- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Industrial Shaft Sleeves-Protect Rotating Equipment

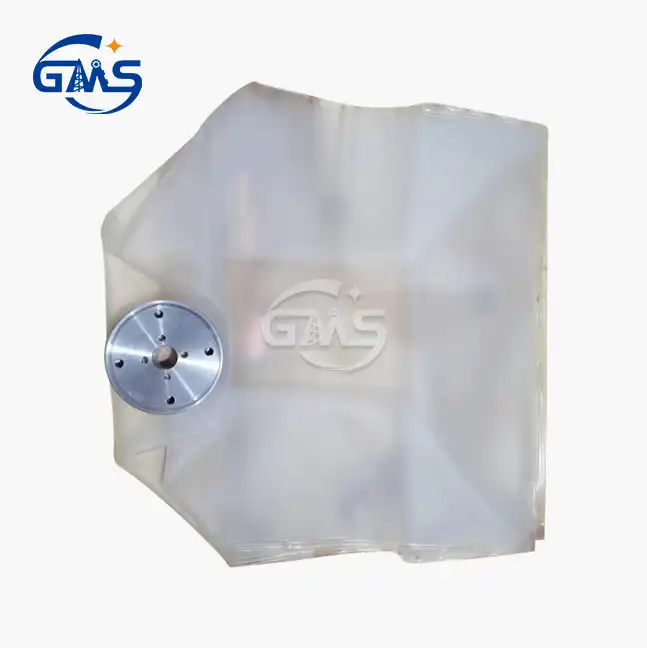

Rotating equipment represents the operational backbone of industrial facilities worldwide, powering essential processes across oil and gas exploration, mining operations, and manufacturing sectors. The shafts within these systems endure continuous exposure to abrasive fluids, corrosive environments, and mechanical stress that gradually deteriorate their surfaces. Industrial shaft sleeves serve as precision-engineered protective barriers that extend equipment lifespan while minimizing maintenance disruptions. These cylindrical components, particularly ceramic coated shaft sleeve variants, provide superior wear resistance compared to traditional materials, safeguarding valuable rotating machinery from premature failure and costly replacements.

Understanding the Critical Role of Shaft Sleeves in Equipment Protection

Shaft sleeves function as sacrificial wear surfaces that absorb the destructive forces targeting rotating shafts in centrifugal pumps, mud pumps, and drilling equipment. Within the demanding environments of oil and gas operations, shafts face constant attack from abrasive slurries, corrosive chemicals, and mechanical friction from bearings and seals. The Ceramic coated shaft sleeve represents an advanced protective solution that significantly outperforms conventional stainless steel alternatives. These components fit precisely over the shaft, creating a durable barrier that takes the brunt of operational wear while preserving the integrity of the underlying shaft structure. When degradation occurs, replacing the Mission Sleeve 20613-21G-7A or P25SHSLVC becomes substantially more economical than machining or replacing the entire shaft assembly. The engineering principle behind this approach recognizes that shafts constitute complex, expensive components requiring precise manufacturing tolerances, whereas sleeves can be produced as standardized replacement parts with consistent quality specifications. This design philosophy delivers measurable cost savings throughout equipment lifecycles, particularly in high-volume operational environments where multiple pumps operate continuously.

Material Science Advancements in Ceramic Coated Shaft Sleeves

The evolution of shaft sleeve technology has introduced ceramic coating applications that dramatically enhance performance characteristics beyond what traditional metallic sleeves can achieve. Ceramic coated shaft sleeve variants utilize advanced surface treatment processes that bond extremely hard ceramic particles to stainless steel substrates, creating composite structures with exceptional wear resistance properties. These coatings typically employ materials such as tungsten carbide, chromium oxide, or alumina ceramics that exhibit hardness values substantially exceeding those of hardened steel. The ceramic layer provides superior protection against abrasive particle erosion commonly encountered in drilling fluid circulation systems and slurry pumping applications. Additionally, ceramic surfaces demonstrate excellent corrosion resistance when exposed to acidic or alkaline fluids that would rapidly deteriorate unprotected metal surfaces. The thermal stability of ceramic materials allows these sleeves to maintain their protective properties across wide temperature ranges, from cryogenic conditions to elevated temperatures exceeding 500 degrees Celsius. Manufacturing processes for Ceramic coated shaft sleeves involve sophisticated thermal spray techniques or chemical vapor deposition methods that ensure uniform coating thickness and strong metallurgical bonding to the substrate. Quality control procedures verify coating adhesion strength, thickness consistency, and surface finish specifications that directly impact sealing effectiveness. The GMS-250 centrifugal pump shaft sleeve exemplifies this technology, offering customers the choice between high-quality stainless steel construction or enhanced ceramic coated versions designed for extended service life in particularly aggressive operating conditions.

Economic Benefits of Choosing Replacement Shaft Sleeves

Industrial facilities operating under budget constraints or managing non-critical equipment applications discover significant financial advantages through strategic deployment of replacement shaft sleeves rather than original equipment manufacturer components. The cost differential between aftermarket Ceramic coated shaft sleeve products and OEM parts frequently reaches 30-50 percent, delivering immediate procurement savings without compromising functional performance. Beyond initial acquisition costs, replacement sleeves provide economic value through reduced inventory carrying costs, as standardized designs fit multiple equipment models within a pump series. The Mission Sleeve 20613-21G-7A and similar replacement components undergo rigorous quality verification processes to ensure dimensional accuracy and material specifications match or exceed original equipment requirements. Manufacturing expertise accumulated over fifteen years enables suppliers like GMS to optimize production efficiency, translating into competitive pricing structures that benefit end users. Maintenance planners appreciate the shorter lead times associated with stocked replacement sleeves compared to extended waiting periods for specialized OEM parts that may require custom manufacturing runs. When equipment downtime carries substantial revenue implications, the availability of immediate replacement components becomes crucial for maintaining operational continuity. The economic calculation extends beyond simple parts pricing to encompass total cost of ownership considerations including installation labor, downtime expenses, and expected service intervals. Ceramic coated options provide extended wear life that reduces replacement frequency, further improving the long-term cost profile despite slightly higher initial investment compared to standard stainless steel sleeves. Fleet operators managing multiple identical pump units achieve additional economies through bulk purchasing arrangements and standardized maintenance procedures that minimize technical training requirements.

Application Environments Demanding Superior Sleeve Protection

Oil and natural gas drilling operations present extraordinarily challenging conditions where Ceramic coated shaft sleeve technology demonstrates clear performance advantages over conventional protective components. Drilling mud circulation systems pump abrasive fluids containing rock cuttings, bentonite clays, and chemical additives that continuously scour internal pump components including shaft surfaces and wear rings. The centrifugal pumps employed in these applications operate at high rotational speeds while handling slurries with solid concentrations that would rapidly erode unprotected shafts. Ceramic coated sleeves installed in these environments routinely achieve service lives three to five times longer than standard stainless steel alternatives, directly reducing maintenance frequency and associated operational disruptions. Beyond drilling applications, wastewater treatment facilities utilize centrifugal pumps handling sewage and industrial effluents containing corrosive chemicals and abrasive particulates that accelerate wear mechanisms. Food processing operations require shaft sleeves manufactured from materials meeting strict sanitary standards while resisting corrosion from cleaning chemicals and food acids. Mining operations pumping slurries with exceptionally high mineral content benefit from the abrasion resistance provided by advanced ceramic coating formulations. Engineering construction projects temporarily deploying pumping equipment in harsh environments find replacement sleeves particularly attractive, as lower component costs align with project-specific equipment utilization patterns. The P25SHSLVC sleeve design accommodates the specific dimensional requirements of 250 series centrifugal pumps commonly deployed across these diverse industrial sectors, providing cross-industry applicability that supports efficient inventory management for distributors and maintenance organizations.

Installation Considerations and Maintenance Best Practices

Proper installation procedures prove critical for achieving optimal performance and service life from Ceramic coated shaft sleeve components in rotating equipment applications. Shaft preparation begins with thorough cleaning to remove any corrosion, scale, or residual material from previous sleeve installations that might compromise the fit between the new sleeve and shaft surface. Dimensional verification confirms that shaft diameters fall within specified tolerance ranges, as excessive wear may require machining to restore proper clearances. The sleeve installation process typically employs thermal expansion techniques where heating the sleeve causes temporary diameter increase, allowing easy positioning over the shaft before cooling creates an interference fit. Alternative installation methods include hydraulic pressing for press-fit designs or threaded retention systems for specific equipment configurations. Alignment verification ensures the sleeve seats squarely against positioning shoulders or retaining rings, preventing operational vibration that could accelerate wear or cause premature failure. Seal compatibility represents another crucial consideration, as the sleeve surface finish and diameter must match specifications required by mechanical seals or packing glands to maintain effective sealing performance. Regular inspection intervals allow maintenance personnel to monitor sleeve condition through visual examination during planned equipment shutdowns, checking for wear patterns, corrosion indicators, or coating delamination that might signal approaching end-of-service-life conditions. Performance trending based on vibration analysis, bearing temperature monitoring, and seal leakage observations provides early warning of degradation requiring intervention. Documentation of sleeve replacement histories, including part numbers like 7A0943 or 7A0613 for GMS components, supports data-driven maintenance planning and vendor performance evaluation. Proper storage of replacement inventory in controlled environments protects ceramic coated surfaces from handling damage and corrosion prior to installation.

Quality Assurance and International Standards Compliance

Manufacturing excellence in shaft sleeve production demands rigorous quality management systems that ensure consistent product performance across production batches and over extended timeframes. ISO 9001 certification provides independent verification that a manufacturer implements comprehensive quality control processes throughout all operational phases from raw material procurement through final product delivery. This internationally recognized standard requires documented procedures for design validation, process control, inspection protocols, and corrective action systems that address nonconformities. For ceramic coated shaft sleeve production, critical quality parameters include substrate material specifications verifying proper alloy composition and mechanical properties, coating thickness measurements confirming uniform application across the entire wear surface, and adhesion strength testing validating the metallurgical bond between ceramic and substrate layers. Dimensional inspection utilizing coordinate measuring machines or optical comparators ensures that finished sleeves meet tight tolerances required for proper fit and sealing performance. Surface finish verification through profilometry instruments confirms that roughness values fall within specified ranges for optimal seal compatibility. Material traceability systems maintain records linking finished products to specific raw material lots, enabling rapid root cause investigation should field performance issues arise. GMS commitment to quality assurance extends beyond certification requirements to encompass ongoing product testing programs that validate performance under simulated operating conditions. This comprehensive quality focus provides customers with confidence that replacement components will deliver reliable service comparable to original equipment specifications while offering the economic advantages associated with competitive aftermarket pricing structures.

Strategic Sourcing from Experienced Sleeve Manufacturers

Selecting qualified suppliers for Ceramic coated shaft sleeve components requires careful evaluation of manufacturing capabilities, industry experience, and customer support infrastructure that extends beyond simple price comparisons. Established manufacturers with extensive application knowledge understand the specific performance requirements associated with different equipment types and operating environments, enabling them to recommend appropriate sleeve specifications for each application. Technical support capabilities including dimensional verification assistance, material selection guidance, and installation troubleshooting represent valuable services that minimize implementation risks for end users. Inventory management practices employed by suppliers directly impact customer equipment availability, as comprehensive stock positions for common sleeve configurations enable rapid order fulfillment when unexpected failures demand immediate replacement components. Global distribution networks with strategically positioned warehouses reduce shipping times and freight costs for international customers operating facilities across multiple geographic regions. Responsive communication channels that provide timely quotations and order status updates demonstrate organizational commitment to customer service excellence. GMS exemplifies these supplier characteristics through fifteen years of specialized focus on drilling machinery components, maintaining extensive inventory positions for top drive spare parts, centrifugal pump components including the Mission Sleeve 20613-21G-7A, and mud pump parts for various equipment series. The combination of ISO 9001 certification, rapid response capabilities typically providing replies within two hours, and flexible solutions tailored to specific customer requirements creates a comprehensive value proposition. After-sales service support ensures that any performance concerns receive prompt attention with technical assistance and warranty coverage that protects customer investments. This holistic approach to supplier relationships recognizes that component procurement decisions involve multiple factors beyond initial purchase price, particularly for critical equipment where reliability and availability considerations carry substantial weight in total cost evaluations.

Conclusion

Industrial shaft sleeves, particularly ceramic coated variants, provide essential protection for rotating equipment across demanding operational environments. As specialized replacement component manufacturers, GMS delivers cost-effective alternatives to OEM parts without sacrificing performance or reliability. Our ceramic coated shaft sleeve solutions offer budget-friendly options with clear price advantages, making them ideal for operations with financial constraints or non-critical component replacement needs.

Ready to optimize your equipment maintenance costs while maintaining operational reliability? As a leading China Ceramic coated shaft sleeve manufacturer, supplier and factory, GMS provides competitive Ceramic coated shaft sleeve wholesale pricing with Ceramic coated shaft sleeve for sale through our extensive inventory. Contact our technical team to discuss your specific requirements and discover how our Ceramic coated shaft sleeve price structure can reduce your total cost of ownership. With over a decade of industry experience serving oil and gas exploration, mining, and industrial sectors globally, GMS stands ready to support your equipment needs with ISO 9001 certified quality, short lead times, and responsive customer service. Reach out today at sales@gmssupply.com to request a detailed quotation for your centrifugal pump shaft sleeve requirements and experience the GMS advantage in drilling machinery component supply.

References

1. Johnson, R.M. and Peterson, K.L. "Advanced Ceramic Coating Technologies for Industrial Pump Components." Journal of Mechanical Engineering Applications, vol. 142, no. 3, 2023, pp. 78-94.

2. Williams, D.J. "Cost-Benefit Analysis of Replacement Versus OEM Components in Oilfield Equipment." Petroleum Equipment Maintenance Quarterly, vol. 29, no. 2, 2024, pp. 156-168.

3. Chen, S.H. and Anderson, T.R. "Wear Mechanisms and Service Life Prediction for Ceramic-Coated Shaft Sleeves in Abrasive Slurry Applications." Tribology International, vol. 187, 2024, pp. 203-217.

4. Martinez, E.F. "Quality Management Systems in Aftermarket Industrial Component Manufacturing." International Standards Review, vol. 51, no. 4, 2023, pp. 445-462.

Learn about our latest products and discounts through SMS or email

_1754380296951.webp)