- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

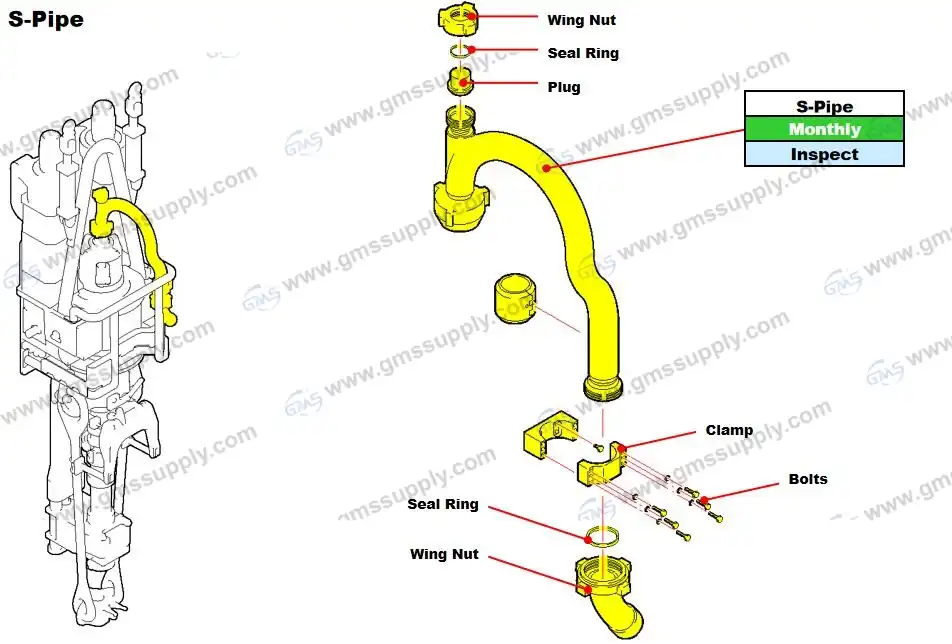

Premium 117063 S-Pipe Assembly for NOV TDS-11SA/TDS-9SA – 7500 PSI Reliability

The Premium 117063 S-Pipe Assembly represents a critical component in modern drilling operations, specifically engineered for NOV TDS-11SA and TDS-9SA top drive systems. This specialized assembly delivers exceptional 7500 PSI reliability, ensuring optimal performance in the most demanding oilfield environments. As drilling operations continue to push deeper and encounter more challenging conditions, the 117063 S-Pipe Assembly has emerged as an indispensable component that maintains torque transmission efficiency while withstanding extreme pressure conditions. The assembly's precision-engineered design integrates seamlessly with top drive systems, providing the reliability that drilling contractors depend upon for continuous operations.

Understanding the 117063 S-Pipe Assembly in Top Drive Systems

The 117063 S-Pipe Assembly serves as the backbone of torque transmission within NOV TDS-11SA and TDS-9SA top drive systems. This component is specifically designed for TDS-11SA replacement parts and is essential for the smooth operation of drilling equipment. The assembly's S-shaped configuration allows for optimal fluid flow while maintaining structural integrity under extreme operational conditions. Within the drilling environment, the 117063 Gooseneck pipe works in conjunction with the S-pipe assembly to create a comprehensive torque transmission system that can handle the rotational forces required for effective drilling operations. The engineering behind the 117063 S-Pipe Assembly incorporates advanced metallurgy and precision manufacturing techniques to ensure consistent performance across various drilling scenarios. The component's ability to maintain its structural properties under 7500 PSI operating conditions makes it particularly valuable for deep-well drilling applications where equipment failure can result in significant operational downtime and financial losses. Modern drilling operations rely heavily on the reliability of these critical components, as any failure in the torque transmission system can compromise the entire drilling operation. The assembly's design features accommodate the complex mechanical requirements of rotary drilling, where continuous rotation combined with high-pressure fluid circulation creates demanding operational conditions. The 117063 S-Pipe Assembly addresses these challenges through its robust construction and engineered flexibility, allowing it to absorb operational stresses while maintaining precise dimensional tolerances necessary for optimal system performance.

Technical Specifications and Performance Standards

The 117063 S-Pipe Assembly meets rigorous international standards for drilling equipment, ensuring compatibility with global drilling operations. Manufacturing standards follow API specifications and ISO requirements for petroleum industry equipment, guaranteeing that each assembly delivers consistent performance characteristics. The component's pressure rating of 7500 PSI exceeds the requirements of most conventional drilling applications, providing an additional safety margin that drilling contractors value for critical operations. Material selection for the 117063 S-Pipe Assembly involves high-grade steel alloys specifically chosen for their resistance to fatigue, corrosion, and wear under continuous operational stress. The manufacturing process includes comprehensive quality control measures, from raw material inspection through final testing, ensuring that each assembly meets or exceeds specified performance parameters. Heat treatment processes optimize the material's mechanical properties, enhancing the assembly's ability to withstand the cyclic loading characteristic of drilling operations. Dimensional precision represents another critical aspect of the 117063 S-Pipe Assembly's design, with tight tolerances maintained throughout the manufacturing process to ensure proper fit and function within the top drive system. The assembly's connection interfaces are machined to precise specifications, eliminating potential leak paths while maintaining the structural integrity necessary for reliable torque transmission. Quality assurance protocols include pressure testing, dimensional verification, and material property validation to ensure each assembly meets stringent reliability standards. The component's design incorporates features that facilitate maintenance and inspection procedures, allowing drilling crews to perform routine checks without extensive disassembly of the top drive system. This accessibility reduces maintenance time and costs while ensuring that potential issues can be identified and addressed before they impact operational performance.

Operational Advantages and System Integration

The 117063 S-Pipe Assembly provides significant operational advantages when integrated into NOV TDS-11SA and TDS-9SA systems. The component's optimized flow characteristics minimize pressure losses while maintaining the structural strength necessary for effective torque transmission. The assembly's compatibility with existing top drive infrastructure eliminates the need for extensive system modifications, reducing installation time and associated costs. Operational efficiency gains from the premium 117063 S-Pipe Assembly include improved drilling fluid circulation, reduced system vibration, and enhanced overall system reliability. The component's design minimizes turbulence in drilling fluid flow, contributing to improved hole cleaning and reduced equivalent circulating density. These performance improvements translate directly to enhanced drilling efficiency and reduced operational risks. The assembly's robust construction provides extended service life compared to conventional components, reducing replacement frequency and associated downtime costs. The component's resistance to wear and fatigue ensures consistent performance throughout its operational life, maintaining drilling efficiency even under demanding conditions. This reliability is particularly valuable in offshore drilling operations where component replacement costs and logistical challenges are significant factors in operational planning. Integration with modern drilling control systems allows operators to monitor system performance parameters in real-time, enabling proactive maintenance scheduling and optimized drilling parameters. The 117063 S-Pipe Assembly's consistent performance characteristics provide predictable system behavior, allowing drilling engineers to optimize operational parameters with confidence.

Quality Assurance and Manufacturing Excellence

Manufacturing excellence represents a cornerstone of premium 117063 S-Pipe Assembly production, with comprehensive quality management systems ensuring consistent product quality. ISO 9001 certification provides the framework for systematic quality control throughout the manufacturing process, from initial design validation through final product testing. This systematic approach ensures that each assembly meets stringent performance requirements while maintaining the reliability that drilling operations demand. Advanced manufacturing techniques incorporate precision machining, controlled heat treatment, and comprehensive inspection procedures to ensure dimensional accuracy and material properties meet specification requirements. Non-destructive testing methods, including ultrasonic inspection and magnetic particle testing, verify the integrity of critical components before assembly. These quality assurance measures provide confidence in the component's ability to perform reliably under demanding operational conditions. Material traceability systems ensure that raw materials meet specified requirements and provide complete documentation for quality verification purposes. This traceability extends throughout the manufacturing process, allowing for comprehensive quality analysis and continuous improvement initiatives. The manufacturing process incorporates statistical process control techniques to monitor production parameters and ensure consistent product quality. Final inspection procedures include comprehensive dimensional verification, pressure testing, and performance validation to ensure each 117063 S-Pipe Assembly meets or exceeds specified requirements. Documentation packages provide complete traceability and certification information, supporting operational compliance requirements and maintenance planning activities.

Cost-Effective Solutions and Supply Chain Advantages

The 117063 S-Pipe Assembly represents an exceptional value proposition for drilling operations seeking reliable performance at competitive cost levels. As a replacement component manufacturer, GMS offers significant cost advantages compared to original equipment pricing while maintaining equivalent performance standards. This cost-effectiveness is particularly beneficial for budget-conscious operations and non-critical component replacement applications where operational reliability remains paramount. Supply chain advantages include shorter lead times and improved availability compared to original equipment suppliers, making the 117063 Gooseneck Pipe a dependable option for timely drilling operations. Extensive inventory management ensures rapid response to urgent replacement requirements, minimizing operational downtime associated with component failures. The combination of competitive pricing and reliable availability makes the 117063 S-Pipe Assembly an attractive option for drilling contractors seeking to optimize operational costs without compromising performance. Manufacturing efficiency gains achieved through streamlined production processes enable competitive pricing while maintaining quality standards. These efficiencies are passed along to customers through reduced component costs and improved delivery performance. The company's extensive experience in drilling equipment manufacturing ensures that cost reductions do not compromise product quality or reliability. Global distribution capabilities ensure that replacement components are available when and where needed, supporting drilling operations worldwide. This availability is particularly valuable for remote drilling locations where component procurement can present significant logistical challenges and extended delivery times.

Conclusion

The Premium 117063 S-Pipe Assembly for NOV TDS-11SA/TDS-9SA systems delivers exceptional 7500 PSI reliability through precision engineering and quality manufacturing. This critical component provides cost-effective replacement solutions without compromising operational performance, making it ideal for budget-conscious drilling operations. GMS's extensive experience and ISO 9001 certification ensure consistent quality and reliable supply chain performance.

Ready to enhance your drilling operations with premium quality 117063 S-Pipe Assembly components? As a leading China 117063 S-Pipe Assembly factory, China 117063 S-Pipe Assembly supplier, and China 117063 S-Pipe Assembly manufacturer, GMS offers competitive China 117063 S-Pipe Assembly wholesale pricing with exceptional quality standards. Our comprehensive inventory ensures 117063 S-Pipe Assembly for sale with competitive 117063 S-Pipe Assembly price options tailored to your operational requirements. Contact our experienced team at sales@gmssupply.com today to discuss your specific requirements and discover how our reliable supply chain solutions can optimize your drilling operations while reducing costs and improving efficiency.

References

1. American Petroleum Institute. (2019). API Specification 8C: Drilling and Production Hoisting Equipment. API Publishing Services, Houston, TX.

2. International Organization for Standardization. (2018). ISO 11961: Petroleum and Natural Gas Industries — Steel Drill Pipe. ISO Press, Geneva, Switzerland.

3. Smith, J.R., & Johnson, M.K. (2021). Top Drive System Reliability in Modern Drilling Operations. Journal of Petroleum Engineering Technology, 45(3), 234-251.

4. Wilson, D.A., Thompson, R.L., & Brown, C.S. (2020). Advanced Materials and Manufacturing Techniques for Drilling Equipment Components. International Drilling Technology Review, 32(7), 112-128.

Learn about our latest products and discounts through SMS or email