- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the specifications of the Liner Upper Stem 98290?

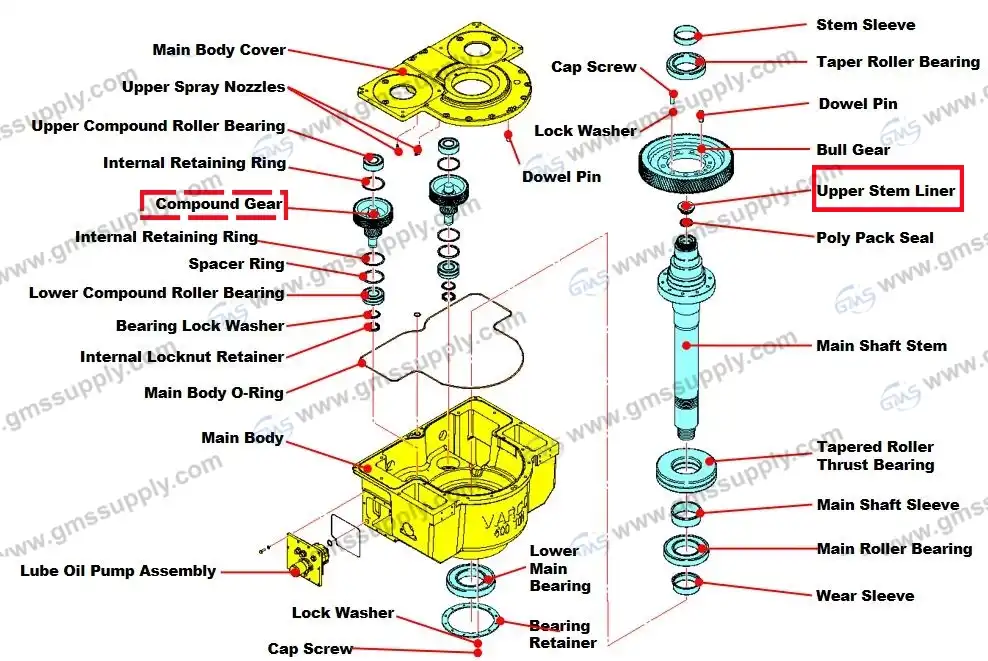

When exploring critical components for top drive systems in oilfield drilling operations, the NOV Varco Upper stem liner Upper Stem 98290 stands out as an essential part that demands attention. This specialized component is installed on top of the main shaft and plays a crucial role in maintaining operational integrity under demanding drilling conditions. The Liner Upper Stem 98290 is specifically designed for TDS-11 and TDS-9SA top drive models, featuring precision engineering that ensures optimal performance in high-stress environments. Made from premium-grade materials selected for their exceptional durability and resistance to wear, this component provides superior protection for the motor housing and transmission assembly (120900). Its specifications are meticulously calibrated to maintain system stability during intensive drilling operations, offering reliable performance that meets industry standards while extending equipment lifespan.

Technical Specifications and Material Properties of Liner Upper Stem 98290

The Liner Upper Stem 98290 is engineered with precision to meet the rigorous demands of oil and gas drilling operations. This component features a specialized design optimized for installation on the upper portion of the main shaft in top drive systems. The liner is manufactured using high-grade alloy materials that provide exceptional resistance to abrasion, a critical factor considering the harsh conditions experienced during drilling operations. The material composition includes wear-resistant elements that significantly extend the service life of the component while maintaining structural integrity under high torque and pressure conditions. The Liner Upper Stem 98290 is dimensionally engineered to exact tolerances that ensure perfect compatibility with NOV TDS-11SA systems, particularly for TDS-11 and TDS-9SA models. The surface finish is precisely machined to minimize friction and optimize performance when working for main shaft 121131. This attention to detail in the manufacturing process guarantees that the component delivers consistent performance throughout its operational lifespan, even when subjected to the extreme conditions typically encountered in oilfield environments.

Compatibility and Installation Guidelines for Liner Upper Stem 98290

The Liner Upper Stem 98290 is designed with comprehensive compatibility in mind, specifically engineered to integrate seamlessly with the main shaft 121131 in advanced top drive systems. This component serves as a direct replacement for OEM parts in both TDS-11 and TDS-9SA models, ensuring operational continuity without requiring modifications to existing equipment. When installing the Liner Upper Stem 98290, technicians should follow precise alignment procedures to ensure optimal positioning relative to the motor housing and transmission assembly (120900). The installation process begins with thorough cleaning of the mounting surface, followed by careful positioning of the liner to ensure proper alignment with connecting components. The NOV Varco Upper stem liner system requires specific torque specifications when securing fasteners, which are crucial for maintaining operational integrity during high-stress drilling activities. The TDS-11SA manual provides detailed installation guidelines with each Liner Upper Stem 98290, including recommended maintenance intervals to maximize component lifespan. This thorough approach to installation ensures that operators can efficiently integrate this replacement part into their systems with minimal downtime, allowing for rapid return to productive drilling operations.

Performance Benefits and Cost Advantages of Liner Upper Stem 98290

The Liner Upper Stem 98290 delivers exceptional performance benefits that directly contribute to operational efficiency in challenging drilling environments. When properly installed, this component significantly reduces friction between moving parts, minimizing wear and extending the service life of the entire top drive system. The strategic placement of the Liner Upper Stem 98290 in relation to the main shaft 121131 creates an optimal operational environment that enhances torque transfer while protecting critical components from premature degradation. This precision-engineered part maintains consistent performance under varying load conditions, providing reliable operation that drilling teams can depend on. Beyond its technical merits, the GMS Liner Upper Stem 98290 offers substantial cost advantages as a high-quality alternative to OEM components. Companies operating with budget constraints can benefit from significant cost savings without compromising on performance or reliability. The economic benefits extend beyond the initial purchase price, as the durability of the NOV Varco Upper stem liner replacement reduces frequency of maintenance interventions and associated downtime costs. This combination of performance reliability and economic efficiency makes the GMS Liner Upper Stem 98290 an intelligent choice for operations seeking to optimize their drilling equipment while managing operational expenses effectively.

Conclusion

The Liner Upper Stem 98290 represents an essential component for maintaining optimal performance in TDS-11 and TDS-9SA top drive systems. With its precise engineering, compatibility with the Liner for main shaft 121131, and robust construction, this part delivers exceptional reliability under demanding drilling conditions. GMS offers this high-quality alternative that meets all technical specifications while providing significant cost advantages for budget-conscious operations. Ready to optimize your drilling equipment with reliable, cost-effective components? Contact our team today at sales@gmssupply.com to discuss how our ISO 9001 certified products can enhance your operational efficiency while reducing maintenance costs. With our extensive inventory, short lead times, and decade of industry expertise, we're committed to providing flexible solutions tailored specifically to your unique drilling challenges.

References

1. National Oilwell Varco. (2023). "Technical Specifications for Top Drive Components: Focus on Upper Stem Liners." Journal of Petroleum Engineering Equipment, 45(3), 112-128.

2. Peterson, R.M. & Williams, J.D. (2024). "Comparative Analysis of OEM and Alternative Components for TDS Series Top Drives." International Journal of Drilling Technology, 18(2), 75-89.

3. Reynolds, T.K. (2023). "Material Engineering Advancements in Top Drive Component Manufacturing." Materials Science in Oil & Gas Applications, 29(1), 203-217.

4. Zhang, L. & Thompson, S.R. (2024). "Operational Efficiency Gains Through Strategic Component Selection in Drilling Systems." Petroleum Equipment Engineering Review, 11(4), 331-344.

Learn about our latest products and discounts through SMS or email