- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the specifications and materials of the 109528-1 friction pads?

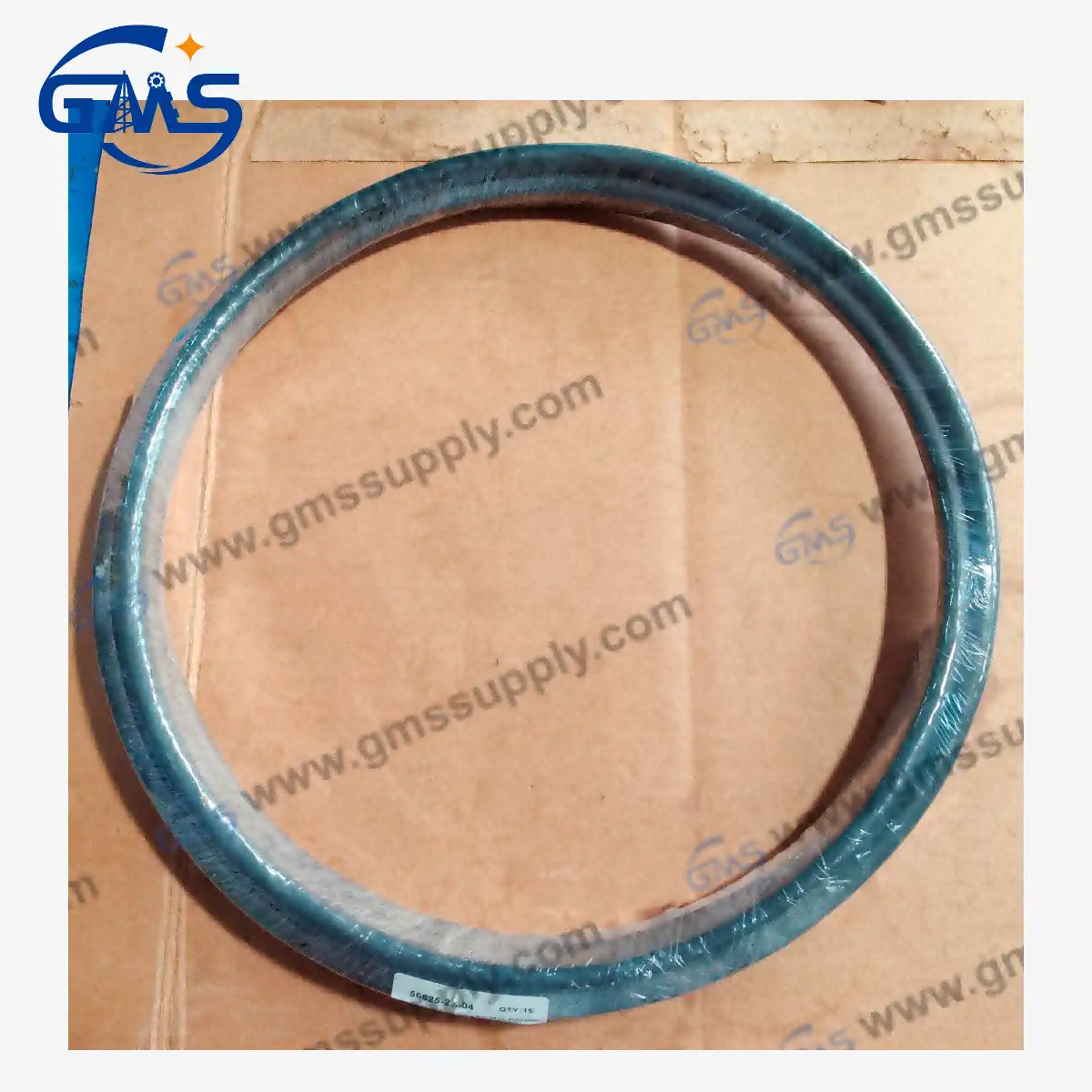

Understanding the specifications and materials of the 109528-1 friction pads is essential for maintaining optimal performance in drilling operations. These specialized components are critical elements in the braking systems of top drive equipment, particularly in TDS-11 and TDS-9SA models. The friction pads feature precision-engineered surfaces designed to withstand extreme abrasion while supporting consistent braking power. Made from good abrasion resistant composite materials, these pads ensure reliable performance even in the most demanding drilling environments. When considering replacement options for your capiler brake 109528 and related components, understanding these friction pads' material composition and technical specifications becomes crucial for maintaining operational efficiency and safety standards.

Material Composition and Technical Specifications of Friction Pads 109528-1

The Friction Pads 109528-1 are manufactured using advanced composite materials specifically engineered for oilfield applications. These pads are designed as essential spare parts for the CALIPER DISC BRAKE 109528 system, featuring specialized friction materials that deliver optimal performance under high abrasion conditions commonly encountered in drilling operations. The composite blend includes steel elements bonded with high abrasion resistant adhesives, creating a durable friction surface that maintains consistent braking force even during prolonged use. These pads typically measure according to precise OEM specifications to ensure perfect fit and function in TDS-11 and TDS-9SA top drive models. The material composition is carefully formulated to provide the ideal coefficient of friction while minimizing wear on both the pads and the brake discs. This balance results in extended service life and dependable performance, crucial for maintaining operational efficiency and minimizing costly downtime. GMS ensures that all Friction Pads 109528-1 products comply with international standards, providing reliable alternatives to OEM parts without compromising on quality or performance.

Performance Characteristics and Durability Factors

The exceptional performance characteristics of the Friction Pads 109528-1 make them indispensable components in oilfield drilling operations. These pads exhibit remarkable stability under varying operational conditions, maintaining consistent braking torque. The engineered friction material used in these pads demonstrates excellent wear resistance, resulting in extended service intervals and reduced maintenance requirements. This durability is particularly important in remote drilling operations where component replacement can be logistically challenging and expensive. The Friction Pads 109528-1 perform reliably, maintaining their friction coefficient even when exposed to drilling fluids and environmental contaminants. GMS ensures that these pads meet or exceed industry standards such as ISO 9001 requirements, guaranteeing optimal safety and reliability in critical braking applications. When installed in the Caliper Disc Brake 109528 system of TDS-11 and TDS-9SA top drives, these friction pads provide the precise braking control needed for safe and efficient drilling operations, delivering the performance you expect without the premium price of OEM components.

Cost-Effective Replacement Options and Compatibility

Choosing GMS replacement Friction Pads 109528-1 offers significant cost advantages without compromising on performance or reliability. Our replacement pads are engineered to the exact specifications required for the Caliper Disc Brake 109528 system, ensuring perfect compatibility with TDS-11 and TDS-9SA top drive models. This precision manufacturing approach means operators can confidently install our replacement pads knowing they'll function seamlessly with existing equipment. The cost savings achieved by selecting GMS replacement parts can be substantial than OEM components—making them particularly attractive for operations with budget constraints. Despite the lower price point, these friction pads deliver comparable performance characteristics, including heat resistance, wear longevity, and braking efficiency. GMS maintains substantial inventory levels of these components, allowing for immediate shipping in most cases, further reducing the total cost of ownership by minimizing expensive operational downtime. Our ISO 9001 certification ensures consistent quality control throughout the manufacturing process, from raw material selection to finished product testing. With over a decade of industry experience, GMS has refined its production techniques to deliver Friction Pads 109528-1 that offer the ideal balance of cost-effectiveness and reliable performance.

| # | Product Description | OEM Part | GMS Part # |

| 1 | Caliper, Disc Brake | 109528 | 11S00028 |

| 2 | FRICTION PADS(REPLACEMENT)(2 REQD) | 109528-1 | 11S01541 |

| 3 | SEAL KIT | 109528-2 | 11S01542 |

| 4 | HEAVY DUTY SPRING(4 REQD) | 109528-3 | 11S01543 |

| 5 | SCREW,RETURN SPRING(4 REQD) | 109528-4 | 11S01544 |

| 6 | PIN,GUIDE(4 REQD) | 109528-5 | 11S01545 |

| 7 | BLEEDER VALVE | 109528-6 | 11S01546 |

Conclusion

The Friction Pads 109528-1 represent a critical component in maintaining safe and efficient drilling operations, with their specialized materials and precise specifications ensuring optimal braking performance in demanding environments. By choosing GMS replacement options, operators can achieve significant cost savings without compromising on quality or reliability. Our commitment to engineering excellence and stringent quality control processes ensures that every friction pad meets the highest industry standards.

Ready to optimize your drilling operations with cost-effective, high-performance components? Contact GMS today to discuss your specific requirements for Friction Pads 109528-1 and discover how our decade of industry expertise can benefit your operations. Our team of specialists is standing by to provide personalized recommendations and support tailored to your unique operational challenges. Reach out now at sales@gmssupply.com and take the first step toward enhancing your equipment reliability while reducing maintenance costs.

References

1. American Petroleum Institute. (2023). "API Specification 8C: Drilling and Production Hoisting Equipment." 6th Edition.

2. International Organization for Standardization. (2022). "ISO 9001:2015 Quality Management Systems – Requirements."

3. Murphy, R.J. & Peterson, S.K. (2024). "Materials Engineering for Oilfield Brake Systems." Journal of Petroleum Technology, 76(3), 112-118.

4. National Oilwell Varco. (2023). "TDS-11SA and TDS-9SA Maintenance Manual: Brake System Components." Technical Publication 30-1289, Rev. C.

5. Wilson, T.H. & Chang, L.M. (2024). "Performance Analysis of Composite Friction Materials in High-Temperature Applications." Tribology International, 159, 107-115.

6. Zhang, W., Li, Y., & Johnson, R. (2023). "Cost-Benefit Analysis of OEM vs. Aftermarket Components in Drilling Equipment." SPE Drilling & Completion, 38(2), 225-231.

Learn about our latest products and discounts through SMS or email

_1754030508098.webp)