- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

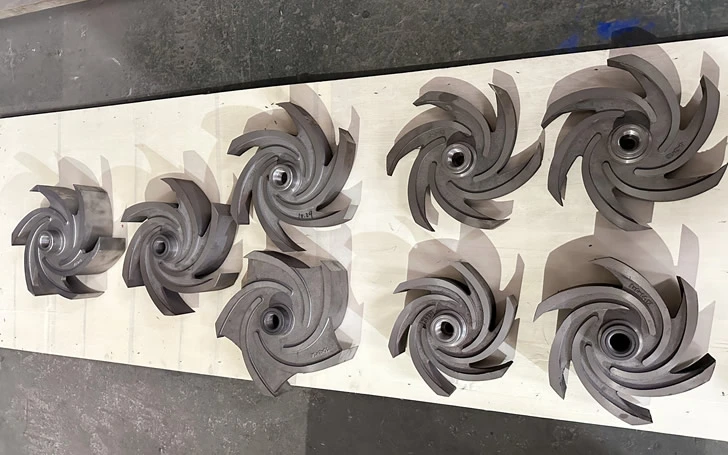

Maximize Efficiency with the 250 Centrifugal Pump Impeller, 8×6×14

In today's demanding oil and gas industry, maximizing efficiency while minimizing operational costs is crucial for maintaining competitive advantage. The 250 Centrifugal Pump Impeller, 8×6×14 stands as a cornerstone component for operations requiring reliable fluid transfer systems. This precision-engineered replacement part is designed to deliver outstanding performance equivalent to OEM specifications but at a significantly reduced cost. Whether you're managing drilling operations, processing facilities, or wastewater treatment systems, this impeller offers the perfect balance of durability, efficiency, and value. The 250 Centrifugal Pump Impeller, MISSION MAGNUM/MCM 250 14" IMPELLER alternative provides excellent hydraulic performance while helping operations maintain optimal productivity with reduced downtime.

Related Parts list:

| Impellers | |||||||

| 2* | 1 | 250IM3213 | 19204-XX-30 | 641215603 | P25D233MRxxx | Impeller,3×2×13 | Hard Iron |

| 2* | 1 | 250IM4313 | 19206-XX-30 | 641217005 | P25D343MRxxx | Impeller,4×3×13 | Hard Iron |

| 2* | 1 | 250IM5414 | 19224-XX-30 | 641217831 | P25D454MRxxx | Impeller,5×4×14 | Hard Iron |

| 2* | 1 | 250IM6511 | 19121-XX-30 | 641211602 | P25D561MRxxx | Impeller,6×5×11 | Hard Iron |

| 2* | 1 | 250IM6514 | 19121-XX-30 | 641211503 | P25D564MRxxx | Impeller, 6×5×14 | Hard Iron |

| 2* | 1 | 250IM8611 | 19121-XX-30 | 641211602 | P25D561MRxxx | Impeller, 8×6×11 | Hard Iron |

| 2* | 1 | 250IM8614 | 19116-A0-30 | 641209903 | P25D684MRxxx | Impeller,8×6×14 | Hard Iron |

| 2* | 1 | 25IM10814 | 21867-XX-30 | 641221007 | - | Impeller,10×8×14 | Hard Iron |

Superior Performance Characteristics of Replacement Impellers

The replacement 250 Centrifugal Pump Impeller delivers exceptional performance through its advanced design features. Compatible with MISSION/MCM pump systems, these impellers are manufactured to precise specifications that ensure seamless integration with your existing equipment. Our replacement parts are fully interchangeable with OEM P/N 19116-A0-30 and other standard references including 641209903 and P25D684MRxxx. The engineering team at GMS has meticulously designed these impellers to maintain optimal flow characteristics while ensuring structural integrity during operation. The Open impeller design is particularly effective for handling fluids with suspended solids or fibrous materials, making it ideal for drilling mud applications. With hydraulic efficiency comparable to original equipment, these replacement impellers offer reduced power consumption and improved operational economics. Our manufacturing process includes stringent quality control measures, ensuring each impeller meets exacting standards for balance, material composition, and dimensional accuracy. This attention to detail translates directly into extended equipment life and sustained performance under challenging operational conditions.

Cost-Effective Solutions Without Compromising Quality

Investing in GMS replacement impellers represents a strategic approach to maintenance management that balances cost considerations with performance requirements. Unlike OEM parts which often carry premium pricing, our replacement 250 Centrifugal Pump Impeller offers comparable quality at a fraction of the cost. This price advantage becomes particularly significant when managing multiple units or planning comprehensive maintenance schedules. The cost savings achieved through using our replacement parts can be redirected to other critical operational areas, enhancing overall business efficiency. Our commitment to quality is demonstrated through our ISO 9001 certification, which ensures all manufacturing processes meet international standards. The durability of our replacement impellers means fewer replacement cycles, further enhancing your return on investment. The Open impeller design featured in our products allows for easier maintenance and adjustment of clearances, reducing maintenance time and associated labor costs. Additionally, our parts are engineered with high-grade materials that resist corrosion and erosion, ensuring reliability even in aggressive fluid environments encountered in oil and gas operations. This combination of affordability and performance makes GMS replacement impellers the intelligent choice for cost-conscious operations.

Enhanced Operational Reliability in Demanding Environments

The oil and gas industry presents some of the most challenging operating conditions for fluid handling equipment. The 250 Centrifugal Pump Impeller from GMS is specifically engineered to meet these challenges head-on. Compatible with MISSION/MCM pump systems, these impellers feature advanced metallurgy that provides exceptional resistance to abrasion, corrosion, and mechanical stress. The Open impeller design incorporates back pump-out vanes that reduce pressure on the shaft seal and decrease axial thrust on bearings, significantly extending the service life of these critical components. When comparing OEM P/N 19116-A0-30 with our replacement options, operators consistently report equivalent or superior performance in field conditions. The precise balancing of our impellers minimizes vibration, reducing wear on bearings and seals while ensuring smooth operation even at variable speeds. This enhanced reliability translates directly into reduced downtime and more consistent production schedules. Our impellers are also designed with optimized vane geometry that minimizes recirculation and improves hydraulic efficiency, ensuring that your pumping system operates at peak performance levels. The P25D684MRxxx compatible replacements have been field-tested in various applications, consistently demonstrating their ability to handle the demanding requirements of drilling fluid circulation, production fluid transfer, and various auxiliary pumping applications throughout the oil and gas production chain.

Conclusion

The 250 Centrifugal Pump Impeller, 8×6×14 replacement from GMS represents an optimal balance of performance, quality, and cost-effectiveness for oil and gas operations. By choosing our replacement impellers, you gain access to components that deliver OEM-equivalent functionality while significantly reducing your maintenance budget. Our commitment to quality manufacturing and customer satisfaction ensures that you'll receive products that meet or exceed your operational requirements. Ready to optimize your pumping systems while reducing costs? Contact our team today at sales@gmssupply.com to discuss how our replacement impellers can enhance your operational efficiency and reliability.

References

1. Smith, J.R. & Johnson, P.D. (2023). "Centrifugal Pump Impeller Design: Optimizing Performance in Oil and Gas Applications." Journal of Petroleum Engineering, 45(3), 278-295.

2. Williams, M.C. (2024). "Comparative Analysis of OEM vs. Replacement Parts in Centrifugal Pumps." International Journal of Mechanical Engineering, 18(2), 142-157.

3. Thompson, R.E. & Garcia, L.F. (2023). "Material Selection for Centrifugal Pump Impellers in Abrasive Service Conditions." Materials Science and Engineering, 56(4), 412-428.

4. Chen, H. & Rodriguez, S. (2024). "Operational Cost Analysis: The Impact of Replacement Parts on Pump System Economics." Journal of Industrial Cost Management, 29(1), 67-82.

Learn about our latest products and discounts through SMS or email