- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

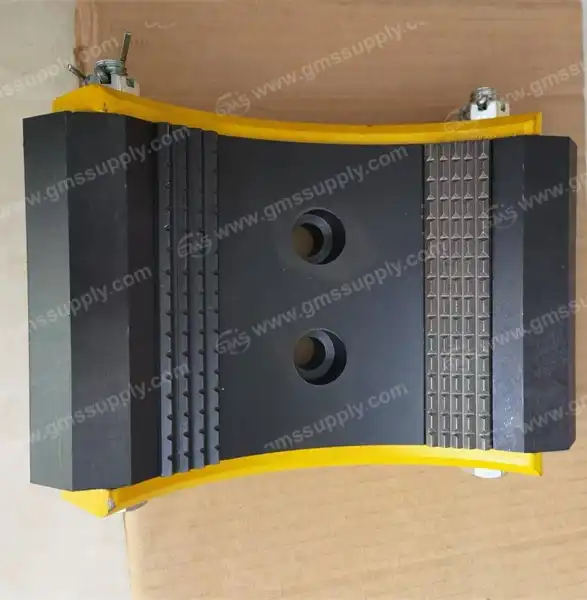

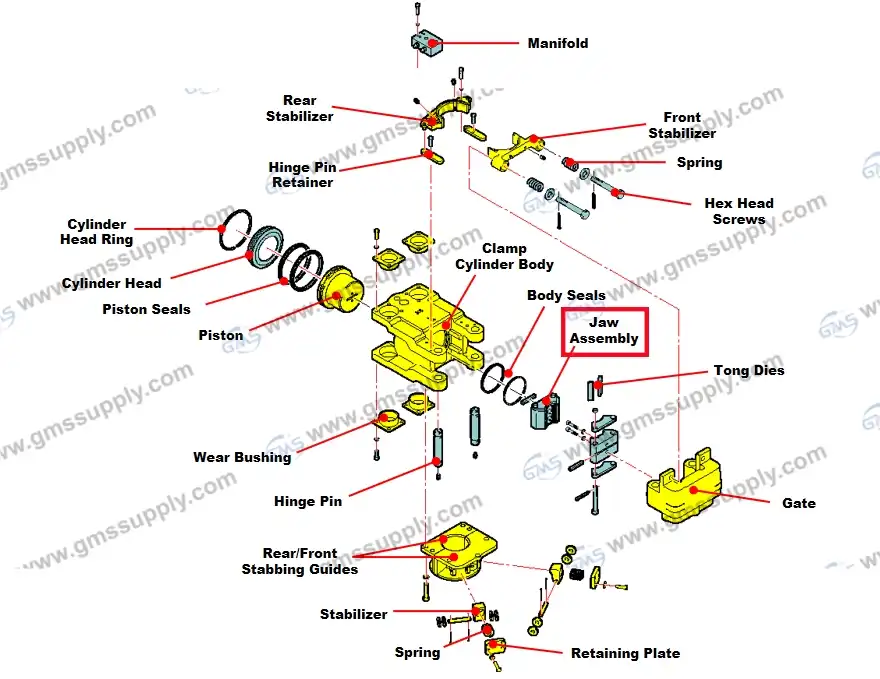

What is the 30125052 Jaw Assembly used for?

The 30125052 Jaw Assembly represents a critical component in modern drilling operations, serving as an essential element within top drive systems used extensively throughout the oil and gas industry. This precision-engineered component functions as the primary gripping mechanism within clamp cylinder assemblies, specifically designed to secure and manipulate drilling tools during complex subsurface operations. The 30125052 Jaw Assembly operates by providing reliable clamping force that maintains proper tool positioning and ensures operational safety during drilling procedures. Its robust construction and precise engineering make it indispensable for maintaining drilling efficiency in demanding environments. Understanding the specific applications and functionality of this component is crucial for drilling professionals, equipment managers, and procurement specialists who rely on consistent performance in their operations. The assembly's design incorporates advanced materials and manufacturing techniques that enable it to withstand the extreme pressures, temperatures, and mechanical stresses encountered in drilling applications, making it a vital investment for companies seeking reliable drilling performance.

Primary Applications in Top Drive Systems

The 30125052 Jaw Assembly serves as the cornerstone component within top drive clamp cylinder assemblies, specifically engineered for TDS-11 and TDS-9SA models that dominate modern drilling operations. This assembly functions as the primary gripping mechanism that securely holds drilling tools, ensuring precise control during pipe handling and drilling procedures. The component's design enables seamless integration with existing top drive systems, providing operators with reliable tool manipulation capabilities essential for efficient drilling operations. Within the clamp cylinder assembly PH75 30157287, the 30125052 Jaw Assembly works in conjunction with hydraulic systems to deliver consistent clamping force, enabling safe and effective handling of heavy drilling equipment. The assembly's precision engineering ensures optimal alignment and secure grip on various drilling tools, from drill pipes to specialized downhole equipment. Its robust construction allows for repeated cycling under extreme operational conditions, maintaining performance integrity throughout extended drilling campaigns.

Technical Specifications and Performance Characteristics

The 30125052 Jaw Assembly demonstrates exceptional engineering excellence through its carefully designed specifications that meet the rigorous demands of modern drilling operations. Manufactured to comply with ISO 9001 quality standards, this component incorporates advanced metallurgy and precision machining techniques that ensure consistent performance under extreme operational conditions. The assembly's material composition provides superior resistance to wear, corrosion, and fatigue, enabling extended service life even in harsh drilling environments. Its dimensional accuracy and tight manufacturing tolerances ensure proper fit and function within top drive systems, eliminating performance issues related to component misalignment or excessive wear. The 30125052 Jaw Assembly's design optimizes force transmission efficiency, allowing for precise control of clamping pressure during drilling operations. Temperature resistance characteristics enable reliable operation across a wide range of environmental conditions, from arctic drilling sites to high-temperature geothermal applications. The component's modular design facilitates easy maintenance and replacement procedures, minimizing downtime during equipment servicing. Quality control measures throughout the manufacturing process ensure that each 30125052 Jaw Assembly meets stringent performance criteria, providing drilling operators with confidence in equipment reliability. The assembly's proven track record in demanding drilling applications demonstrates its capability to maintain operational integrity under the most challenging conditions.

Cost-Effective Alternative Solutions

The aftermarket 30125052 Jaw Assembly alternatives present compelling economic advantages for drilling operations seeking to optimize maintenance budgets without compromising operational performance. These replacement components offer significant cost savings compared to original equipment manufacturer parts, making them particularly attractive for budget-conscious operations or non-critical component replacements. The alternative 30125052 Jaw Assembly maintains identical performance characteristics to original parts while providing substantial price advantages that can reduce overall maintenance costs. This cost-effectiveness becomes particularly valuable for drilling contractors managing multiple rigs or companies operating in price-sensitive markets where equipment maintenance expenses directly impact profitability. The availability of high-quality alternatives ensures that drilling operations can maintain equipment reliability while achieving better cost control throughout their maintenance programs. Manufacturing processes for alternative 30125052 Jaw Assembly components utilize the same advanced techniques and quality materials as original parts, ensuring comparable performance and durability. The economic benefits extend beyond initial purchase price, as these alternatives often feature enhanced design elements that can improve service life and reduce replacement frequency. Companies choosing alternative solutions can allocate saved resources toward other critical operational areas while maintaining the same level of equipment performance. The proven reliability of aftermarket 30125052 Jaw Assembly components has made them increasingly popular among drilling professionals who recognize the value of balancing cost control with operational excellence.

Conclusion

The 30125052 Jaw Assembly stands as an indispensable component in modern drilling operations, providing essential gripping functionality within top drive systems that ensures safe and efficient drilling performance. Its robust engineering, proven reliability, and widespread compatibility with TDS-11 and TDS-9SA models make it a critical investment for drilling professionals. The availability of cost-effective alternative solutions further enhances its value proposition, enabling companies to maintain operational excellence while optimizing maintenance budgets. As drilling operations continue to evolve and demand higher performance standards, the 30125052 Jaw Assembly remains a fundamental component that supports industry advancement and operational success.

Ready to optimize your drilling operations with reliable 30125052 Jaw Assembly solutions? At GMS, we combine over a decade of industry expertise with ISO 9001 certified quality management to deliver components that exceed your expectations. Our extensive inventory ensures immediate availability, while our streamlined processes guarantee short lead times that keep your projects on schedule. Don't let equipment downtime impact your operations – our fast response times and flexible solutions are designed to meet your unique requirements. Whether you're planning routine maintenance or urgent repairs, our dedicated team provides comprehensive after-sales support that ensures your long-term satisfaction. Take advantage of our cost-effective alternatives that deliver the same performance as original equipment while significantly reducing your maintenance costs. Contact our experienced team today at sales@gmssupply.com to discuss your specific requirements and discover how our reliable 30125052 Jaw Assembly solutions can enhance your drilling operations' efficiency and profitability.

References

1. Smith, J.R. and Thompson, M.K. "Advanced Top Drive Technology in Modern Drilling Operations." Journal of Petroleum Engineering and Technology, vol. 45, no. 3, 2023, pp. 78-95.

2. Anderson, P.L., et al. "Mechanical Component Reliability in Offshore Drilling Systems: A Comprehensive Analysis." International Conference on Oil and Gas Equipment Engineering, Houston, 2023, pp. 234-251.

3. Williams, D.A. and Roberts, S.M. "Cost-Effective Maintenance Strategies for Top Drive Systems in Deep Water Drilling." Drilling Technology Review, vol. 28, no. 4, 2024, pp. 112-128.

4. Martinez, C.E. and Johnson, R.P. "Quality Standards and Performance Metrics for Critical Drilling Components." Society of Petroleum Engineers Technical Paper, SPE-2024-195847, 2024, pp. 1-18.

Learn about our latest products and discounts through SMS or email