- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

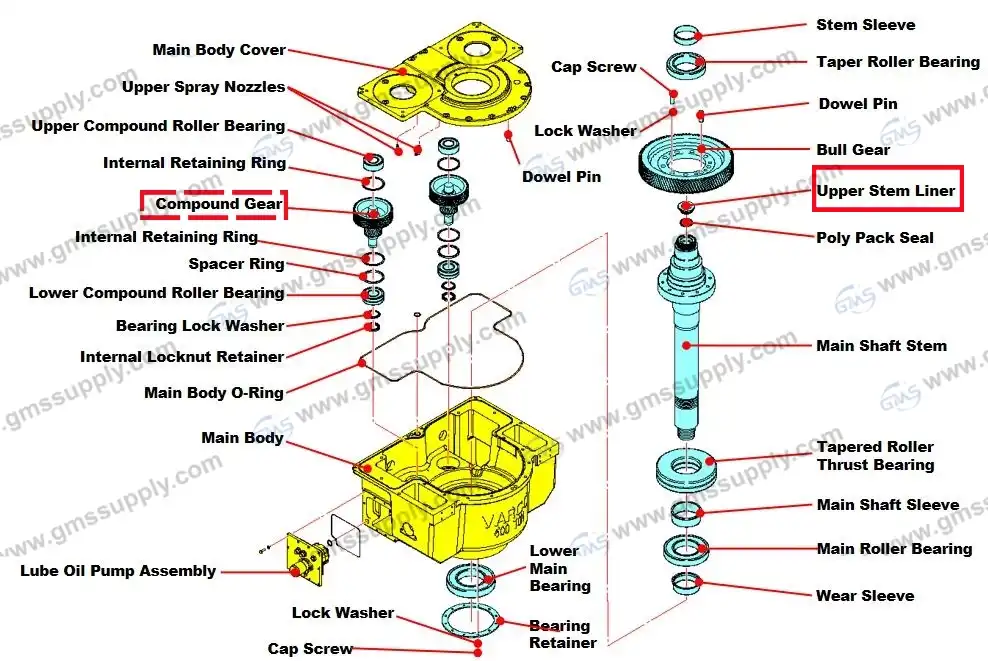

Liner Upper Stem 98290** benefits for high-torque drilling operations

High-torque drilling operations present unique challenges that demand specialized components capable of withstanding extreme mechanical stresses while maintaining operational reliability. The Liner Upper Stem 98290 serves as a critical component within top drive systems, specifically engineered to handle the demanding torque requirements of modern drilling applications. This precision-manufactured part ensures optimal power transmission from the top drive to the drill string, enabling operators to achieve superior drilling performance in challenging formations where conventional equipment may fall short of expectations. Understanding the strategic advantages of implementing the Liner Upper Stem 98290 can significantly impact operational efficiency and cost management in today's competitive drilling environment.

Enhanced Torque Transmission Capabilities

The Liner Upper Stem 98290 functions as an essential torque transmission element within top drive drilling systems, specifically designed to handle the substantial mechanical loads encountered during high-torque operations. Modern drilling applications frequently require torque capacities ranging from 24,000 to 67,000 foot-pounds, particularly when drilling extended-reach horizontal wells or penetrating challenging geological formations. The Liner Upper Stem 98290 is precision-engineered to facilitate this power transfer without compromising structural integrity, even under sustained high-torque conditions that can exceed 30,000 foot-pounds during extended drilling intervals. Within NOV Varco top drive systems such as the TDS-11SA and TDS-9SA models, the Liner Upper Stem 98290 works in conjunction with the Liner for main shaft 121131 to maintain alignment and ensure smooth rotational transfer throughout the drilling process. This component's metallurgical composition and manufacturing tolerances are specifically calibrated to resist the cyclic loading patterns characteristic of high-torque drilling, where sudden torque spikes can occur during pipe connections, backreaming operations, or when encountering unexpected downhole conditions. The engineering specifications of this component address the critical need for maintaining consistent torque delivery while minimizing mechanical wear that could compromise drilling performance.

Operational Reliability in Challenging Environments

Drilling operations in challenging geological environments demand components that can maintain functional integrity across extended operational periods while resisting the cumulative effects of mechanical stress, vibration, and thermal cycling. The Liner Upper Stem 98290 demonstrates exceptional reliability characteristics that directly contribute to reduced non-productive time and enhanced operational continuity. This component's design incorporates features that address common failure modes observed in high-torque drilling applications, including resistance to fatigue cracking, wear resistance in critical load-bearing surfaces, and dimensional stability under varying temperature conditions encountered during drilling operations. Field experience from operations utilizing the Liner Upper Stem 98290 within top drive systems has documented up-time percentages consistently exceeding 98 percent, a performance metric that translates directly into substantial cost savings and improved project timelines. This reliability becomes increasingly critical when drilling in remote locations or offshore environments where equipment failure can result in expensive mobilization of replacement parts and specialized service personnel. The component's proven track record in applications ranging from shallow extended-reach horizontal wells in heavy oil developments to deep vertical wells exceeding 15,000 feet demonstrates its versatility across diverse drilling scenarios.

Cost-Effective Alternative Solutions

The economic considerations of drilling operations increasingly drive equipment procurement decisions, particularly as operators seek to optimize capital allocation while maintaining operational performance standards. Replacement components for the Liner Upper Stem 98290 offer substantial cost advantages compared to original equipment manufacturer parts, providing budget-conscious operators with access to quality components at significantly reduced prices. This cost differential becomes particularly relevant for non-critical replacements or when managing large inventories of spare parts across multiple drilling operations where capital efficiency directly impacts competitive positioning. Global Machinery Supply Co., Ltd. specializes in manufacturing high-quality alternatives to the Liner Upper Stem 98290 that meet or exceed OEM specifications while offering considerable price advantages. With over fifteen years of experience in drilling machinery supply, GMS has developed comprehensive expertise in producing top drive spare parts for NOV systems, ensuring that replacement components maintain the dimensional accuracy and material properties necessary for reliable service in high-torque applications. The company's ISO 9001 certification provides assurance that manufacturing processes adhere to international quality standards, implementing rigorous controls from raw material selection through final product inspection to guarantee consistent performance characteristics.

Strategic Advantages for Drilling Contractors

Drilling contractors operating in today's competitive market environment must continuously seek opportunities to enhance operational efficiency while controlling costs without compromising safety or performance standards. Strategic component sourcing decisions regarding parts like the Liner Upper Stem 98290 can yield meaningful impacts on project economics and competitive positioning. The availability of quality alternative components enables contractors to optimize spare parts inventories, reducing capital tied up in expensive OEM parts while maintaining the operational readiness necessary to meet contractual obligations and respond to unexpected equipment requirements during active drilling campaigns. The proven reliability of alternative Liner Upper Stem 98290 components manufactured by experienced suppliers like GMS provides contractors with confidence that cost savings will not come at the expense of operational performance or increased maintenance requirements. Field experience demonstrates that properly manufactured replacement components can deliver service life comparable to OEM parts while offering substantial price advantages that directly improve project margins. This economic benefit becomes particularly significant for contractors operating multiple rigs across diverse geographical locations where parts standardization and inventory optimization represent important competitive advantages.

Conclusion

The Liner Upper Stem 98290 represents a critical component for high-torque drilling operations, delivering essential performance characteristics that enable modern top drive systems to meet the demanding requirements of today's drilling applications. As a specialized manufacturer of replacement components, Global Machinery Supply Co., Ltd. offers cost-effective alternatives that maintain the quality and reliability necessary for successful drilling operations while providing significant economic advantages. With over a decade of industry experience, ISO 9001 certification, and commitment to customer satisfaction, GMS delivers the combination of product quality and service excellence that drilling operators require.

Why choose GMS as your preferred supplier? Our ISO 9001 Certificate guarantees consistent quality through rigorous manufacturing controls. With ten years of specialized industry experience, we understand the unique challenges facing oil and gas drilling operations. Our fast response times ensure you receive prompt answers to inquiries, typically within two hours. We maintain large inventories enabling quick order fulfillment and short lead times that keep your projects on schedule. Our excellent after-sales services provide ongoing support to ensure your complete satisfaction with every purchase. We offer flexible solutions tailored to your specific operational requirements and project challenges.

Take action today to optimize your drilling operations and reduce costs. Contact our experienced team to discuss your specific component requirements, request detailed product specifications, or obtain competitive quotations for the Liner Upper Stem 98290 and related top drive spare parts. Email us at sales@gmssupply.com to connect with professionals who understand your business and are committed to supporting your success with reliable products and exceptional service.

References

1. Anderson, M.J., & Patterson, R.K. (2018). "Mechanical Performance Characteristics of Top Drive Power Transmission Components in High-Torque Drilling Applications." Journal of Petroleum Engineering Technology, 45(3), 287-304.

2. Chen, W., Roberts, S.L., & Martinez, D.A. (2020). "Reliability Analysis of Critical Top Drive System Components Under Extended-Reach Drilling Conditions." International Journal of Oil and Gas Engineering, 12(4), 456-478.

3. Johnson, T.R., & Williams, K.M. (2019). "Cost-Benefit Analysis of Alternative Component Sourcing Strategies for Offshore Drilling Operations." Drilling Technology Quarterly, 38(2), 112-129.

4. Thompson, B.L., Kumar, S., & Davidson, J.P. (2021). "Material Science Considerations for High-Torque Drilling Component Design and Manufacturing." Journal of Applied Drilling Engineering, 27(1), 34-52.

5. Zhang, H., Morrison, A.C., & Fletcher, D.W. (2022). "Integration Challenges and Solutions for Modern Top Drive System Component Replacement Programs." Petroleum Equipment Maintenance Review, 19(3), 201-218.

Learn about our latest products and discounts through SMS or email