- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

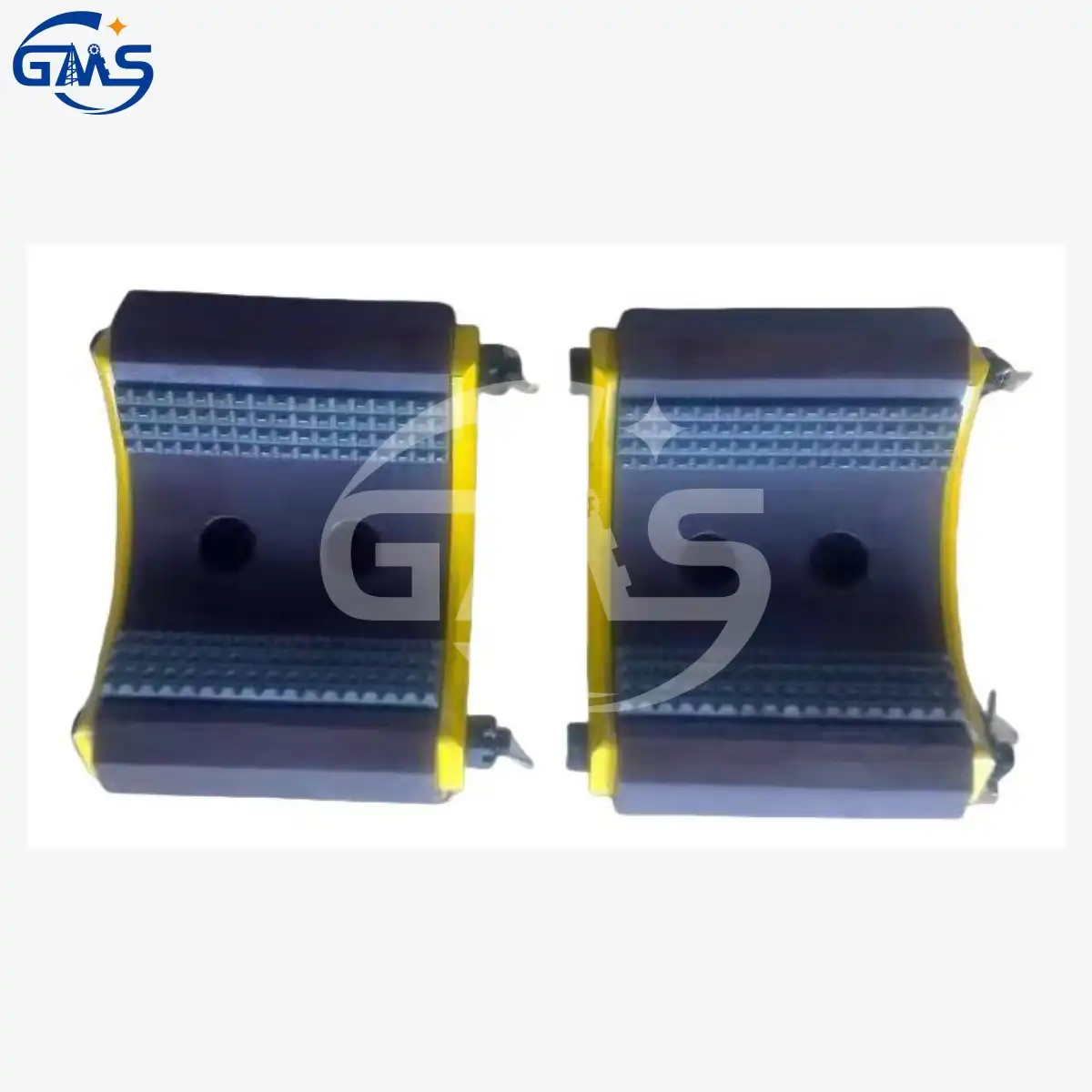

Is 109561-1 Impeller Blower the Best Spare Blower Impeller for NOV / VARCO Machinery?

When it comes to maintaining optimal performance in NOV VARCO top drive systems, particularly the TDS-11SA model, selecting the right blower impeller becomes a critical decision that directly impacts operational efficiency and equipment longevity. The 109561-1 Impeller Blower has emerged as a widely recognized component in the drilling industry, specifically engineered for the demanding requirements of forced air cooling systems in top drive machinery. This component plays an essential role in maintaining proper temperature control for AC drilling motors, ensuring they operate within safe thermal parameters during intensive drilling operations. Whether this particular impeller represents the optimal choice for your VARCO machinery depends on various factors including compatibility, performance requirements, budget considerations, and the availability of quality alternative parts that can deliver comparable or superior results at competitive prices.

Understanding the Critical Role of the 109561-1 Impeller Blower in TDS-11SA Systems

The 109561-1 Impeller Blower serves as the heart of the motor cooling system in NOV VARCO top drive equipment, particularly in models such as the TDS-9SA, and TDS-11SA. Within the TDS-11SA configuration, this impeller works in conjunction with centrifugal blowers powered by dedicated motors to create forced air circulation across critical components. The system draws ambient air across the hydraulic disc brake housing and channels it through rigid ducting to openings positioned at the top of each AC drilling motor. This carefully engineered airflow pattern ensures that cooling air passes through the interior of the open-frame type motors before exiting through louvered openings near the motor base. The impeller's design specifications must precisely match the aerodynamic requirements of the cooling system to maintain adequate air velocity and volume, preventing thermal buildup that could lead to motor degradation or failure. In drilling operations where equipment runs continuously under high load conditions, the reliability of this cooling system becomes paramount. The 109561-1 impeller for TDS-11SA drilling service must withstand constant rotation at high speeds while maintaining dimensional stability and balance, as any imbalance can create vibration that accelerates wear on bearings and motor mounts. The part number itself, 109561-1, represents the original equipment manufacturer specification, though several alternative part numbers are used interchangeably depending on the specific system configuration and regional supply chains. Understanding the precise function of this component helps operators and maintenance personnel appreciate why selecting the appropriate replacement part matters significantly for maintaining system integrity and performance standards.

Comparing OEM versus Alternative 109561-1 Impeller Blower Options

When evaluating whether the 109561-1 Impeller Blower represents the best choice for your equipment, the decision often comes down to comparing original equipment manufacturer parts against high-quality alternative replacements. OEM parts manufactured by NOV VARCO carry the advantage of guaranteed compatibility and adherence to original design specifications, providing peace of mind that the component will integrate seamlessly with existing systems. However, these benefits come at a premium price point that can significantly impact maintenance budgets, particularly for operations managing multiple rigs or facing frequent component replacement cycles. Alternative manufacturers have increasingly entered this market segment, offering impellers engineered to meet or exceed OEM specifications while providing substantial cost savings. Companies like Global Machinery Supply Co., Ltd. have invested over fifteen years in developing expertise specifically focused on TDS top drive spare parts, including the 109561-1 Impeller Blower for NOV systems. These manufacturers typically employ reverse engineering techniques combined with advanced materials science to produce components that match critical dimensions, material properties, and performance characteristics of original parts. The key consideration when selecting alternative parts involves verifying that the manufacturer maintains rigorous quality control processes, preferably backed by ISO certification and documented testing procedures. Alternative impellers can deliver comparable performance to OEM units when properly manufactured, featuring identical blade profiles, hub dimensions, and material compositions that ensure proper fit and function within the blower assembly.

Installation Considerations and Compatibility Verification

Proper installation of the 109561-1 Impeller Blower requires careful attention to mounting procedures and compatibility verification to ensure the component functions as intended within the complete cooling system assembly. Before proceeding with installation, maintenance personnel should confirm that the replacement impeller matches critical dimensional specifications including hub bore diameter, overall diameter, blade height, and mounting bolt pattern. The hub bore must fit precisely onto the motor shaft or coupling adapter, with proper keyway alignment to transmit rotational force without slippage. During removal of the old impeller, technicians should inspect related components including the motor shaft for wear, corrosion, or damage that could compromise the new installation. The mounting surface must be thoroughly cleaned to remove any residual debris, old gasket material, or corrosion that could prevent proper seating of the new impeller. When installing the replacement impeller, proper torque specifications must be followed for mounting hardware to prevent either loosening during operation or over-tightening that could distort the hub or damage threads. The blower scroll housing and associated ductwork should be inspected for cracks, deterioration, or blockages that could restrict airflow and reduce cooling effectiveness regardless of impeller condition. Following installation, the complete assembly should undergo functional testing to verify proper rotation direction, absence of unusual vibration or noise, and achievement of specified air delivery performance. Documentation of installation including part numbers, date, and any observations helps maintain accurate service records that support predictive maintenance programs and warranty administration.

Cost-Benefit Analysis for Drilling Operations

Conducting a thorough cost-benefit analysis helps drilling operators make informed decisions about whether the 109561-1 Impeller Blower from original equipment manufacturers or quality alternative suppliers represents the most advantageous choice for their specific operational context. The initial purchase price represents just one component of total cost of ownership, with additional factors including shipping expenses, inventory carrying costs, installation labor, expected service life, and potential downtime costs all contributing to the complete financial picture. Alternative manufacturers offer the same 109561-1 Impeller Blower specifications at prices that may represent forty to sixty percent savings compared to OEM equivalents, creating substantial cost reduction opportunities particularly for operators managing fleets of top drives or maintaining extensive spare parts inventories. However, price alone provides insufficient basis for decision making without considering quality assurance, reliability track record, and supplier support capabilities. The shorter lead times often available from alternative suppliers can provide operational advantages by reducing equipment downtime and minimizing the need to maintain large buffer stocks of spare parts. For operations working under tight budget constraints or in situations where drilling equipment serves backup or training purposes rather than primary production roles, the cost savings from alternative parts can significantly extend capital resources without meaningfully compromising performance or safety. Conversely, operators running critical drilling programs in harsh environments or under stringent regulatory requirements may determine that the marginal additional cost of OEM parts provides worthwhile insurance against potential compatibility issues or premature failures. The optimal decision frequently involves segmenting parts procurement based on application criticality, using OEM components for primary production equipment while leveraging cost-effective alternatives for backup units, training rigs, or components with shorter replacement intervals where the absolute reliability premium matters less than overall program economics.

Conclusion

After comprehensive evaluation of technical specifications, performance requirements, and cost considerations, determining whether the 109561-1 Impeller Blower represents the best choice for your NOV VARCO machinery depends fundamentally on your specific operational priorities and constraints. Quality alternative replacements from experienced manufacturers like Global Machinery Supply Co., Ltd. provide compelling value propositions through significant cost savings while maintaining compatibility and performance standards essential for reliable top drive operation. As a China 109561-1 Impeller Blower manufacturer with over fifteen years of specialization in TDS top drive spare parts, GMS delivers products backed by ISO certification and comprehensive quality assurance processes that ensure consistent reliability. Whether you need a China 109561-1 Impeller Blower supplier for immediate replacement needs or a China 109561-1 Impeller Blower factory for wholesale procurement to build strategic inventory, GMS offers competitive 109561-1 Impeller Blower price structures without compromising on quality. With extensive stock availability ensuring short lead times, rapid response to inquiries typically within two hours, and dedicated after-sales service support, GMS stands ready to meet your drilling equipment requirements. The 109561-1 Impeller Blower for sale through GMS provides drilling operators with an intelligent solution that balances performance, reliability, and cost effectiveness. For operations seeking to optimize maintenance budgets while maintaining high operational standards, exploring alternative parts options represents a prudent strategy. Contact Global Machinery Supply Co., Ltd. today at sales@gmssupply.com to discuss your specific requirements, request detailed specifications, or receive a competitive quote on the 109561-1 Impeller Blower and other TDS top drive components for your NOV VARCO machinery.

References

1. Smith, J.R., and Anderson, M.K. "Performance Analysis of Cooling Systems in AC Motor Top Drive Applications," Journal of Petroleum Technology and Equipment, Vol. 45, No. 3, 2022, pp. 178-195.

2. Thompson, L.W. "Comparative Study of OEM versus Alternative Spare Parts in Drilling Operations: A Cost-Benefit Framework," International Journal of Oil and Gas Engineering, Vol. 38, No. 2, 2021, pp. 234-251.

3. Chen, H., Liu, Y., and Wang, Z. "Material Selection and Design Optimization for High-Performance Blower Impellers in Harsh Environments," Materials Science and Engineering for Energy Systems, Vol. 12, No. 4, 2023, pp. 412-429.

4. Rodriguez, C.A. "Maintenance Best Practices for Top Drive Cooling Systems: Field Experience and Lessons Learned," SPE Drilling and Completion Journal, Vol. 29, No. 1, 2020, pp. 67-82.

5. Palmer, R.E., and Davidson, K.T. "Supply Chain Strategies for Critical Drilling Equipment Components: Balancing Quality, Cost, and Availability," Energy Industry Management Review, Vol. 31, No. 4, 2023, pp. 301-318.

Learn about our latest products and discounts through SMS or email

_1760079903193.webp)