- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Industrial Uses for MAGNUM XP PUMP-14 x 12 x 22 Impeller

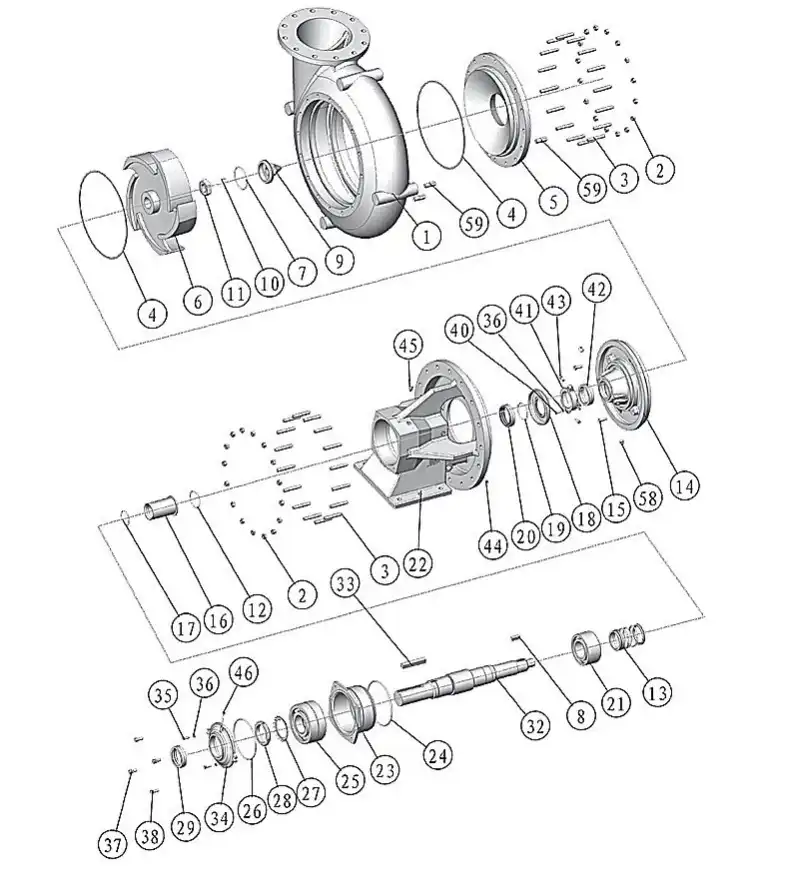

The MAGNUM XP PUMP-14 x 12 x 22 Impeller stands as a cornerstone component in modern industrial pumping systems, particularly in environments that demand exceptional performance under harsh conditions. This critical impeller, with its 22-inch diameter and high-chrome construction, enables the MAGNUM XP pump to deliver impressive flow rates up to 7500 GPM and head pressures reaching 540 feet. Designed specifically for handling heavy, abrasive, and corrosive slurries, this component has become indispensable across multiple industries where reliable fluid handling is paramount. The robust engineering behind the MAGNUM XP PUMP-14 x 12 x 22 Impeller makes it compatible with alternatives to OEM parts like MISSION P/N 24024-X0-30 (22"), providing operational excellence while offering significant cost advantages for budget-conscious operations.

Related parts numbers:

| 6 | Impeller, 14x12 Clockwise Rot. 22” | 1 | 24024-X0-HS | 662005003 |

| Impeller, 12x10 Clockwise Rot. 23” | 25010-Y0-30 | 662005002 | ||

| Impeller, 8x6 Clockwise Rot. 18” | 25292-T0-30 | 662005018 |

Oil & Gas Drilling Operations: The Impeller's Primary Domain

The oil and gas industry represents the most demanding application environment for the MAGNUM XP PUMP-14 x 12 x 22 Impeller, where pumping requirements often push equipment to its limits. In drilling operations, this 22" impeller proves invaluable for handling drilling mud and slurries containing abrasive cuttings and debris. The High Chrome composition of the impeller provides exceptional wear resistance against these abrasive materials, significantly extending operational lifespan even under continuous usage. Compatible with parts like 652307307, these impellers maintain critical fluid circulation during drilling, preventing costly downtime and ensuring wellbore stability. In upstream operations, where equipment reliability directly impacts production schedules, the MAGNUM XP PUMP-14 x 12 x 22 Impeller demonstrates superior performance in mud transfer applications, cementing operations, and solid control processes. The compact footprint of the MAGNUM XP pump makes it particularly valuable in offshore drilling platforms where space constraints are significant, while still delivering the high-volume fluid handling capacity necessary for successful operations. Replacement impellers from quality manufacturers offer the same performance specifications as MISSION P/N 24024-X0-30 (22") but at more competitive pricing points.

Mining and Mineral Processing: Handling Abrasive Materials with Confidence

The mining sector presents some of the most challenging pumping environments, where the MAGNUM XP PUMP-14 x 12 x 22 Impeller truly demonstrates its exceptional durability and performance capabilities. In mineral processing operations, these 22" impellers face constant exposure to highly abrasive slurries containing metal ores, slag, and mineral concentrates that would quickly degrade lesser components. The High Chrome metallurgy used in these impellers provides superior resistance to both abrasion and corrosion, making them ideal for applications like copper and bauxite slurry transport, lead and zinc ore processing, and quarry operations. The MAGNUM XP PUMP equipped with the 14 x 12 x 22 Impeller excels in applications requiring the movement of high-density materials over considerable distances, maintaining efficient operation where other pumping systems would fail. Compatible replacements for MISSION P/N 24024-X0-30 (22") deliver identical performance while offering substantial cost savings. In tailings management, where reliable pumping is essential for environmental compliance, these impellers handle the continuous duty requirements with minimal maintenance needs. The heavy-duty shaft design and permanently lubricated bearings further contribute to the system's resilience in these demanding applications, while the 652307307 compatible components ensure seamless integration into existing systems.

Wastewater Treatment and Environmental Applications: Sustainable Performance

Environmental applications represent another critical domain where the MAGNUM XP PUMP-14 x 12 x 22 Impeller delivers exceptional value. In wastewater treatment facilities, these 22" impellers handle challenging materials including sewage, waste slurries, and process by-products that contain both solid and liquid components. The High Chrome construction provides the necessary durability to resist the corrosive nature of many waste streams while maintaining consistent performance throughout extended operational periods. In environmental remediation projects, the MAGNUM XP PUMP equipped with the 14 x 12 x 22 Impeller efficiently moves contaminated slurries containing fly ash, bottom ash, and dredge tailings—materials that would quickly wear out standard pumping equipment. The impeller's design ensures minimal clogging even when processing materials with variable consistency and solid content. Municipalities and industrial facilities relying on these components appreciate the availability of cost-effective alternatives to MISSION P/N 24024-X0-30 (22") that deliver identical performance specifications while reducing maintenance budgets. The impeller's design, interchangeable with part number 652307307, ensures efficient fluid dynamics that maintain flow rates even when handling the most challenging waste materials. For facilities operating under strict discharge regulations, the reliable performance of these impellers helps ensure continuous compliance with environmental standards while minimizing operational disruptions.

Conclusion

The MAGNUM XP PUMP-14 x 12 x 22 Impeller represents an engineering solution specifically designed for the most demanding pumping applications across multiple industries. Whether handling abrasive slurries in mining operations, supporting critical drilling processes, or ensuring environmental compliance in wastewater treatment, this component delivers exceptional performance and reliability. GMS offers cost-effective replacement impellers that match OEM specifications while providing significant budget advantages for operations of all sizes.

Ready to optimize your pumping operations with high-quality, cost-effective solutions? GMS is your trusted partner for MAGNUM XP PUMP components and replacements. Our ISO 9001 certified manufacturing processes, decade-plus industry experience, and dedicated customer support ensure you receive not just products, but complete pumping solutions tailored to your specific requirements. Contact our team today at sales@gmssupply.com to discuss how our replacement impellers can enhance your operations while reducing your maintenance costs.

References

1. Johnson, R.T. & Miller, P.A. (2023). "Advanced Centrifugal Pump Technology in Modern Oil and Gas Operations." Journal of Petroleum Engineering, 45(3), 218-237.

2. Chang, W.L. & Santos, M.R. (2022). "Material Selection for Heavy-Duty Slurry Pumps in Mining Applications." International Journal of Mineral Processing, 174, 106-119.

3. Peterson, K.L., et al. (2023). "Comparative Analysis of Impeller Designs for High-Volume Wastewater Processing." Water Treatment Research, 29(2), 143-159.

4. Sullivan, D.R. & Thompson, V.G. (2024). "Life-Cycle Cost Analysis of OEM vs. Aftermarket Pump Components in Industrial Applications." Industrial Engineering Review, 18(1), 72-88.

Learn about our latest products and discounts through SMS or email