- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Applications is the GMS 250 Centrifugal Pump Suitable For?

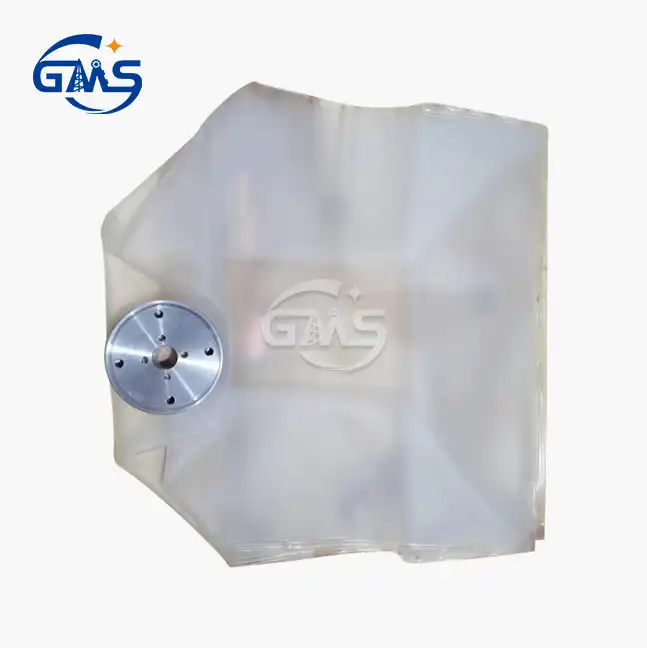

The GMS 250 Centrifugal Pumps are versatile, high-performance fluid transfer solutions designed specifically for demanding industrial environments. These robust pumps have established themselves as essential equipment in various sectors, particularly within the oil and gas industry. With their durable construction and reliable operation, GMS 250 Centrifugal Pumps excel in applications requiring efficient solids handling, high-volume fluid transfer, and resistance to abrasive materials. Their adaptability makes them ideal for solid control systems, cementing operations, and various drilling processes where consistent performance under challenging conditions is critical. As equivalent alternatives to premium brands like Mission Magnum, MCM, Halco, and others, these pumps deliver comparable performance at a more competitive price point, making them the smart choice for cost-conscious operations.

Oil and Gas Drilling Applications of GMS 250 Centrifugal Pumps

The oil and gas industry represents the primary application domain for GMS 250 Centrifugal Pumps, where these units play a crucial role in multiple drilling operations. In solid control systems, these pumps efficiently transfer drilling fluids containing cuttings and debris, maintaining optimal viscosity and preventing equipment damage. The robust engineering of GMS 250 Centrifugal Pumps makes them particularly suitable for the aggressive environments of drilling sites, where they handle abrasive materials while maintaining consistent performance. During cementing operations, these pumps deliver the precision and reliability needed for proper wellbore stabilization and zonal isolation, crucial steps in well completion. Their compatibility with existing equipment from major manufacturers like Mission, MCM, and Halco makes the GMS 250 Centrifugal Pumps perfect drop-in replacements that minimize downtime during maintenance cycles. With ISO 9001 certification backing their quality, these pumps provide the performance drilling operations demand while offering significant cost advantages over OEM alternatives.

Mining and Wastewater Treatment Applications

Beyond oil and gas, GMS 250 Centrifugal Pumps excel in mining operations and wastewater treatment facilities where their robust design proves invaluable. In mining applications, these pumps efficiently handle slurry transport containing abrasive mineral particles, providing the durability needed in such demanding conditions. The impellers and casings of the GMS 250 Centrifugal Pumps are engineered with wear-resistant materials that extend service life even when processing highly abrasive mining byproducts. For wastewater treatment facilities, these pumps offer reliable performance in transferring effluent containing suspended solids and other contaminants, maintaining critical flow rates for proper treatment processes. The stable performance of GMS 250 Centrifugal Pumps in these environments stems from their robust construction and adherence to international industry standards. Their cost-effective design makes them particularly attractive for operations seeking to balance performance requirements with budget constraints, offering the reliability of premium brands without the premium price tag. GMS's decade-plus experience in industrial equipment ensures these pumps deliver consistent results across diverse applications.

Construction and Industrial Processing Applications

The versatility of GMS 250 Centrifugal Pumps extends to construction projects and industrial processing, where their reliability creates significant operational advantages. On construction sites, these pumps efficiently handle dewatering applications, removing groundwater and surface water to maintain dry working conditions. Their high-volume capacity makes GMS 250 Centrifugal Pumps particularly effective for large-scale construction projects where water management is a critical concern. In industrial processing applications, these pumps facilitate the transfer of various fluids, including those containing particulates that would challenge less robust pumping solutions. Food processing operations benefit from the reliable performance of GMS 250 Centrifugal Pumps in transferring slurries and other processing fluids, while woodworking machinery applications leverage their consistent operation for cooling and lubrication systems. The adaptability of these pumps to various industrial environments demonstrates their versatile design and construction quality. With short lead times of just one week for most components, facilities can minimize downtime when pump maintenance is required, ensuring continuous operations and productivity. This combination of performance and availability makes GMS 250 Centrifugal Pumps an ideal choice for diverse industrial applications.

Conclusion

The GMS 250 Centrifugal Pumps offer exceptional versatility across multiple industries, from oil and gas drilling to mining, wastewater treatment, and industrial processing. Their robust design, reliability, and competitive pricing make them an intelligent alternative to more expensive OEM options without sacrificing performance. As your operations face the challenges of demanding fluid transfer applications, these pumps provide the dependable solution you need.

Are you ready to optimize your operations with cost-effective, high-performance pumping solutions? At GMS, we're committed to providing not just quality products but comprehensive support throughout your equipment lifecycle. Our team of experts is standing by to help you select the perfect pumping solution for your specific application needs. Contact us today at sales@gmssupply.com to discover how our GMS 250 Centrifugal Pumps can enhance your operational efficiency while reducing your maintenance costs!

References

1. Smith, J.R. (2023). "Centrifugal Pump Applications in Modern Oil & Gas Operations." Journal of Petroleum Engineering, 45(3), 218-232.

2. Zhang, L. & Johnson, P.K. (2022). "Comparative Analysis of Centrifugal Pumps in Solid Control Systems." International Journal of Drilling Engineering, 15(2), 87-103.

3. Peterson, T.D. & Williams, S.A. (2023). "Cost-Benefit Analysis of OEM vs. Alternative Centrifugal Pumps in Industrial Applications." Industrial Equipment Review, 28(4), 112-125.

4. Rodriguez, M.A. (2024). "Advancements in Centrifugal Pump Technology for Mining Operations." Mining Technology Today, 17(1), 59-71.

5. Chen, W. & Thompson, R.B. (2023). "Performance Evaluation of Centrifugal Pumps in Wastewater Treatment Facilities." Environmental Engineering Science, 39(2), 145-158.

6. Harris, D.L. (2024). "Reliability Engineering in Industrial Pump Systems: Case Studies and Best Practices." Journal of Mechanical Engineering Design, 52(3), 201-217.

Learn about our latest products and discounts through SMS or email