- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

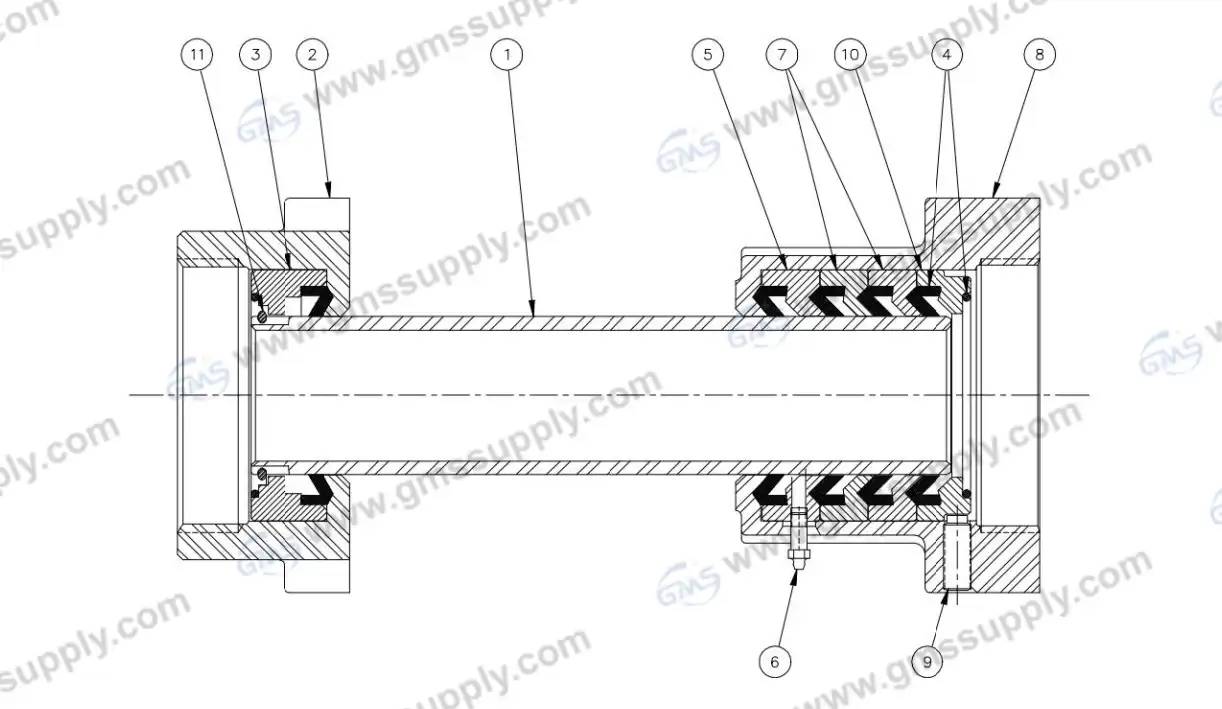

Washpipe Assembly AY10031 Maintenance Tips for Drilling Operations GMS Supply

Proper maintenance of the Washpipe Assembly AY10031 is essential for optimizing drilling efficiency and reducing operational downtime in top drive systems. This critical component serves as the conduit for drilling fluids in Canrig top drive models including 8035, 8050, and 6027, where it plays an indispensable role in facilitating smooth drilling operations. Understanding comprehensive maintenance strategies ensures that drilling contractors can maximize the service life of their equipment while maintaining consistent performance under demanding conditions. Effective maintenance practices not only prevent costly failures but also contribute to safer operations and improved overall drilling productivity across various applications in the oil and gas industry.

Understanding the Critical Role of Washpipe Assembly AY10031 in Top Drive Systems

The Washpipe Assembly AY10031 functions as a fundamental component within top drive drilling systems, serving multiple essential purposes that directly impact operational efficiency. The assembly rotates in conjunction with the drill pipe while simultaneously providing critical lubrication and sealing support to prevent fluid leakage. In Canrig top drive systems, particularly models 8035, 8050, and 6027, the Washpipe Assembly AY10031 integrates seamlessly with the overall drilling architecture to ensure continuous fluid delivery throughout extended drilling operations. The dynamic sealing arrangement within the assembly must withstand extreme conditions including high temperatures, abrasive drilling mud, and constant rotational stresses that can lead to premature wear if not properly maintained. Modern top drive systems rely heavily on the integrity of this component, as any failure can result in significant downtime requiring the entire bottom hole assembly to be tripped back to the surface for repairs. Understanding the operational demands placed on the Washpipe Assembly AY10031 helps drilling teams appreciate why implementing rigorous maintenance protocols is not merely recommended but essential for sustained operational success and cost management.

Essential Maintenance Practices for Extending Washpipe Assembly AY10031 Service Life

Implementing systematic maintenance practices significantly extends the operational life of the Washpipe Assembly AY10031 and prevents unexpected failures during critical drilling phases. Regular inspection of the packing seals represents the cornerstone of effective maintenance, as these elastomeric components experience the most severe wear due to constant contact with the rotating washpipe surface under high pressure and temperature conditions. Operators should establish a routine inspection schedule that examines seal integrity, checking for signs of heat damage, abrasive wear, or material degradation that could compromise sealing performance. Proper lubrication management plays an equally vital role in maintenance protocols, with many modern washpipe assemblies incorporating auto-lubricating systems that deliver pressurized lubricant to the sealed region between rotary seals, effectively isolating the pressure-retaining seal from abrasive drilling fluids. Drilling teams should monitor lubricant levels consistently and ensure that the correct grade of lubricant is used according to manufacturer specifications to maintain optimal seal performance. Surface condition monitoring of the washpipe itself is another critical maintenance element, as the smooth external surface must remain free from scoring, pitting, or other damage that could compromise seal contact and lead to premature seal failure. Implementing vibration monitoring can provide early warning signs of bearing wear or alignment issues that might affect the Washpipe Assembly AY10031 performance before catastrophic failure occurs. Temperature monitoring during operations helps identify excessive heat generation that often indicates seal wear or inadequate cooling, allowing operators to take corrective action before complete seal failure forces unplanned downtime.

Identifying Common Failure Modes and Implementing Preventive Measures for Washpipe Assembly AY10031

Understanding common failure modes enables drilling teams to implement targeted preventive measures that significantly reduce unexpected downtime associated with the Washpipe Assembly AY10031. Seal wear represents the most frequent failure mode, typically manifesting as gradual loss of sealing effectiveness due to abrasive particle ingestion, thermal degradation, or mechanical fatigue from repeated pressure cycles and rotational stresses. Excessive heat generation from high surface velocities or inadequate cooling can cause rapid seal deterioration, with operators often observing visible heat damage or material hardening before complete seal failure occurs. Washpipe surface damage including scoring or pitting creates leak paths that compromise seal contact and accelerate seal wear, often resulting from abrasive particle contamination in drilling fluids or improper handling during maintenance procedures. Alignment issues stemming from bearing wear or improper installation can introduce runout that places uneven loads on seals and reduces their effective service life through accelerated localized wear patterns. Preventive measures should include implementing robust filtration systems to minimize abrasive particle content in drilling fluids, thereby reducing seal wear and extending assembly life. Establishing strict handling protocols during maintenance operations protects the critical washpipe surface from damage that could compromise subsequent seal performance. Regular bearing inspections and replacements according to manufacturer recommendations prevent alignment issues before they cause secondary damage to seals and other components. Implementing condition monitoring systems that track key performance indicators such as seal temperature, lubricant consumption, and pressure variations provides early warning of developing issues before they progress to complete failure requiring extended downtime.

Strategic Replacement Planning and Cost-Effective Sourcing for Washpipe Assembly AY10031

Developing a strategic replacement plan for the Washpipe Assembly AY10031 optimizes operational continuity while managing maintenance costs effectively throughout the equipment lifecycle. Maintaining adequate spare parts inventory including complete washpipe assemblies, seal kits, and individual components ensures that replacement parts are readily available when scheduled or emergency maintenance becomes necessary. Forward-thinking operators recognize that sourcing high-quality replacement components from reliable suppliers delivers superior value compared to purchasing lowest-cost alternatives that may compromise on material quality or manufacturing precision. Alternative replacement parts manufactured to OEM specifications offer compelling advantages including significant cost savings without sacrificing performance reliability, making them particularly attractive for budget-conscious operations or non-critical component replacements. GMS provides Washpipe Assembly AY10031 replacement components that deliver equivalent performance to original parts while offering price advantages that improve overall maintenance cost management. ISO 9001 certification ensures that replacement components meet stringent international quality standards through controlled manufacturing processes from raw materials through finished products. The replacement decision should balance immediate cost considerations against long-term performance expectations and potential downtime costs associated with premature component failure. Establishing relationships with suppliers who maintain large inventory stocks and offer short lead times minimizes operational risk by ensuring rapid component availability when urgent replacements become necessary. Comprehensive after-sales support including technical assistance and warranty coverage provides additional value that extends beyond the initial purchase price, offering operators confidence in their component sourcing decisions.

Conclusion

Effective maintenance of the Washpipe Assembly AY10031 directly impacts drilling operation efficiency, safety, and cost management through extended component life and reduced unplanned downtime. Implementing systematic inspection protocols, optimizing operational parameters, and sourcing quality replacement components from reliable suppliers creates a comprehensive maintenance strategy that maximizes return on investment while maintaining operational excellence throughout demanding drilling campaigns.

Ready to optimize your drilling operations with cost-effective, high-quality replacement components? GMS stands as your trusted China Washpipe Assembly AY10031 manufacturer, offering superior alternatives that deliver OEM-equivalent performance at significantly reduced costs. As a leading China Washpipe Assembly AY10031 supplier and factory, we maintain extensive inventory ensuring rapid delivery for your urgent operational needs. Our Washpipe Assembly AY10031 for sale comes with ISO 9001 certification guaranteeing consistent quality through every production stage. Whether you're seeking competitive Washpipe Assembly AY10031 price quotes or exploring China Washpipe Assembly AY10031 wholesale opportunities for fleet-wide requirements, our experienced team provides responsive support typically within two hours. With over fifteen years of specialized experience in drilling machinery supply, GMS combines deep industry knowledge with flexible solutions tailored to your specific operational challenges. Contact our sales team at sales@gmssupply.com today to discuss how our reliable products and dedicated service can reduce your operating costs while maintaining the performance standards your operations demand. Let GMS become your strategic partner in achieving operational excellence through quality components and exceptional customer support.

References

1. Kubala, Z. (2008). Mechanical seal washpipe assemblies for high-pressure drilling applications. Journal of Petroleum Technology, 60(4), 78-84.

2. Martin, W.D. (2010). Auto-lubricating systems for rotary drilling equipment: Design considerations and operational benefits. SPE Drilling & Completion, 25(2), 156-163.

3. Thompson, R.L. & Anderson, K.M. (2015). Extending service life of top drive washpipe assemblies through optimized maintenance practices. International Journal of Oil, Gas and Coal Technology, 9(3), 312-328.

4. Chen, H. & Rodriguez, P. (2018). Failure mode analysis and preventive strategies for washpipe assemblies in extended reach drilling operations. Petroleum Science and Technology, 36(8), 627-634.

5. Williams, J.S. (2021). Economic evaluation of OEM versus aftermarket components in oil and gas drilling operations. Journal of Energy Resources Technology, 143(5), 052801-1 to 052801-9.

Learn about our latest products and discounts through SMS or email