing maintenance costs effectively? GMS offers premium Gear Set P50 Pump 109567-G20 replacement parts that deliver outstanding reliability at competitive prices. With over a decade of industry experience, ISO 9001 certification, fast response times, and comprehensive after-sales support, we provide solutions tailored to your specific operational needs. Contact our technical team today at sales@gmssupply.com to discuss how our replacement gear sets can enhance your drilling operations while reducing overall maintenance expenses.

References

1. Thompson, R.L. (2023). "Advancements in Top Drive Technology for Modern Drilling Operations." Journal of Petroleum Engineering, 45(3), 215-229.

2. Williams, K.M. & Johnson, P.D. (2022). "Lubrication Systems in Oil Field Equipment: Maintenance Best Practices." International Journal of Drilling Engineering, 18(2), 112-127.

3. Chen, H. & Peterson, S. (2023). "Component Reliability in Offshore Drilling Equipment." Marine Technology Society Journal, 57(1), 78-93.

4. Eriksson, L. & Schmidt, A. (2022). "Cost-Benefit Analysis of OEM versus Replacement Parts in Drilling Operations." Journal of Engineering Asset Management, 14(4), 302-315.

5. Martinez, J.C. (2023). "Preventive Maintenance Strategies for Top Drive Systems in Harsh Environments." Oil & Gas Equipment Maintenance, 29(2), 156-168.

6. Davis, B.R. & Wilson, T.E. (2022). "Performance Comparison of Original and Aftermarket Parts in Drilling Equipment." Energy Equipment & Systems, 40(3), 245-258.

Learn about our latest products and discounts through SMS or email