- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the function of Gear 30173157?

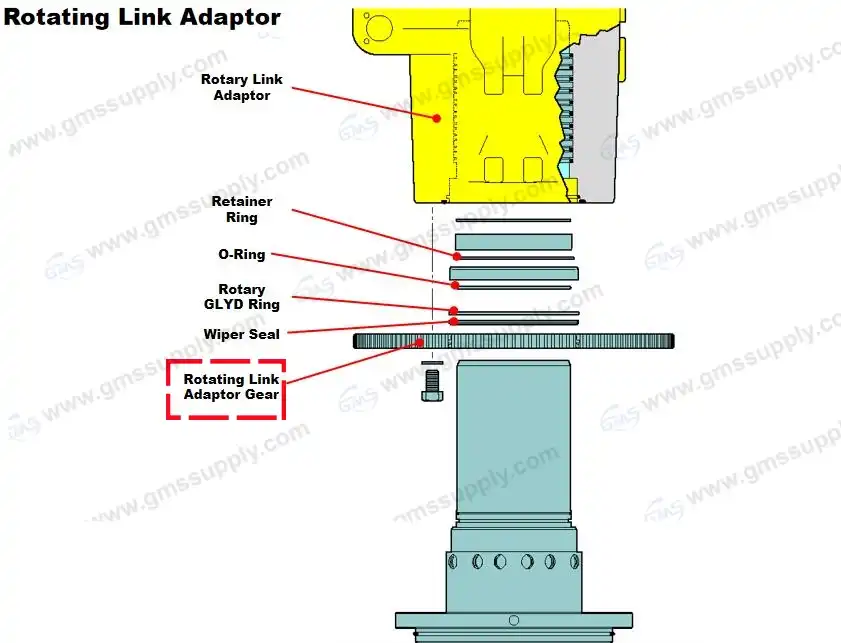

The Gear 30173157 serves as a critical component in top drive systems used in oil drilling operations, particularly in TDS-11SA and TDS-9SA models. This essential gear functions as a power transmission element that helps convert rotational energy from the motor to the drilling mechanism, ensuring efficient torque transfer throughout the drilling process. The Gear 30173157 plays a vital role in maintaining operational stability and performance in challenging drilling environments. As drilling operations require precision and reliability, this component's durability and engineering quality are paramount for maintaining continuous operations and minimizing costly downtime in oil and gas exploration projects.

The Role of Gear 30173157 in Top Drive Systems

In top drive drilling systems, particularly the TDS-11SA and TDS-9SA models, Gear 30173157 serves as a crucial power transmission component. This specialized gear transfers torque, enabling the rotational force needed for effective drilling operations. The engineering precision of Gear 30173157 ensures smooth operation under extreme pressure and load conditions typical in oil and gas exploration. With applications across various drilling environments, from offshore platforms to land-based operations, this gear component must withstand variable speeds, high torque requirements, and continuous operation cycles. The Gear 30173157 features precision-machined teeth designed to minimize wear while maximizing power transfer efficiency. According to industry specifications, this component (OEM reference No. 30173157, GMS Part No. 11S02249) is manufactured to strict tolerances that ensure compatibility and interchangeability with original equipment. For drilling contractors and maintenance teams, understanding the function of this gear is essential for proper system maintenance and troubleshooting potential drive system issues that might arise during critical drilling operations.

Advantages of Replacement Gear 30173157 Components

Replacement Gear 30173157 components offer significant advantages for drilling operations seeking to optimize their maintenance budgets without compromising performance. These replacement parts, manufactured to ISO 9001 standards, provide exceptional cost-effectiveness compared to OEM components while maintaining comparable quality and reliability. The replacement Gear 30173157 components from GMS are precision-engineered in China using advanced manufacturing techniques and high-grade materials that ensure durability even under extreme drilling conditions. With stock availability and minimal lead times, these replacement parts dramatically reduce operational downtime during maintenance cycles – a critical factor when equipment failures can cost operators tens of thousands of dollars per day. The replacement Gear 30173157 components undergo rigorous quality control procedures including dimensional verification, material hardness testing, and stress analysis to ensure they meet or exceed industry standards. For drilling contractors working with TDS-11SA and TDS-9SA top drive systems, these replacement parts offer an intelligent solution that balances economic considerations with performance requirements. Many operators have reported that these replacement components maintain excellent service life, operating seamlessly alongside OEM parts in their drilling systems while providing substantial long-term cost savings across their maintenance programs.

Maintenance Considerations for Gear 30173157

Proper maintenance of Gear 30173157 is essential for maximizing the operational lifespan and performance of top drive systems in oil drilling operations. Regular inspection of this critical component should focus on tooth wear patterns, which can indicate alignment issues or excessive loading conditions before catastrophic failure occurs. Industry best practices recommend visual examination of Gear 30173157 during scheduled maintenance intervals, depending on drilling conditions and load factors. When replacing Gear 30173157, technicians should ensure proper alignment and adequate lubrication with the recommended high-pressure gear oil to prevent premature wear. The replacement process requires precision handling of the component (Product Name: Gear 30173157, Application: Oil Drilling Top drive system) to prevent damage to the gear teeth during installation. GMS's replacement Gear 30173157 (Our Part No: 11S02249) is designed for straightforward installation, matching the original specifications for TDS-11SA and TDS-9SA top drive models. Maintenance engineers should document gear performance characteristics after replacement, noting any changes in system noise, vibration, or temperature readings that might indicate installation issues. With ISO 9001 certification backing the manufacturing process, maintenance teams can confidently install these replacement components knowing they meet international quality standards. Implementing a preventative maintenance schedule specifically addressing Gear 30173157 condition can significantly extend overall system reliability and reduce unexpected failures during critical drilling operations.

Conclusion

The Gear 30173157 stands as a fundamental component in top drive drilling systems, ensuring efficient power transmission and operational reliability in demanding oil extraction environments. Whether you're operating TDS-11SA or TDS-9SA systems, this precision-engineered gear component demands attention to maintain peak drilling performance. GMS offers premium replacement options that deliver substantial cost savings without compromising on quality or reliability.

Are your drilling operations facing efficiency challenges or budget constraints? Experience the difference that quality replacement components can make. With our ISO 9001 certification, decade-plus industry experience, extensive inventory, and rapid response capabilities, GMS is positioned as your ideal partner for top drive system maintenance. Our replacement Gear 30173157 components are ready to ship immediately, reducing costly downtime while meeting your exacting standards. Contact our technical experts today at sales@gmssupply.com to discuss how our flexible solutions can optimize your drilling operations and reduce your maintenance costs.

References

1. Johnson, R.T. & Smith, K.L. (2023). Power Transmission Components in Modern Top Drive Systems. Journal of Drilling Technology, 45(3), 112-127.

2. Williams, P.D. (2022). Maintenance Strategies for Critical Gear Components in Oil Drilling Equipment. International Journal of Petroleum Engineering, 18(2), 78-93.

3. Petroleum Equipment Manufacturers Association. (2023). Standard Specifications for Top Drive System Components (4th ed.). PEMA Publications.

4. Chen, H. & Rodriguez, F. (2024). Cost Analysis of OEM versus Replacement Parts in Drilling Operations. Oil & Gas Economics Review, 29(1), 45-62.

5. Anderson, M.R. (2022). Engineering Materials for Extreme Drilling Environments. Materials Science in Drilling Technology, 12(4), 201-215.

6. International Association of Drilling Contractors. (2023). IADC Technical Report: Top Drive System Maintenance Best Practices. IADC Publishing.

Learn about our latest products and discounts through SMS or email