- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are shoulder screws used for?

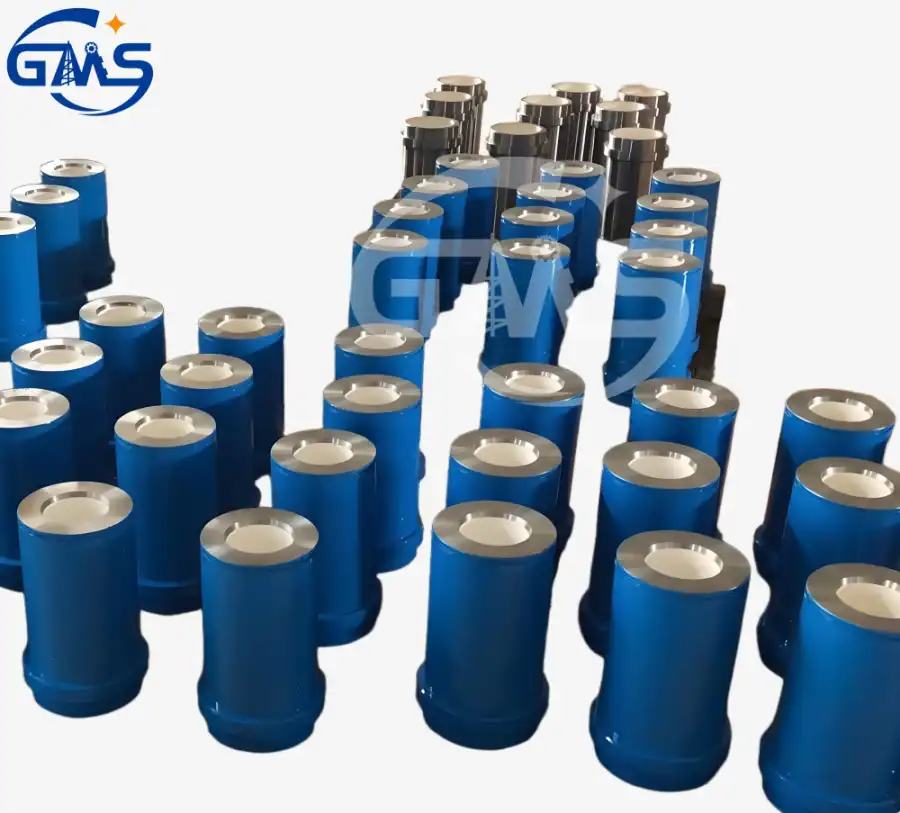

Shoulder screws are precision fasteners designed to perform critical functions in industrial applications where standard fasteners fall short. Unlike conventional screws that simply hold parts together, these specialized components feature a smooth, unthreaded shoulder section that enables rotation, precise alignment, and controlled movement in mechanical assemblies. The 914-14-0 Screw Shoulder, for instance, represents a crucial component in oil and gas drilling operations, specifically engineered for Canrig top drive systems where reliability and precision are non-negotiable.

Understanding the Core Functions of Shoulder Screws

Shoulder screws fulfill multiple specialized roles that conventional fasteners cannot adequately address. Their unique three-part construction consisting of a head, an unthreaded shoulder, and a threaded section allows them to function as both fasteners and mechanical components. The shoulder portion acts as a precision-machined shaft that accommodates bearings, bushings, and other rotating or sliding elements while maintaining exact spacing between components. In oil and gas drilling applications, components like the 914-14-0 Screw Shoulder must withstand extreme loads, constant vibration, and harsh environmental conditions while maintaining precise alignment of critical assemblies. The smooth shoulder surface provides a low-friction bearing surface that enables controlled motion without wear or binding, making these fasteners indispensable in applications requiring pivot points, axles for rotating parts, or guides for linear motion. Industries rely on shoulder screws when standard bolts would create excessive friction, allow unwanted movement, or fail to maintain the tight tolerances necessary for proper equipment function.

Applications in Oil and Gas Drilling Operations

The oil and gas drilling sector represents one of the most demanding environments for mechanical fasteners, where components must perform reliably under extraordinary stress. Shoulder screws play a vital role in top drive systems, which are sophisticated drilling mechanisms that rotate the drill string from the surface. The 914-14-0 Screw Shoulder specifically serves in Canrig top drive models including the 8050, 8035, and 6027AC, where it maintains critical alignment and connection integrity during drilling operations. These precision fasteners must handle shear loads generated by the rotational forces of drilling while simultaneously maintaining exact positioning of drive components. The unthreaded shoulder section acts as a precise guide that prevents lateral movement and ensures that rotating assemblies maintain proper alignment even under extreme torque conditions. During drilling operations that can extend thousands of feet below the surface, any misalignment or component failure can result in costly downtime and safety hazards, making the reliability of components like the 914-14-0 Screw Shoulder absolutely essential. The fastener's ability to serve both as a structural connector and a precision alignment element makes it irreplaceable in these high-stakes applications where equipment performance directly impacts operational efficiency and safety.

Pivot Points and Rotational Applications

One of the primary functions of shoulder screws involves creating controlled pivot points and rotational assemblies in mechanical systems. The precision-ground shoulder section provides an ideal bearing surface for components that must rotate freely while remaining securely positioned. In industrial machinery, shoulder screws serve as axles for pulleys, gears, and sprockets that require moderate-speed rotation with minimal friction and wear. The shoulder diameter is machined to extremely tight tolerances, typically within thousandths of an inch, ensuring that bearings or bushings mounted on the shoulder maintain consistent clearance for smooth operation. When properly installed, the threaded portion secures the screw firmly in place while the shoulder extends beyond the mounting surface to create a functional shaft. This dual-purpose design eliminates the need for separate shaft components and reduces assembly complexity. In top drive systems where the 914-14-0 Screw Shoulder operates, rotating mechanisms must function flawlessly under continuous operation, and the precision shoulder provides the necessary stability and alignment. The bearing surfaces on shoulder screws are often harder than standard fastener materials, providing resistance to wear even after millions of rotational cycles, which is critical in applications where component replacement would require extensive equipment downtime.

Alignment and Precision Spacing Functions

Maintaining exact component spacing and alignment represents another crucial application for shoulder screws in precision assemblies. The shoulder section acts as a physical spacer that establishes and maintains specific distances between parts, ensuring that mechanical assemblies function with the intended clearances and alignments. In punch and die mechanisms, shoulder screws often called stripper bolts in these applications create linear guides that ensure die halves open and close along precisely aligned paths. The 914-14-0 Screw Shoulder fulfills similar alignment functions in Canrig top drive systems, where multiple components must work in perfect coordination to transmit rotational power efficiently. Unlike standard fasteners whose primary function ends once tightened, the shoulder screw continues to perform a structural role by maintaining the geometric relationships between parts throughout operation. Engineers specify shoulder screws when assembly tolerances are critical and when components must remain positioned accurately despite vibration, thermal expansion, or operational stresses. The precision-ground shoulder diameter ensures repeatable positioning across multiple assembly and disassembly cycles, which is valuable in maintenance situations where equipment must be serviced and reassembled to original specifications.

Bearing and Bushing Support Applications

Shoulder screws provide ideal mounting solutions for bearings and bushings where smooth rotation under load is required. The shoulder section is specifically designed to support the inner race of ball bearings or the bore of bushings, creating simple but effective rotating assemblies. When a bearing is mounted on a shoulder screw, the inner race remains fixed against rotation while the outer race spins freely, effectively creating a cam follower or rolling element. This application is widespread in machinery where guided motion or load-bearing rotation is needed without the complexity of dedicated shaft assemblies. The precision tolerances of components like the 914-14-0 Screw Shoulder ensure proper fit with bearing specifications, preventing both excessive play that would cause vibration and interference that would create friction and heat. In drilling equipment, bearing-mounted shoulder screws must handle substantial radial loads while maintaining smooth operation even when contaminated with drilling fluids or subjected to temperature variations. The hardened shoulder surface resists wear from constant bearing contact, extending service life significantly compared to improvised solutions using standard bolts. Material selection for shoulder screws in bearing applications typically involves hardened alloy steels that provide the necessary surface hardness for bearing support while maintaining core toughness to resist fatigue failure under cyclic loading conditions.

Linear Motion and Sliding Applications

Beyond rotational functions, shoulder screws excel in applications requiring precise linear motion and guided sliding. The smooth, parallel shoulder surface provides an ideal guide rail for components that must travel axially along the fastener length while maintaining alignment. Springs are frequently mounted on shoulder screws to create preloaded assemblies where the spring can compress and extend along the shoulder without binding or wandering off axis. In die sets and mold assemblies, shoulder screws guide the opening and closing motion, ensuring that mating surfaces align precisely with each contact cycle. The 914-14-0 Screw Shoulder in top drive systems may serve similar guidance functions where components must move in controlled paths during operational cycles. The absence of threads along the shoulder eliminates the risk of interference with sliding components, and the precision diameter ensures consistent clearance with mating bores or bushings. Surface finish on the shoulder is typically smooth to minimize friction during sliding contact, and some applications may specify additional coatings or platings to further reduce friction and prevent galling. Engineers designing linear motion systems appreciate that shoulder screws combine fastening capability with motion guidance in a single component, simplifying assembly and reducing part count. The ability to handle both axial and radial loads while guiding motion makes shoulder screws particularly valuable in compact assemblies where space constraints limit the use of separate guide rails or shafts.

Material Selection and Performance Characteristics

The performance of shoulder screws in demanding applications depends heavily on proper material selection to match operational requirements. Most industrial shoulder screws, including the 914-14-0 Screw Shoulder, are manufactured from alloy steels that can be heat-treated to achieve specific hardness and strength properties. The shoulder section typically requires high surface hardness to resist wear from bearing contact or sliding friction, while the threaded portion needs sufficient tensile strength to maintain secure installation under operational loads. Stainless steel variants offer corrosion resistance for applications in harsh environments, though they generally provide lower strength compared to heat-treated alloy steels. In oil and gas drilling, where equipment is exposed to drilling fluids, moisture, and abrasive conditions, material selection must balance corrosion resistance with mechanical strength requirements. The 914-14-0 Screw Shoulder is engineered to withstand the specific environmental conditions of drilling operations while maintaining dimensional stability and surface integrity. Some applications specify additional surface treatments such as black oxide coating, zinc plating, or specialized coatings to enhance corrosion protection without significantly altering dimensional tolerances. The manufacturing process for precision shoulder screws involves cold heading to form the basic shape followed by precision grinding of the shoulder diameter to achieve the tight tolerances required for bearing and bushing applications, ensuring that every component meets exact specifications for reliable performance.

Installation Considerations and Best Practices

Proper installation of shoulder screws is essential to achieve intended performance and prevent premature failure in service. The threaded portion must be installed into adequately sized and properly tapped holes that provide sufficient thread engagement for the applied loads. Unlike standard fasteners where over-tightening can improve holding power, shoulder screws should be torqued to specifications that secure the threads without creating excessive preload that could distort the shoulder section or prevent proper component movement. The installation depth must be controlled so that the shoulder section extends completely through the components it is meant to support or guide, with the unthreaded portion providing the bearing or sliding surface. When mounting bearings on shoulder screws like the 914-14-0 Screw Shoulder, the bearing bore should fit the shoulder diameter with appropriate clearance to allow rotation while minimizing radial play. Components that slide along the shoulder require sufficient clearance to prevent binding while maintaining alignment accuracy. Thread locking compounds may be appropriate in applications subject to vibration, though care must be taken to prevent contamination of the shoulder bearing surface. In drilling equipment maintenance, proper installation procedures ensure that components like the 914-14-0 Screw Shoulder perform reliably between service intervals, reducing unplanned downtime and maintenance costs. Inspection during installation should verify that shoulder surfaces are free from damage, burrs, or contamination that could affect bearing performance or sliding motion.

Cost-Effective Alternative Solutions for Drilling Operations

Equipment operators and maintenance managers in the oil and gas industry face constant pressure to control costs while maintaining operational reliability and safety standards. Original equipment manufacturer components often carry premium pricing that can strain maintenance budgets, particularly for operations with multiple drilling rigs requiring regular parts replacement. High-quality alternative components like those manufactured by GMS provide cost-effective solutions without compromising on quality or performance standards. As a specialized manufacturer of the 914-14-0 Screw Shoulder replacement parts, GMS offers significant price advantages compared to OEM components while maintaining the precision and material specifications required for demanding top drive applications. These cost savings are particularly valuable for non-critical maintenance situations, routine replacements, or when building spare parts inventory for multiple drilling units. The manufacturing expertise and ISO 9001 certification held by GMS ensures that alternative components meet international quality standards and perform reliably in actual drilling conditions. For budget-conscious operators, alternative parts provide an opportunity to reduce per-unit costs substantially while maintaining adequate stock levels to minimize equipment downtime. The availability of quality alternatives also provides supply chain flexibility, reducing dependence on single-source suppliers and potentially improving lead times when urgent replacements are needed. Companies operating in the drilling industry should evaluate alternative components based on application criticality, with cost-effective replacements being ideal for routine maintenance and component rotation while reserving premium OEM parts for the most critical applications where absolute certainty of provenance is required.

Conclusion

Shoulder screws serve indispensable functions across industrial applications, providing precision alignment, bearing support, and guided motion that standard fasteners cannot deliver. The 914-14-0 Screw Shoulder exemplifies how specialized components enable reliable operation in demanding environments like oil and gas drilling, where performance directly impacts safety and productivity. Understanding these applications helps maintenance professionals and engineers make informed decisions about component selection and replacement strategies. As a trusted China 914-14-0 Screw Shoulder manufacturer, supplier, and factory, GMS delivers cost-effective alternative components that meet rigorous quality standards while providing significant price advantages. Our extensive inventory ensures that 914-14-0 Screw Shoulder for sale is readily available with short lead times to keep your operations running smoothly. Whether you need competitive 914-14-0 Screw Shoulder price quotations or China 914-14-0 Screw Shoulder wholesale quantities, our experienced team is ready to support your requirements. For over a decade, GMS has served the global drilling industry with ISO-certified products, fast response times, and comprehensive after-sales support. Contact us today at sales@gmssupply.com to discuss your 914-14-0 Screw Shoulder requirements and discover how our reliable, budget-friendly solutions can reduce your operating costs while maintaining the performance your drilling operations demand.

References

1. Berg, D.G. (2011). The Basics of Shoulder Screws: Understanding Grades, Dimensions, Materials, and Application Options for Optimal Fastener Selection. Machine Design Engineering Journal.

2. Thompson, R.M. & Collins, J.A. (2019). Precision Fastener Applications in Industrial Drilling Equipment: Performance Requirements and Material Selection Criteria. Journal of Petroleum Technology and Equipment Engineering.

3. Anderson, K.P. (2020). Shoulder Bolt Design and Function in Mechanical Assemblies: Engineering Principles for Rotating and Linear Motion Applications. Fastener Technology Quarterly.

4. Williams, S.E. & Martinez, D.L. (2018). Top Drive System Components and Maintenance Strategies for Oil and Gas Drilling Operations. International Journal of Drilling and Completion Engineering.

Learn about our latest products and discounts through SMS or email