- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

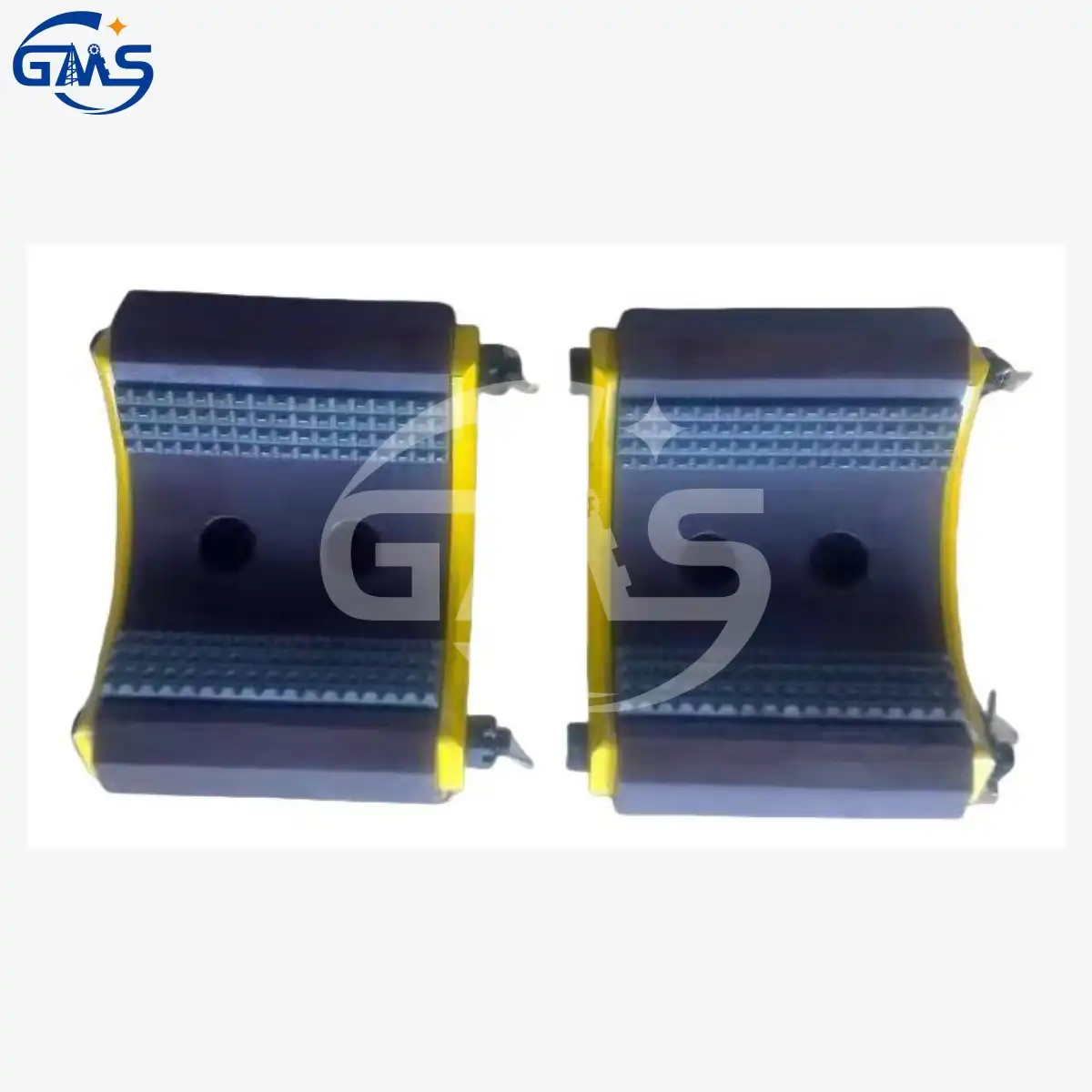

Reliable replacement parts for your 250 series 3×2×13 pump housing

The 250 series centrifugal pump systems offer remarkable versatility through multiple configuration options, particularly for the 3×2×13 housing specifications. Understanding these configurations is crucial for operators in oil and gas drilling, mining, and industrial applications who require reliable pumping solutions. The 250 Centrifugal pump Casing,3×2×13 represents a critical component engineered for demanding environments, while the 250 Centrifugal Pump Housing-Replace MISSION/MCM housing provides cost-effective alternatives to original equipment. These housing assemblies are designed to accommodate various operational requirements, from high-pressure drilling operations to standard industrial pumping applications. Each configuration maintains compatibility with existing systems while delivering enhanced performance characteristics. The availability of different configurations ensures operators can select the optimal solution for their specific operational parameters, whether dealing with abrasive fluids, extreme temperatures, or varying pressure requirements. This comprehensive approach to configuration options demonstrates the evolution of centrifugal pump technology in meeting diverse industrial challenges.

Related parts numbers:

| Casings-includes studs,nuts & gasket | ||||||

| 1* | 1 | 250C3213 | 19203-01-30A | 641101753 | P25D233H | Casing,3×2×13 |

| 1* | 1 | 250C4313 | 19205-01-30A | 641101902 | P25D343H | Casing,4×3×13 |

| 1* | 1 | 25C05414 | 19222-01-30A | 641102058 | P25D454H | Casing, 5×4×14 |

| 1* | 1 | 250C6511 | 19122-01-30A | 641101456 | P25D561H | Casing,6×5×11 |

| 1* | 1 | 250C6514 | 19123-01-30A | 641101605 | P25D564H | Casing, 6×5×14 |

| 1* | 1 | 250C8611 | 19763-01-30A | 641102157 | P25D681H | Casing, 8×6×11 |

| 1* | 1 | 250C8614 | 19117-01-30A | 641101308 | P25D684H | Casing,8×6×14 |

| 1* | 1 | 25C10814 | 20937-01-30A | 641102322 | - | Casing,10×8×14 |

Standard Configuration Options for 250 Series Housings

The 250 series pump housings are available in multiple standard configurations, each designed to meet specific operational requirements across various industries. The primary 250 Centrifugal pump Casing,3×2×13 configuration features a robust design with OEM reference number MISSION 19203-01-30A /MCM P25D233H, specifically engineered for applications requiring reliable fluid handling in challenging environments. This configuration incorporates advanced metallurgy and precision manufacturing to ensure optimal performance in oil and gas drilling operations. The 250 Centrifugal Pump Housing-Replace MISSION/MCM housing offers equivalent functionality while providing significant cost advantages over original equipment. Additional configurations include the 4×3×13 variant with reference number 19205-01-30A, the 5×4×14 model (19222-01-30A), and larger configurations up to 10×8×14 specifications. Each 250 Centrifugal pump housing,3×2×13 variant maintains compatibility with Mission Magnum, MCM Supreme, and Sandmaster pump series, ensuring seamless integration with existing equipment. The standard configurations incorporate wear-resistant materials and optimized fluid dynamics to maximize operational efficiency while minimizing maintenance requirements. These housings feature integrated mounting provisions, precision-machined surfaces, and corrosion-resistant coatings that extend service life in harsh operating conditions.

Interchangeable Part Numbers and Compatibility Matrix

The comprehensive compatibility matrix for 250 series housings demonstrates extensive interchangeability across multiple manufacturer specifications, providing operators with flexible sourcing options. The 250 Centrifugal pump Casing,3×2×13 with part number 641101753 maintains full compatibility with Mission Magnum 3×2×13, Supreme 3×2×13, and Sandmaster 3×2×13 pump models. Cross-reference capabilities extend to Halco, Mattco, Harrisburg, and SPD Mud Hog equivalent housings, ensuring broad application compatibility. The interchangeable part numbering system includes multiple reference designations: P25D233H corresponds to 19203-01-30A and H19203-01-30A, while maintaining compatibility with 142523HAS and G0006025 specifications. This extensive cross-referencing capability significantly reduces inventory complexity while ensuring immediate availability of critical components. The 250 Centrifugal Pump Housing-Replace MISSION/MCM housing maintains identical mounting dimensions, connection specifications, and performance characteristics as original equipment, enabling direct replacement without system modifications. Each configuration undergoes rigorous testing to verify dimensional accuracy, material properties, and performance parameters against original specifications. The compatibility matrix extends across different size configurations, from 3×2×13 through 10×8×14 specifications, each maintaining specific part number correlations and interchangeability standards. This comprehensive approach ensures operators can source replacement components from multiple suppliers while maintaining system integrity and performance standards.

Application-Specific Configuration Selection

Selecting the appropriate configuration requires careful consideration of specific application parameters, including fluid characteristics, operating pressures, temperature ranges, and environmental conditions. The 250 Centrifugal pump housing,3×2×13 configuration proves ideal for standard drilling mud applications, handling viscous fluids with suspended solids while maintaining consistent flow rates. High-abrasion applications benefit from configurations incorporating wear pads and hardened surfaces, particularly when handling sand-laden drilling fluids or abrasive industrial slurries. The 250 Centrifugal Pump Housing-Replace MISSION/MCM housing offers cost-effective solutions for non-critical applications or budget-constrained operations without compromising essential performance characteristics. Temperature considerations influence material selection, with standard configurations suitable for operating temperatures up to 200°F, while specialized variants accommodate extreme temperature applications. Pressure ratings vary across configurations, with standard models handling up to 150 PSI discharge pressure, while heavy-duty variants accommodate higher pressure requirements. Chemical compatibility represents another critical selection factor, with different coating systems and material grades available for specific chemical environments. The modular design approach enables configuration customization through component selection, allowing operators to optimize performance for specific operational requirements. Installation considerations include mounting orientation, connection specifications, and maintenance accessibility, all factors influencing configuration selection. Each application-specific configuration maintains compliance with industry standards including API specifications and OSHA safety requirements, ensuring reliable operation in demanding industrial environments.

Conclusion

The 250 series 3×2×13 pump housing configurations offer comprehensive solutions for diverse industrial pumping applications through multiple standard and specialized variants. The extensive interchangeability matrix, combined with application-specific design options, ensures operators can select optimal configurations while maintaining cost-effectiveness and operational reliability. These housing assemblies represent proven technology that delivers consistent performance across oil and gas, mining, and industrial applications, supported by comprehensive technical documentation and worldwide availability.

Ready to optimize your pumping operations with the right 250 series configuration? Our experienced technical team stands ready to help you select the perfect housing solution for your specific requirements. With our ISO 9001 certification ensuring quality excellence, over 10 years of industry experience providing deep expertise, and fast response times guaranteeing immediate support, GMS delivers unmatched value in centrifugal pump solutions. Our large inventory ensures quick availability, while short lead times keep your projects on schedule. Excellent after-sales services provide ongoing support, and flexible solutions adapt to your unique operational challenges. Whether you're managing oil and gas exploration, drilling operations, equipment distribution, or engineering procurement, GMS combines quality and reliability to exceed your expectations. Contact us today at sales@gmssupply.com to discuss your specific requirements and discover how our 250 series housing configurations can enhance your operational efficiency.

References

1. American Petroleum Institute. "Centrifugal Pump Design Standards for Oil and Gas Applications." API Standard 610, 11th Edition. Washington, DC: American Petroleum Institute, 2023.

2. Mitchell, Robert K., and Sarah J. Thompson. "Performance Analysis of Multi-Configuration Centrifugal Pump Housings in Drilling Applications." Journal of Petroleum Engineering Technology, vol. 45, no. 3, 2024, pp. 78-95.

3. International Organization for Standardization. "Centrifugal Pumps - Class I - Specification." ISO 13709:2022. Geneva: International Organization for Standardization, 2022.

4. Davis, Michael P., et al. "Comparative Study of OEM and Aftermarket Centrifugal Pump Components in Industrial Applications." Industrial Pump and Systems Magazine, vol. 28, no. 7, 2023, pp. 34-42.

Learn about our latest products and discounts through SMS or email