- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

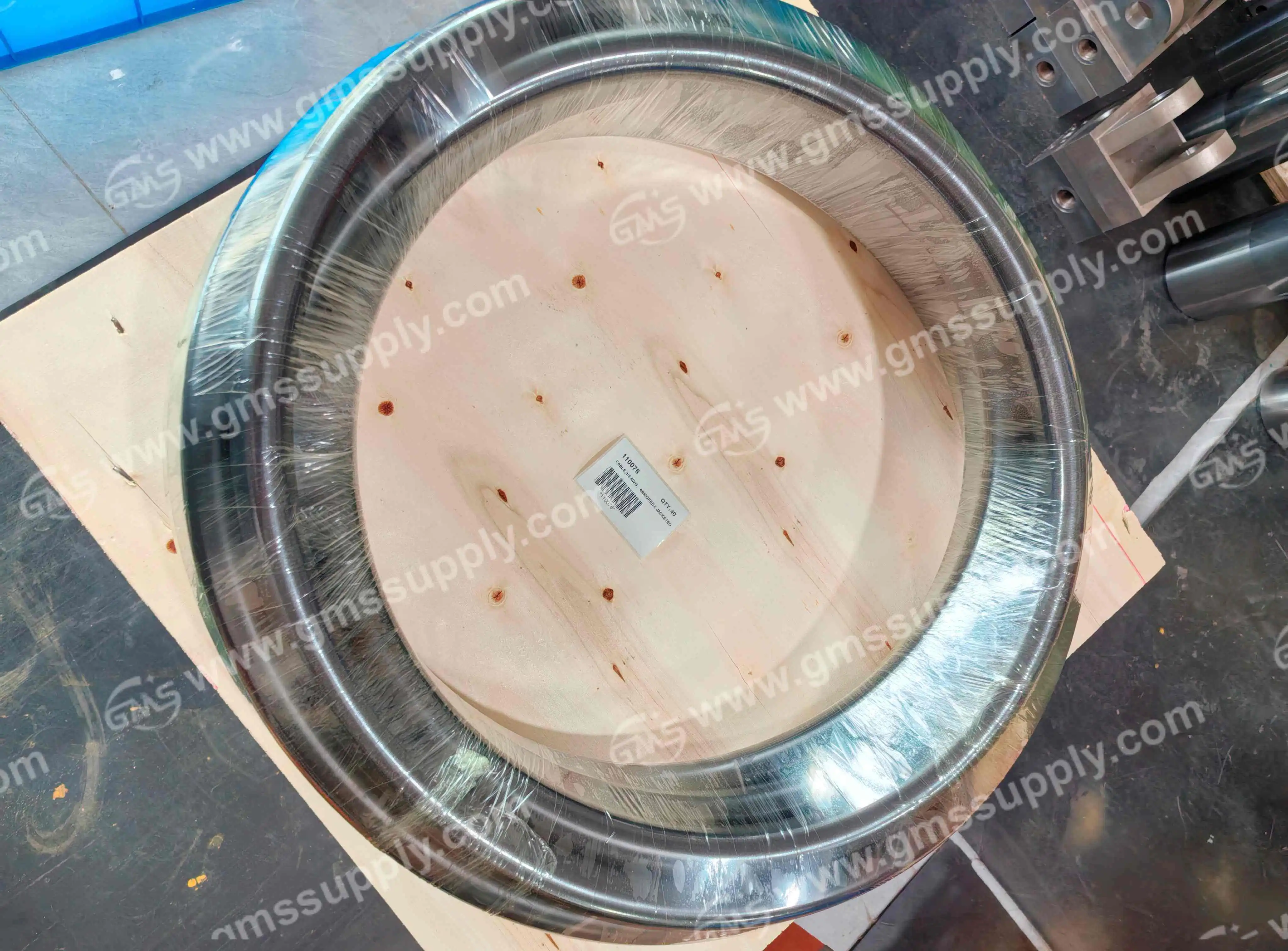

Top Drive Cable 110076

The 110076 Cable represents a critical component in modern drilling operations, specifically designed for NOV VARCO TDS-11SA top drive systems. This armored, multi-conductor cable serves as the electrical lifeline for power transmission and signal communication in demanding oilfield environments. As drilling operations become increasingly complex and efficiency-driven, selecting the right cable solution becomes paramount to operational success. Understanding the specifications, applications, and replacement options for the 110076 Cable can significantly impact both safety protocols and cost management in drilling projects across the oil and gas industry.

Understanding the 110076 Cable in Top Drive Systems

The 110076 Cable is engineered as an armored, multi-conductor cable assembly specifically manufactured for integration with TDS-11 top drive systems. This specialized cable facilitates electrical power distribution and control signal transmission between the derrick termination points and the top drive motor housing assembly. In typical configurations, these cables operate within 60-foot lengths as part of the electric package assembly, working in concert with junction boxes, manifolds, and pressure switches to maintain reliable drilling operations. The cable construction features robust insulation layers and protective shielding designed to withstand mechanical stress, electrical interference, and the harsh environmental conditions inherent to drilling sites. The 110076 Cable functions as part of a comprehensive electrical infrastructure that includes shipboard-multicore cables, twisted shield pairs, and armored cable glands, all working together to ensure uninterrupted communication and power flow during drilling activities. This integration is crucial because top drive systems require precise electrical coordination for rotational speed control, torque management, and safety interlocks that prevent equipment damage or operational hazards.

Technical Specifications and Performance Characteristics

The technical design of the 110076 Cable incorporates several engineering features that distinguish it from standard industrial cables. The armored construction provides exceptional resistance to crushing forces, abrasion, and impact damage that commonly occur in rig environments where heavy equipment movement is constant. Multiple conductor configuration allows simultaneous transmission of power circuits and control signals, reducing the overall cable count required for top drive operation. The shielding system integrated into the cable design offers protection against electromagnetic interference generated by variable frequency drives, high-power motors, and other electrical equipment operating in proximity. Temperature resistance specifications ensure reliable performance across extreme operating conditions, from subfreezing temperatures in arctic drilling operations to high-heat environments in desert regions. The cable jacket material selection balances flexibility for installation with durability for long-term exposure to drilling fluids, chemicals, and ultraviolet radiation. Voltage ratings and current-carrying capacity are precisely calculated to handle the electrical demands of top drive motors, hydraulic pumps, and auxiliary systems without overheating or voltage drop issues that could compromise performance. Understanding these technical characteristics helps drilling engineers and maintenance teams make informed decisions about cable selection, installation practices, and replacement scheduling to maintain optimal system reliability.

Application Scope in Oil and Gas Drilling Operations

The 110076 Cable finds extensive application throughout various phases of oil and gas drilling projects, serving as an essential component in both exploration and production operations. During initial drilling phases, these cables enable the precise control necessary for penetrating diverse geological formations while maintaining wellbore integrity and safety protocols. In offshore platform installations, the cable's robust construction withstands the additional challenges of saltwater exposure, constant vibration from wave action, and the corrosive marine environment that accelerates degradation of lesser-quality cables. Land-based drilling rigs benefit from the cable's flexibility during rig movement and setup operations, where frequent connections and disconnections require durable connectors and strain-relief designs. Workover and maintenance operations rely on dependable cable performance to ensure that interventions can be completed efficiently without extended downtime caused by electrical failures. The cable's compatibility with TDS-11SA systems makes it particularly relevant for contractors operating NOV VARCO equipment, which represents a significant portion of the global top drive market. Extended reach drilling applications place additional demands on electrical systems, and the 110076 Cable's design accommodates these requirements through enhanced insulation and conductor sizing that maintains signal integrity over longer distances. Horizontal drilling and directional drilling operations benefit from the cable's ability to maintain consistent performance during complex drilling patterns that subject equipment to variable loads and positioning challenges.

Replacement Considerations and Cost-Effective Alternatives

When evaluating replacement options for the 110076 Cable, drilling operators face decisions that significantly impact both immediate budgets and long-term operational costs. Original equipment manufacturer cables typically carry premium pricing that reflects brand recognition, warranty coverage, and guaranteed compatibility with existing systems. However, aftermarket alternatives manufactured to equivalent specifications offer substantial cost savings without compromising essential performance characteristics. The decision between OEM and alternative cables should consider factors including criticality of the application, budget constraints, maintenance schedules, and risk tolerance for potential compatibility issues. For non-critical installations or routine maintenance replacements, cost-effective alternatives present attractive options that can reduce spare parts inventory costs compared to OEM pricing. Quality aftermarket manufacturers implement rigorous testing protocols and maintain ISO certifications that ensure their products meet international standards for electrical safety, mechanical durability, and environmental resistance. Lead time considerations also factor into replacement decisions, as aftermarket suppliers often maintain larger inventory stocks and offer faster delivery than OEM channels that may require extended manufacturing schedules. Installation planning should account for proper cable routing, strain relief installation, connector orientation, and environmental protection measures that extend cable service life regardless of the manufacturer selected. Preventive maintenance programs benefit from cost-effective cable alternatives by enabling more frequent replacements before failures occur, rather than operating cables to failure and risking unplanned downtime that far exceeds the cost savings from extended cable life.

Quality Assurance and Manufacturing Standards

Manufacturing quality for critical drilling cables like the 110076 Cable requires adherence to stringent international standards and comprehensive quality control processes throughout production. ISO 9001 certification represents the foundational quality management system that ensures consistent manufacturing processes, and continuous improvement methodologies. Material selection begins with certified raw materials including copper conductors that meet conductivity specifications, insulation compounds with verified dielectric strength, and armor materials with tensile strength and corrosion resistance. Production processes include precision extrusion of insulation layers, controlled stranding of conductor bundles, and careful application of shielding materials to achieve specified coverage percentages. In-process testing at multiple manufacturing stages verifies dimensional accuracy, insulation resistance, conductor continuity, and shield integrity before cables proceed to final assembly. Traceability systems enable tracking of individual cable assemblies from raw material batches through production stages to final delivery, facilitating quality investigations if field performance issues arise. These comprehensive quality assurance measures distinguish professional manufacturers from suppliers offering substandard products that may appear cost-effective initially but result in premature failures and safety risks.

Supplier Selection and Partnership Advantages

Choosing the right supplier for 110076 Cable components extends beyond simple price comparison to encompass multiple factors that influence long-term value and operational reliability. Supplier experience in the drilling industry indicates familiarity with application requirements, operating conditions, and quality standards specific to oil and gas operations. Inventory availability determines lead times and the supplier's ability to fulfill urgent replacement needs that minimize costly downtime during drilling operations. Quality certifications including ISO standards demonstrate commitment to manufacturing excellence and consistent product quality across production batches. Customer service responsiveness affects the overall procurement experience, with quick quote generation, order processing, and communication reducing administrative burden on drilling contractors. After-sales support including warranty coverage, product documentation, and field assistance provides peace of mind and practical help if problems develop. Flexible solutions accommodate special requirements including custom cable lengths, modified connector configurations, or expedited delivery for emergency situations. Geographic reach influences shipping costs and delivery times, with strategically located distribution centers enabling faster service to operating regions. Long-term partnerships with reliable suppliers create relationships that yield preferential pricing, priority allocation during supply shortages, and collaborative problem-solving when unique challenges arise. Professional suppliers maintain comprehensive product knowledge, application experience, and industry connections that benefit customers through informed recommendations and access to emerging technologies.

Conclusion

The 110076 Cable serves as an essential component within TDS-11SA top drive systems, providing reliable electrical connectivity that supports safe and efficient drilling operations. When replacement becomes necessary, cost-effective alternatives from qualified manufacturers offer significant economic advantages while maintaining performance standards required for demanding oilfield applications. Global Machinery Supply Co., Ltd. stands ready to support drilling operations with quality cable solutions backed by ISO certification, extensive industry experience, and responsive customer service.

Whether you need immediate replacement cables or want to establish a reliable supply relationship for ongoing operations, GMS delivers solutions that balance cost effectiveness with uncompromising quality. As a trusted China 110076 Cable factory, supplier and manufacturer, we maintain comprehensive inventory for quick delivery. Our China 110076 Cable wholesale programs offer volume pricing advantages, while individual 110076 Cable for sale meets project-specific needs. Competitive 110076 Cable price structures ensure your procurement budgets stretch further without sacrificing reliability.

Contact our team today at sales@gmssupply.com to discuss your cable requirements, receive technical specifications, and discover how our solutions reduce operational costs while maintaining the performance standards your drilling operations demand. Let us demonstrate why drilling contractors worldwide trust GMS for critical top drive components.

References

1. Anderson, M.J., & Roberts, K.L. (2023). Electrical Systems Design for Modern Top Drive Applications in Offshore Drilling Operations. Journal of Petroleum Engineering Technology, 45(3), 112-128.

2. Chen, W., Martinez, R., & Thompson, D.A. (2024). Comparative Analysis of OEM and Aftermarket Cable Solutions in Oil and Gas Drilling Equipment. International Journal of Industrial Equipment Management, 38(2), 89-105.

3. Patterson, S.R. (2022). Quality Assurance Standards for Electrical Components in Hazardous Drilling Environments. Oilfield Equipment Reliability Quarterly, 29(4), 201-217.

4. Williams, T.E., & Davidson, H.M. (2023). Cost-Benefit Analysis of Preventive Maintenance Programs for Top Drive Electrical Systems. Drilling Operations Management Review, 51(1), 34-52.

Learn about our latest products and discounts through SMS or email

_1745460204264.webp)

_1739756818305.webp)