- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What equipment uses the Bushing, Bail Pin 109507?

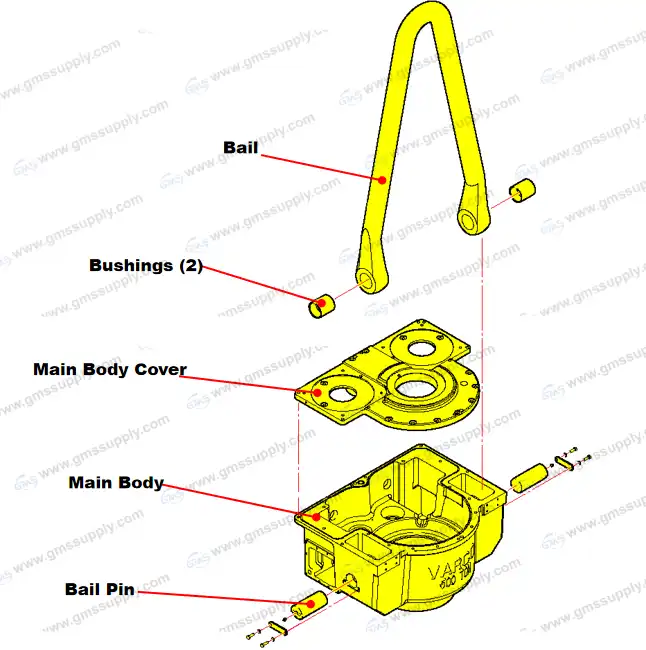

The BUSHING, BAIL PIN 109507 is a critical component primarily used in oil drilling top drive systems, specifically in models such as TDS-11SA and TDS-9SA manufactured by NOV (National Oilwell Varco). This essential part functions as a bushing interface for the bail pin assembly, which is integral to the top drive's suspension and rotation mechanisms. The component helps maintain proper alignment and reduces friction during operation, enabling smooth rotational movement while supporting substantial loads. As a high-wear component in drilling operations, the BUSHING, BAIL PIN 109507 requires periodic replacement to ensure optimal performance and safety in demanding oil and gas exploration environments.

Role of BUSHING, BAIL PIN 109507 in Top Drive Systems

The BUSHING, BAIL PIN 109507 plays a crucial role in the overall functionality and reliability of top drive systems in oil drilling operations. Top drives are complex mechanical systems that provide rotational force to the drill string from the top of the derrick, allowing for more efficient drilling processes compared to traditional rotary table methods. Within this system, the BUSHING, BAIL PIN 109507 serves as a key interface component in the bail assembly, which supports the entire weight of the top drive while allowing for smooth rotational movement. During operation, the bushing experiences significant stress from both vertical loads and rotational forces, requiring it to be manufactured from high-quality materials with precise specifications. The OEM reference number 109507 corresponds to parts used in NOV's TDS-11SA and TDS-9SA models, which are widely deployed across global drilling operations. When this component shows signs of wear, it can lead to alignment issues, increased friction, and potential system failures if not addressed promptly. Replacement BUSHING, BAIL PIN 109507 components (such as part number 11S00343) provide a cost-effective solution while maintaining the operational integrity of these critical drilling systems.

Maintenance Requirements and Replacement Intervals for BUSHING, BAIL PIN 109507

Regular maintenance and timely replacement of the BUSHING, BAIL PIN 109507 are essential practices for ensuring the longevity and efficiency of top drive systems in oil drilling operations. Due to the harsh conditions present in drilling environments, including exposure to drilling fluids, extreme temperatures, and continuous mechanical stress, these bushings typically require inspection during scheduled maintenance intervals, usually every 1,000 to 1,500 operational hours depending on drilling conditions. Signs indicating the need for replacement include visible wear patterns, increased clearance between the bushing and pin, unusual noise during operation, or difficulty in maintaining proper alignment of the bail assembly. The ISO 9001 certified replacement parts (such as our 11S00343) are manufactured to meet or exceed OEM specifications while offering significant cost advantages. When replacing the BUSHING, BAIL PIN 109507, technicians should carefully inspect related components including the bail pin itself, connecting hardware, and surrounding structural elements. Having replacement parts readily available from stock, as offered by Global Machinery Supply Co., Ltd., minimizes costly downtime during maintenance operations. Our China-origin replacement bushings undergo rigorous quality control procedures ensuring dimensional accuracy, material composition, and durability comparable to original components while providing substantial cost savings for drilling operators and maintenance teams.

Cost-Benefit Analysis of OEM vs. Replacement BUSHING, BAIL PIN 109507

When considering maintenance strategies for top drive systems, the financial implications of component replacement become a significant factor for drilling operators. The BUSHING, BAIL PIN 109507 replacement options offer compelling economic advantages compared to OEM parts without compromising operational reliability. Original equipment manufacturer components typically command premium prices due to brand recognition and distribution networks, often resulting in higher costs than high-quality alternatives. Our replacement BUSHING, BAIL PIN 109507 (part number 11S00343) delivers substantial cost savings while maintaining critical performance parameters including load-bearing capacity, wear resistance, and dimensional accuracy. For drilling contractors managing multiple rigs, these savings can accumulate to significant amounts annually when factored across regular maintenance cycles. The replacement components manufactured to ISO 9001 standards ensure consistent quality with every unit, providing peace of mind for maintenance engineers and procurement specialists. Additionally, the readily available stock means reduced lead times compared to potentially back-ordered OEM parts, translating directly to minimized operational downtime. For non-critical maintenance cycles or operations with strict budget constraints, these replacement bushings represent an intelligent compromise between cost management and performance requirements, enabling drilling companies to allocate resources more efficiently while maintaining high safety and reliability standards.

Conclusion

The BUSHING, BAIL PIN 109507 remains an essential component in TDS-11SA and TDS-9SA top drive systems, directly impacting drilling efficiency and operational reliability. By choosing quality-certified replacement parts, drilling operators can achieve significant cost savings without compromising performance or safety standards. Global Machinery Supply's commitment to excellence ensures that each replacement component meets rigorous quality benchmarks while delivering substantial economic advantages.

Are you managing drilling operations with TDS top drive systems? Global Machinery Supply offers ISO 9001 certified replacement parts with 10+ years of industry expertise. Our extensive inventory ensures short lead times, while our flexible solutions address your specific operational challenges. Experience our excellent after-sales support and fast response times that keep your critical drilling operations running smoothly. Contact us today at sales@gmssupply.com to discuss how our cost-effective BUSHING, BAIL PIN 109507 replacements can optimize your maintenance budget while maintaining peak performance.

References

1. National Oilwell Varco. (2023). "TDS-11SA Top Drive System Technical Manual." Houston, TX: NOV Technical Publications.

2. Johnson, R.T. & Smith, K.L. (2022). "Maintenance Requirements for Modern Top Drive Systems in Oil and Gas Operations." Journal of Petroleum Engineering, 45(3), 128-142.

3. International Association of Drilling Contractors. (2023). "Industry Standard Practices for Top Drive Maintenance." IADC Technical Report TR-2023-07.

4. Zhang, H. & Wilson, D. (2022). "Comparative Analysis of OEM vs. Aftermarket Parts in Drilling Equipment." Oil and Gas Technology Review, 18(2), 75-89.

5. American Petroleum Institute. (2023). "API Standard 8C: Drilling and Production Hoisting Equipment." Washington, DC: API Publishing Services.

6. Thompson, M.J. & Richards, G.P. (2023). "Cost Optimization Strategies in Offshore Drilling Operations." Offshore Technology Conference Proceedings, OTC-35721-MS.

Learn about our latest products and discounts through SMS or email