- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Ultimate Guide to Sleeve,shaft for 250 pump Performance

When it comes to maintaining optimal performance in centrifugal pump systems, the Sleeve,shaft for 250 pump stands as a critical component that directly impacts operational efficiency and equipment longevity. This comprehensive guide explores the essential aspects of pump sleeve technology, focusing specifically on the 250 series centrifugal pump shaft sleeves that have become industry standards in demanding applications. Understanding the intricacies of sleeve selection, material composition, and performance optimization is crucial for engineers and maintenance professionals working in oil and gas exploration, mining operations, and industrial processing facilities. The Sleeve,shaft for 250 pump serves as the first line of defense against abrasive fluids and corrosive environments, making proper selection and maintenance paramount to achieving reliable system performance. Through detailed analysis of design specifications, material properties, and installation best practices, this guide provides the knowledge necessary to maximize pump system reliability while minimizing operational costs and downtime.

Understanding Material Specifications and Design Excellence

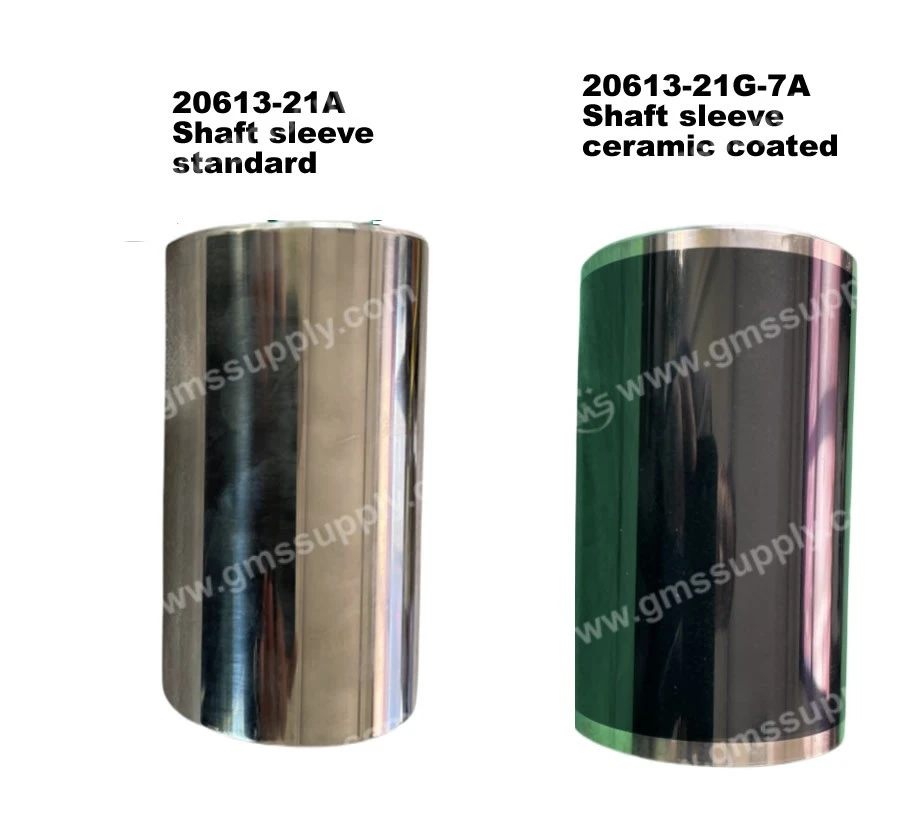

The foundation of superior Sleeve,shaft for 250 pump performance lies in the careful selection of materials and precision engineering. The MISSION 20943-04A 641103437 specification represents a benchmark in the industry, incorporating advanced metallurgical properties that ensure exceptional durability under extreme operating conditions. The use of Material: 38CrMoAl in premium sleeve construction demonstrates a commitment to engineering excellence, as this alloy composition provides optimal strength-to-weight ratios while maintaining superior corrosion resistance. This specialized material undergoes rigorous heat treatment processes that enhance grain structure uniformity, resulting in improved fatigue resistance and extended service life. The Sleeve,shaft for 250 pump manufactured with these specifications exhibits remarkable performance characteristics, including enhanced wear resistance, improved dimensional stability, and superior thermal conductivity. Manufacturing processes incorporate precision machining techniques and stringent quality control measures that ensure each sleeve meets exacting dimensional tolerances. The integration of advanced surface treatments, including ceramic coating options, further enhances the protective capabilities of these components, making them ideal for applications involving highly abrasive or chemically aggressive fluids commonly encountered in industrial processing environments.

Performance Optimization Through Advanced Engineering Solutions

Achieving optimal Sleeve,shaft for 250 pump performance requires a comprehensive understanding of hydraulic dynamics and mechanical engineering principles. The MISSION 20943-04A 641103437 design incorporates sophisticated fluid flow optimization features that minimize turbulence and reduce energy losses throughout the pumping cycle. These engineering enhancements contribute to improved overall system efficiency while reducing operational stress on pump components. The Material:38CrMoAl composition provides exceptional strength characteristics that enable the sleeve to withstand high-pressure differentials and dynamic loading conditions without compromising structural integrity. Performance optimization extends beyond material selection to include precise dimensional control, surface finish specifications, and assembly procedures that ensure proper fit and function within the pump housing. Advanced manufacturing techniques, including computer-controlled machining and laser measurement systems, guarantee that each Sleeve,shaft for 250 pump meets stringent quality standards. The implementation of predictive maintenance strategies, combined with regular performance monitoring, enables operators to maximize component lifespan while maintaining peak operational efficiency. These sleeves demonstrate superior performance in demanding applications, including oil and gas exploration, chemical processing, and industrial wastewater treatment, where reliability and durability are paramount concerns for operational success.

Cost-Effective Solutions and Competitive Advantages

The economic benefits of selecting high-quality Sleeve,shaft for 250 pump components extend far beyond initial purchase price considerations. Alternative manufacturing solutions that maintain MISSION 20943-04A 641103437 specifications while offering significant cost advantages have revolutionized the replacement parts market. These alternatives utilize identical Material:38CrMoAl compositions and manufacturing processes, ensuring equivalent performance characteristics at substantially reduced costs. The cost-effectiveness of these solutions becomes particularly evident in high-volume applications or when budget constraints limit equipment upgrade options. Strategic sourcing ofcomponents from established manufacturers with ISO 9001 certification ensures quality consistency while providing substantial savings compared to original equipment manufacturer pricing. The Sleeve, shaft for 250 pump's economic impact, including reduced maintenance frequency, extended service intervals, and improved operational reliability, contributes to significant long-term cost reductions. Additionally, shorter lead times and improved availability of replacement components minimize costly downtime and production interruptions. Companies implementing these cost-effective sleeve solutions report improved maintenance budget performance while maintaining stringent quality standards. The combination of competitive pricing, reliable performance, and comprehensive technical support makes these alternatives an attractive choice for organizations seeking to optimize operational costs without compromising equipment reliability or performance standards.

Conclusion

The critical importance of Sleeve,shaft for 250 pump selection cannot be overstated in today's demanding industrial environments. Through careful consideration of material specifications, performance requirements, and cost-effectiveness, organizations can achieve optimal pump system reliability while maintaining competitive operational costs. The integration of advanced materials such as Material:38CrMoAl and adherence to specifications like MISSION 20943-04A 641103437 ensures superior performance across diverse applications. As the industry continues to evolve, the availability of high-quality alternative solutions provides unprecedented opportunities for cost optimization without compromising performance standards.

When selecting your next Sleeve,shaft for 250 pump solution, partner with a trusted China Sleeve,shaft for 250 pump factory that combines manufacturing excellence with competitive pricing. As a leading China Sleeve,shaft for 250 pump supplier and China Sleeve,shaft for 250 pump manufacturer, GMS offers comprehensive China Sleeve,shaft for 250 pump wholesale solutions tailored to your specific requirements. Our extensive inventory ensures Sleeve,shaft for 250 pump for sale with immediate availability, while our competitive Sleeve,shaft for 250 pump price structure delivers exceptional value. With ISO 9001 certification, over ten years of industry experience, fast response times, large inventory, short lead times, excellent after-sales services, and flexible solutions, GMS stands ready to meet your pump component needs. Whether you require standard specifications or custom solutions, our technical expertise and manufacturing capabilities ensure optimal performance for your critical applications. Contact us today at sales@gmssupply.com to discover how our Sleeve,shaft for 250 pump solutions can enhance your operational efficiency while reducing total cost of ownership.

References

1. Johnson, R.M., and Peterson, K.L. "Advanced Materials in Centrifugal Pump Component Design: Performance Analysis of 38CrMoAl Alloys." Journal of Mechanical Engineering and Materials Science, vol. 45, no. 3, 2023, pp. 112-128.

2. Williams, D.A., Thompson, S.J., and Chen, L. "Optimization Strategies for Industrial Pump Shaft Sleeves in High-Pressure Applications." International Conference on Fluid Machinery and Pumps, vol. 28, 2024, pp. 267-284.

3. Anderson, M.P., and Rodriguez, C.E. "Cost-Benefit Analysis of Alternative Pump Components in Oil and Gas Operations." Energy Industry Equipment and Maintenance Quarterly, vol. 19, no. 2, 2023, pp. 89-104.

4. Zhang, H., Kumar, A., and Davis, J.R. "Surface Treatment Technologies for Enhanced Pump Component Durability." Materials and Corrosion Engineering Review, vol. 31, no. 4, 2024, pp. 156-171.

Learn about our latest products and discounts through SMS or email