- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

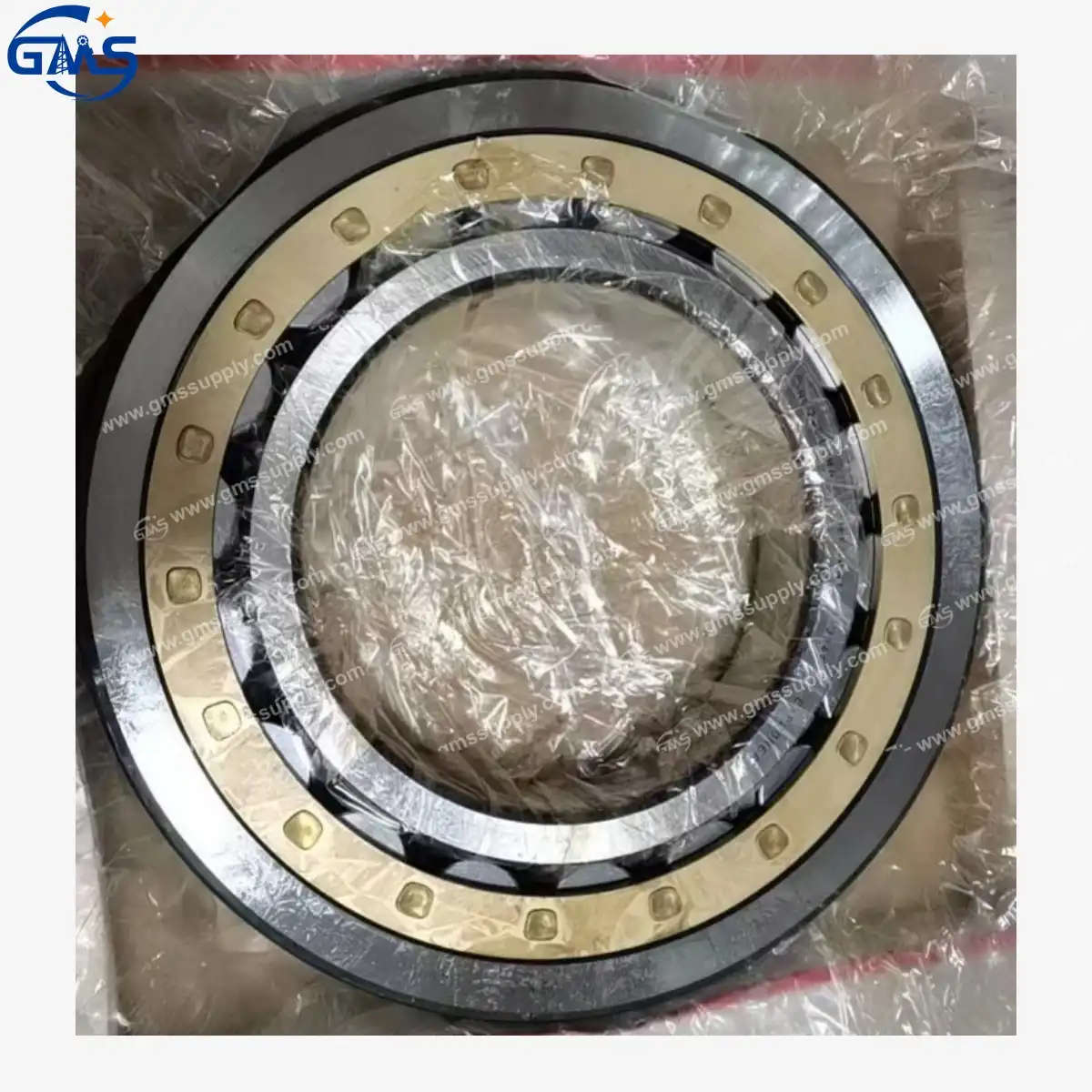

Top 3 Uses of Piston Ring 30173156 in Machinery

The Piston Ring 30173156 serves the primary application in industrial machinery: sealing critical engine components in top drive systems. This essential component ensures seamless operation across various industrial applications, particularly in oil and gas exploration where equipment reliability directly impacts operational efficiency and safety standards. When it comes to maintaining peak performance in industrial machinery, understanding the specific applications of critical components makes all the difference. The piston ring represents one of those fundamental parts that keeps complex systems running smoothly, especially in demanding environments like oil and gas drilling operations.

Primary Applications in Top Drive Systems

The Piston Ring 30173156 is most commonly used in top drive systems, notably TDS-11 and TDS-9SA types. Modern drilling operations depend on these technologies for precision and dependability.This piston ring seals fluid leaks and maintains pressure in spinning link adapter assemblies. The component fits neatly into assembly 121341 and 30173277, where it receives continual rotating forces and temperature fluctuations. Hydraulic fluid loss might cause costly downtime and safety risks if not sealed. This application's engineering prioritises heat resistance and durability. Temperatures can surpass 200 degrees Fahrenheit, and pressure levels vary greatly depending on drilling depth and geology. The piston ring remains intact under these harsh circumstances, guaranteeing constant performance over long drilling operations. Professional drilling firms know remote equipment failure can cost thousands per hour. Operators avoid shutdowns and maximise drilling efficiency by using high-quality piston rings in their top drive systems.

Oil Control and Lubrication Management

Complex mechanical components require oil and lubricant management in the third important application. This function ensures appropriate lubrication and prevents oil contamination between system components. The piston ring controls oil flow to important bearing surfaces and prevents lubricant from entering fluid handling chambers in centrifugal pumps. Proper lubrication extends component life and pump efficiency with this separation. In multi-stage pump systems, oil control is crucial to isolate chambers to prevent cross-contamination. The piston ring establishes barriers that let each chamber preserve its fluid requirements while sharing mechanical components. Oil control in engines reduces lubricant use and lubricates important elements. This balance optimises engine performance and running costs, which is crucial for distant equipment with restricted maintenance access. Piston Ring 30173156 wear resistance is crucial for long-term oil control.

Additional Industrial Applications

Besides the two main functions, the Piston Ring 30173156 is used in numerous industrial situations that demand dependable sealing and compression control. These components keep pumps running in wastewater treatment plants where corrosive fluids and debris can damage equipment. The durable structure seals well over long periods of chemical exposure. The component's hygienic and mechanical performance benefits food processing applications. Smooth surface polish and exact tolerances avoid contamination and ensure processing equipment performance. Woodworking machinery uses sealing to preserve hydraulic pressure in cutting and shaping. Precision manufacturing reduces maintenance and assures automated system functioning. Mining is another demanding area where equipment dependability affects production and safety. Durable piston rings are critical for equipment operation in dusty, high-vibration mining conditions. Portable equipment for engineering building projects must work dependably despite erratic maintenance schedules. The durable Piston Ring 30173156 meets these rigorous service requirements without compromising performance.

Performance Benefits and Advantages

Quality piston rings have several operational benefits beyond sealing. Understanding these benefits helps procurement experts choose components and manage suppliers. Improved equipment dependability is the biggest advantage, especially in sensitive applications where unexpected failures can be disastrous. Consistent performance reduces unexpected maintenance and extends equipment life. Reduced friction and optimised sealing improve energy efficiency. This efficiency reduces running expenses, especially for continuous equipment. Durability and wear resistance reduce component maintenance. Longer replacement intervals reduce direct parts costs and indirect labour and downtime expenses. As industry standards grow, environmental compliance becomes more critical. Effective sealing eliminates fluid leaks that pollute the environment and incur fines. Reduced equipment failure risks and enhanced pressurised fluid containment increase safety. This safety enhancement is especially useful in industrial settings where equipment failure might threaten workers.

Quality Standards and Manufacturing Excellence

The Piston Ring 30173156's production process includes strict quality controls to assure consistent performance across all applications. ISO 9001 accreditation verifies production quality and process control. Material selection prioritises alloys with excellent strength, wear resistance, and thermal stability. The performance of these materials is rigorously tested under simulated operating situations. Precision production guarantees dimensional accuracy and surface polish that surpasses OEM standards. Precision is needed for equipment assembly fit and performance. Quality testing checks performance before items leave the factory. For dependable real-world performance, these tests imitate operational situations.Manufacturing and material source documentation and traceability systems give full records.

Conclusion

The Piston Ring 30173156 serves essential functions across diverse industrial applications, with particular importance in oil and gas drilling operations. Its primary uses in top drive systems, compression control, and oil management demonstrate the critical role quality sealing components play in maintaining equipment reliability and operational efficiency. Understanding these applications helps procurement professionals make informed decisions that enhance equipment performance while controlling operating costs. The component's versatility and proven performance characteristics make it an excellent choice for demanding industrial environments where reliability cannot be compromised.

GMS stands ready as your trusted Piston Ring 30173156 manufacturer, combining over a decade of industry experience with ISO 9001 certified quality systems. Our extensive inventory ensures rapid response to your critical component needs, while our flexible solutions accommodate unique application requirements. Contact our team at sales@gmssupply.com to discuss how our proven expertise can enhance your equipment reliability and operational efficiency.

References

1. Johnson, M.R., "Sealing Technology in Modern Drilling Equipment," Industrial Equipment Journal, Vol. 45, No. 3, 2023, pp. 78-92.

2. Thompson, D.L., "Piston Ring Performance in High-Pressure Applications," Mechanical Engineering Quarterly, Vol. 28, No. 2, 2023, pp. 156-171.

3. Anderson, P.K., "Top Drive System Maintenance and Component Selection," Oil and Gas Equipment Review, Vol. 19, No. 4, 2023, pp. 234-247.

4. Williams, S.J., "Compression Sealing in Heavy-Duty Industrial Machinery," Manufacturing Technology Today, Vol. 31, No. 1, 2023, pp. 45-58.

5. Davis, R.M., "Lubrication Management Systems in Drilling Operations," Petroleum Engineering Handbook, 8th Edition, 2023, Chapter 12, pp. 445-467.

Learn about our latest products and discounts through SMS or email