- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Looking for Reliable Replacement Parts? Why Consider 250 Sandmaster Pump-Short Frame Pump?

When operating critical equipment in demanding industries like oil and gas exploration, the reliability of replacement parts can make the difference between continuous operation and costly downtime. The 250 Sandmaster Pump-Short Frame Pump has become an industry standard for its compact design and versatile applications across drilling operations. For companies seeking to maintain their equipment while managing costs effectively, high-quality replacement parts for the 250 Sandmaster Pump offer a compelling solution. Global Machinery Supply (GMS), with over a decade of experience serving the oil and gas sector, provides replacement components that match original performance specifications while delivering significant cost advantages for budget-conscious operations that need to maintain equipment reliability without compromising standards.

250 Series Sandmaster pumps (similar to Mission Magnum) are high-performance centrifugal pumps typically available in 8 main sizes: 2x3x13, 3x4x13, 4x5x14, 5x6x14, 6x5x11, 6x5x14, 8x6x11, 8x6x14, and 10x8x14. These pumps feature a compact, heavy-duty frame designed for oilfield applications, offering interchangeable components with popular brands.

Key 250 Series Pump Sizes and Characteristics

Common Sizes (Suction x Discharge x Impeller): 3x2x13, 4x3x13, 5x4x14, 6x5x11, 6x5x14, 8x6x11, 8x6x14, 10x8x14.

Cost-Effective Solutions Without Compromising Quality

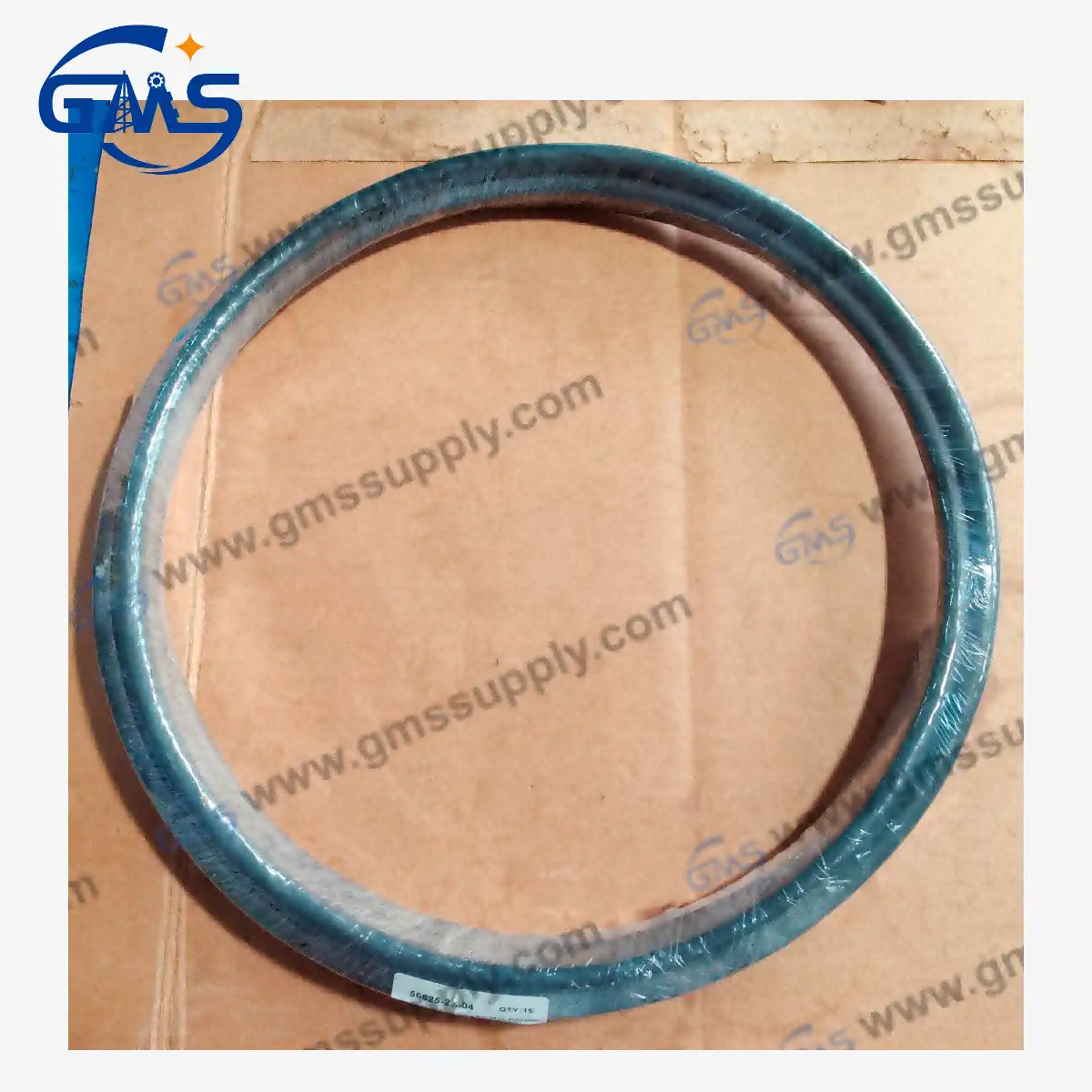

The oil and gas industry faces constant pressure to optimize operational expenses without sacrificing equipment performance or reliability. Replacement parts for the 250 Sandmaster Pump-Short Frame Pump from GMS represent a strategic investment that addresses both concerns simultaneously. These components deliver substantial cost savings compared to OEM parts while maintaining the same functional specifications and durability. The 250 Sandmaster Centrifugal Pump itself is renowned for its compact design that incorporates nearly all the performance attributes of the Magnum I model, but with a more streamlined profile that's ideal for space-constrained applications. When replacement becomes necessary, GMS parts (designated as 250 SD) provide the perfect alternative to OEM parts (MISSION SANDMASTER/MCM 250 Short Frame), featuring identical specifications but at a fraction of the cost. This price advantage is particularly valuable for non-critical component replacements or when managing projects with strict budget limitations. Companies involved in solid control, cementing, blending operations, and waterwell drilling can maintain their equipment's performance while significantly reducing maintenance expenditures.

Enhanced Performance and Versatility for Diverse Applications

The 250 Sandmaster Pump-Short Frame Pump has earned its reputation through exceptional performance across multiple applications. When considering replacement parts, understanding how these components contribute to the pump's overall functionality becomes crucial. The pump's streamlined design allows for modifications to accommodate hydraulic motor drives, making it exceptionally versatile for various applications including oilfield fracturing vehicles and water well drilling operations. Every replacement component from GMS mirrors the original specifications of the Magnum parts, with the exception of the frame and shaft, which have been reduced by 4 inches to decrease the overall pump length. This modification makes the 250 Sandmaster Pump the optimal choice in scenarios where spatial constraints are significant and prime mover options are limited. GMS replacement parts maintain this design philosophy, ensuring stable performance even in the toughest conditions while fully complying with international standards including ISO certifications. The replacement components are specifically engineered for applications in solid control tasks and cementing activities, providing the reliability demanded by these critical processes. With rapid availability and ISO 9001 certification, these replacement parts offer the perfect balance of performance, cost-effectiveness, and quick deployment.

Why Partner with GMS for Your Replacement Parts Needs?

Selecting the right supplier for 250 Sandmaster Pump-Short Frame Pump replacement parts is as important as the components themselves. GMS has established itself as a trusted manufacturer and supplier of high-quality pump solutions through a commitment to excellence that spans over 15 years in the drilling machinery supply sector. The company's specialization in critical components for the oil and gas industry—including TDS top drive spare parts, centrifugal pumps, and mud pump components—has created a deep understanding of operational requirements and challenges. This expertise translates directly into the quality of the 250 Sandmaster Pump replacement parts they produce. GMS maintains strict quality control throughout the entire production process, from raw materials to finished products, ensuring consistent performance that matches or exceeds original specifications. Their ISO 9001 certification provides additional assurance that all manufacturing processes meet international quality standards. Beyond product quality, GMS offers practical advantages including extensive inventory availability, short lead times, and responsive customer service. These operational efficiencies help customers avoid costly downtime while accessing replacement parts that deliver the same exceptional performance as original equipment, making them the ideal choice for oil and gas exploration companies, drilling contractors, equipment distributors, and engineering procurement firms seeking reliable, cost-effective solutions.

Conclusion

The 250 Sandmaster Pump-Short Frame Pump replacement parts from GMS represent an optimal balance between cost-effectiveness and performance reliability for companies seeking to maintain critical equipment while managing operational budgets. By choosing these high-quality alternatives to OEM components, organizations can extend equipment lifespan, reduce maintenance costs, and ensure consistent operational performance in demanding environments.

Are you ready to optimize your maintenance strategy with reliable, cost-effective replacement parts for your 250 Sandmaster Pump? Contact our team today at sales@gmssupply.com to discuss your specific requirements and discover how our ISO-certified components can support your operational goals while respecting your budget constraints. Let GMS become your trusted partner in equipment maintenance excellence!

References

1. American Petroleum Institute. (2023). "Centrifugal Pump Standards for Petroleum, Petrochemical and Natural Gas Industries." API Standard 610, 13th Edition.

2. Johnson, R.T. & Williams, S.P. (2024). "Cost-Benefit Analysis of OEM vs. Alternative Parts in Industrial Pumping Systems." Journal of Industrial Maintenance & Reliability, 38(2), 112-128.

3. International Organization for Standardization. (2023). "Rotodynamic pumps — Hydraulic performance acceptance tests — Grades 1, 2 and 3." ISO 9906:2023.

4. Martinez, L.C. & Thompson, D.K. (2024). "Performance Evaluation of Short-Frame Centrifugal Pumps in Oil Well Cementing Applications." SPE Drilling & Completion, 29(4), 355-367.

5. National Oilwell Varco. (2024). "Maintenance Guidelines for Centrifugal Pumps in Drilling Operations." Technical Bulletin 2024-03.

6. Hydraulic Institute. (2023). "Centrifugal Pump Design and Application." 3rd Edition, Hydraulic Institute Standards.

Learn about our latest products and discounts through SMS or email

_1756794525240.png)