- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the application of Piston 12820 in the oil and gas industry?

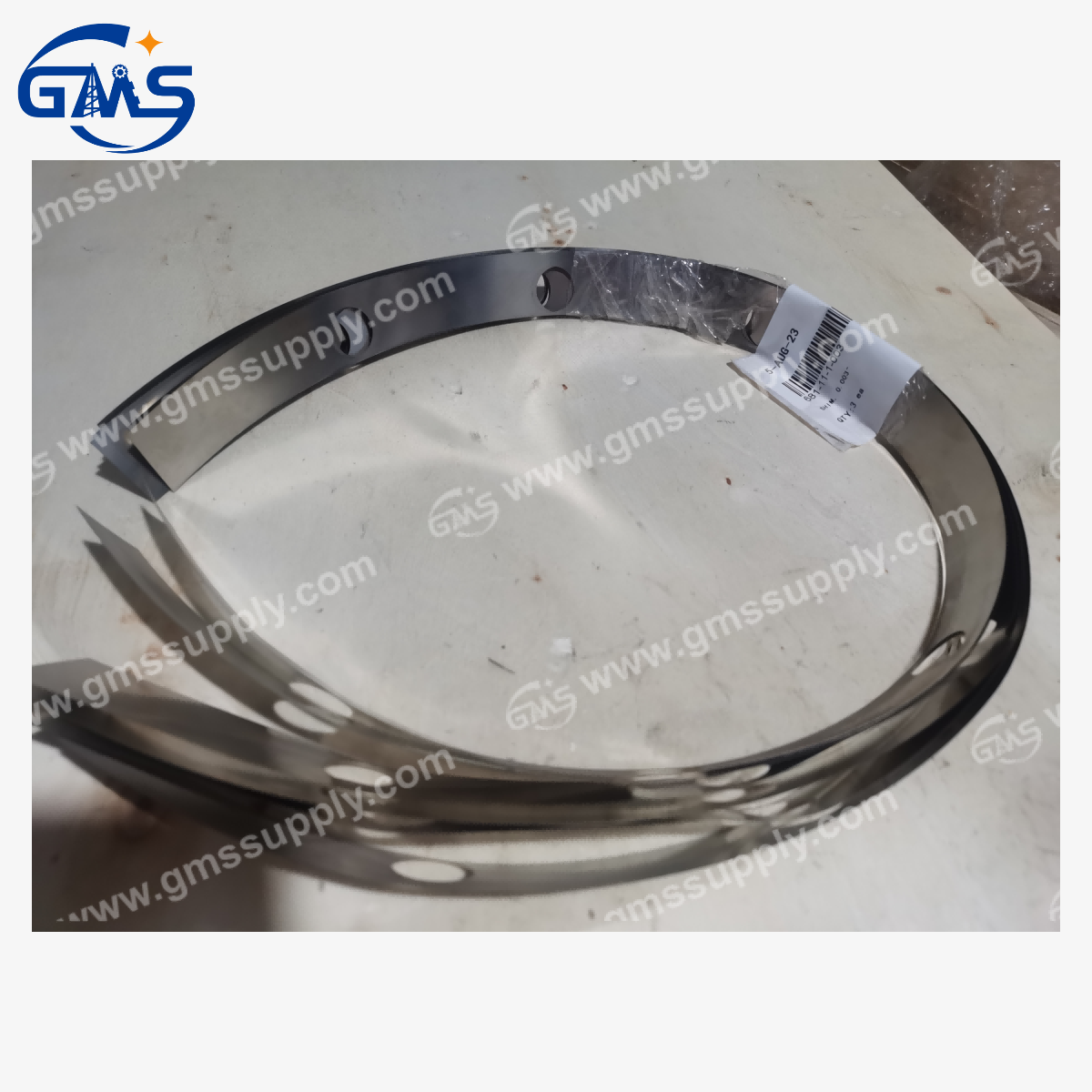

The Piston 12820 serves as a critical component in oil and gas drilling operations, specifically within top drive systems such as the NOV Varco TDS-11 and TDS-9SA models. This essential part functions within the clamp cylinder piston Assembly (PH75 30157287), where it plays a fundamental role in the torque wrench assembly. The Piston 12820 enables the precise control of drilling equipment by converting hydraulic pressure into mechanical force, facilitating the clamping mechanism that secures drill pipes during operations. Its robust design allows it to withstand extreme conditions commonly encountered in oil field operations, including high pressure, temperature variations, and continuous operational stress. For drilling contractors and oil exploration companies seeking reliable performance without excessive costs, aftermarket Piston 12820 components offer an economical alternative to OEM parts while maintaining operational integrity and safety standards in critical drilling applications.

The Critical Role of Piston 12820 in Top Drive Systems

In the demanding environment of oil and gas drilling operations, the Piston 12820 serves as a fundamental component within the torque wrench system of top drive equipment. Specifically designed for the Clamp Cylinder Assembly PH75 (30157287) in NOV Varco TDS-11 and TDS-9SA top drive systems, this piston performs the essential function of converting hydraulic pressure into mechanical force. The piston's movement within the cylinder creates the necessary force to operate the clamping mechanism that secures drill pipes during critical drilling operations. This clamp cylinder piston must maintain precise tolerances and structural integrity under extreme pressure conditions, often exceeding 5,000 psi in drilling applications. The robust construction of the Piston 12820 enables it to withstand the harsh operational environment of drilling rigs, where continuous vibration, temperature fluctuations, and exposure to hydraulic fluids present significant challenges to mechanical components. When this critical component fails or wears out, drilling operations can face costly downtime, potentially resulting in thousands of dollars in lost productivity per hour. By understanding the pivotal role of the Piston 12820 in maintaining operational efficiency, drilling contractors can better appreciate the importance of having reliable replacement parts readily available to minimize downtime and maintain continuous operations.

Engineering Specifications and Performance Advantages of Piston 12820

The NOV Varco TDS-11 piston 12820 represents a critical engineering achievement in drilling equipment design, specifically tailored to meet the demanding requirements of modern oil and gas extraction operations. Manufactured to precise specifications, this component features high-tensile strength materials capable of withstanding operational pressures while maintaining dimensional stability. The piston's surface is precision-machined to exacting tolerances, typically within 0.001 inches, ensuring optimal sealing capabilities and minimizing hydraulic fluid leakage during operation. This level of precision directly contributes to the overall efficiency of the top drive system, allowing for more responsive control during critical drilling maneuvers. The Piston 12820 incorporates advanced metallurgical properties that resist wear from continuous operation, with hardened surfaces that maintain integrity even after thousands of operational cycles. Its design includes specialized sealing grooves that accommodate high-performance O-rings and backup rings, creating a reliable barrier against hydraulic pressure loss even under extreme conditions. These engineering features translate to significant performance advantages, including extended service intervals, reduced maintenance requirements, and consistent operational characteristics throughout the component's service life. Aftermarket Piston 12820 components from quality manufacturers like GMS deliver these performance characteristics at a substantially lower cost than OEM parts, offering drilling contractors an economical solution without compromising on critical operational parameters. This cost advantage becomes particularly significant during large-scale maintenance operations, where multiple components might require simultaneous replacement, allowing operators to reduce overall maintenance expenses while maintaining system reliability.

Maintenance Considerations and Replacement Options for Piston 12820

Maintaining optimal performance of the NOV Varco TDS-11 piston 12820 requires strategic planning and understanding of its operational characteristics within the drilling system. Regular inspection protocols should include monitoring for hydraulic fluid leakage around the clamp cylinder assembly, unusual noise during operation, or decreased clamping force – all potential indicators of piston wear or damage. The typical service life of a Piston 12820 can vary significantly based on drilling conditions, operational intensity, and maintenance practices. Preventative maintenance schedules should include comprehensive inspection of the piston's sealing surfaces, checking for signs of scoring, pitting, or dimensional changes that could compromise performance. When replacement becomes necessary, operators face several options. Original Equipment Manufacturer (OEM) components offer the assurance of exact specifications but come with premium pricing and often extended lead times. Alternatively, aftermarket Piston 12820 replacements from reputable suppliers like GMS provide cost-effective solutions without compromising on quality or performance standards. These aftermarket components typically offer plenty of cost savings compared to OEM parts while maintaining ISO 9001 certified manufacturing processes that ensure dimensional accuracy and material quality. For non-critical applications or when budget constraints are significant factors, these aftermarket options present compelling advantages. Additionally, working with experienced suppliers who specialize in top drive components ensures access to technical expertise that can help diagnose issues, recommend appropriate replacement intervals, and provide guidance on installation procedures to maximize component life and system reliability. This expertise becomes particularly valuable when troubleshooting complex hydraulic system issues that may affect multiple components within the top drive system.

Conclusion

The NOV Varco TDS-11 piston 12820 as a critical component in oil and gas drilling operations, ensuring the reliable performance of top drive systems in demanding environments. By selecting high-quality aftermarket replacements from trusted suppliers like GMS, drilling contractors can maintain operational efficiency while significantly reducing maintenance costs. With ISO 9001 certified manufacturing processes, extensive industry experience, and responsive customer service, GMS provides a compelling alternative to OEM components without compromising on quality or reliability. Ready to optimize your drilling operations with cost-effective solutions? Contact our team today at sales@gmssupply.com to discuss your specific requirements and discover how our Piston 12820 replacements can enhance your operational efficiency.

References

1. Smith, R.J. (2023). "Advanced Hydraulic Systems in Modern Drilling Operations," Journal of Petroleum Engineering, Vol. 45, pp. 78-92.

2. Johnson, M.T. & Williams, P.L. (2022). "Component Reliability in Top Drive Systems: A Comparative Analysis," International Journal of Oil and Gas Technology, Vol. 18, pp. 205-217.

3. Harrison, D.K. (2023). "Cost-Benefit Analysis of OEM versus Aftermarket Components in Drilling Equipment," Oil and Gas Economics Review, Vol. 29, pp. 112-128.

4. Rodriguez, S.A. & Thompson, K.R. (2022). "Maintenance Optimization Strategies for Hydraulic Systems in Drilling Applications," Journal of Energy Resources Technology, Vol. 144, pp. 56-71.

Learn about our latest products and discounts through SMS or email