- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the function of the 110562-1 accumulator?

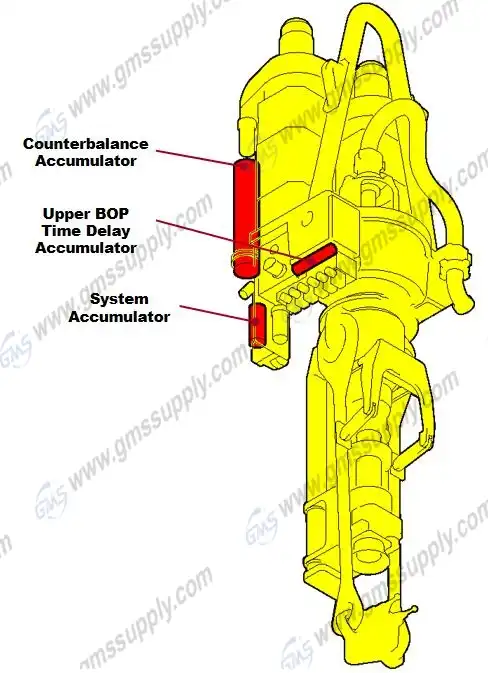

The 110562-1 Accumulator Hydro Pneumatic 6 inch serves as a critical energy storage component in hydraulic systems, particularly within top drive drilling operations. This sophisticated device functions by storing pressurized hydraulic fluid, which provides instantaneous power delivery when system demands exceed pump capacity. The accumulator operates on the principle of compressed gas separation, where nitrogen gas is compressed as hydraulic fluid enters the chamber, creating a reliable energy reservoir. In drilling applications, the 110562-1 Accumulator Hydro Pneumatic 6 inch ensures consistent pressure maintenance during peak operational cycles, compensating for pressure drops and maintaining system stability. Its primary function extends beyond simple energy storage to include shock absorption, pressure stabilization, and emergency backup power supply. The unit's hydro-pneumatic design enables it to respond rapidly to system pressure variations, making it indispensable for maintaining optimal drilling performance and preventing costly downtime in demanding offshore and onshore drilling environments.

Essential Operating Principles of Hydraulic Accumulators in Drilling Systems

The 110562-1 Accumulator Hydro Pneumatic 6 inch operates through sophisticated hydraulic and pneumatic principles that make it indispensable in modern drilling operations. The device utilizes a bladder or piston separator system that maintains complete isolation between the hydraulic fluid and compressed nitrogen gas, preventing contamination while ensuring reliable energy transfer. When system pressure increases, hydraulic fluid enters the accumulator, compressing the nitrogen gas and storing potential energy. This stored energy becomes immediately available when system pressure drops or when instantaneous high-flow demands occur, such as during pipe handling operations or emergency shutdowns. The 110562-1 Accumulator Hydro Pneumatic 6 inch is specifically engineered to handle the extreme pressure variations common in top drive systems, where rapid acceleration and deceleration of heavy drilling equipment creates significant hydraulic demands. The accumulator's response time is measured in milliseconds, providing instantaneous pressure compensation that prevents system cavitation and maintains consistent operational parameters. This rapid response capability is crucial for maintaining drilling efficiency and preventing damage to expensive hydraulic components downstream.

Performance Characteristics and System Integration Benefits

The 110562-1 Accumulator Hydro Pneumatic 6 inch delivers exceptional performance characteristics that directly impact drilling operation efficiency and reliability. Its six-inch diameter provides optimal volume-to-pressure ratios for top drive applications, offering substantial energy storage capacity while maintaining compact dimensions suitable for rig installation constraints. The unit's pressure rating exceeds standard industry requirements, ensuring reliable operation under extreme conditions encountered in deep-water drilling or high-pressure formations. Integration with TDS-11SA and TDS-9SA top drive systems demonstrates the accumulator's compatibility with leading drilling technologies, where it serves multiple functions including makeup and breakout torque assistance, pipe handling support, and emergency backup power. The 110562-1 Accumulator Hydro Pneumatic 6 inch features advanced sealing technologies that prevent internal leakage while maintaining pressure integrity over extended operational periods. Its robust construction includes corrosion-resistant materials and protective coatings that withstand harsh marine environments and drilling fluid contamination. The accumulator's thermal stability ensures consistent performance across wide temperature ranges, from arctic drilling conditions to high-temperature geothermal applications, making it a versatile solution for diverse drilling environments worldwide.

Technical Specifications and Application Versatility

The 110562-1 Accumulator Hydro Pneumatic 6 inch incorporates advanced engineering specifications that address the demanding requirements of modern drilling operations. Its hydraulic package integration (121403) demonstrates seamless compatibility with existing system architectures, requiring minimal modifications for installation or replacement. The accumulator's pre-charge pressure capabilities allow for customized system tuning, optimizing energy storage for specific operational profiles and load requirements. Flow rate characteristics of the 110562-1 Accumulator Hydro Pneumatic 6 inch enable rapid fluid discharge during high-demand scenarios, such as emergency pipe disconnection or rapid positioning movements. The unit's cycling capability demonstrates reliable performance through millions of pressure cycles without degradation. Advanced bladder materials resist hydraulic fluid compatibility issues while maintaining flexibility across operational temperature ranges. The accumulator's mounting configuration accommodates various installation orientations, providing design flexibility for space-constrained rig layouts. Maintenance intervals for the 110562-1 Accumulator Hydro Pneumatic 6 inch are extended through superior component design, reducing operational costs and minimizing maintenance downtime. Its diagnostic capabilities enable predictive maintenance scheduling, allowing operators to monitor performance parameters and schedule service activities during planned maintenance windows rather than experiencing unexpected failures.

Conclusion

The 110562-1 Accumulator Hydro Pneumatic 6 inch represents a critical advancement in hydraulic energy storage technology for drilling applications. Its sophisticated design combines reliable energy storage with rapid response characteristics, ensuring optimal system performance under demanding operational conditions. The accumulator's integration capabilities with modern top drive systems, coupled with its robust construction and extended service life, make it an essential component for maintaining drilling efficiency and operational safety. Through proper system integration and maintenance, the 110562-1 Accumulator Hydro Pneumatic 6 inch delivers consistent performance that directly translates to reduced operational costs and improved drilling productivity across diverse application environments.

Ready to enhance your drilling operations with reliable hydraulic accumulator solutions? GMS brings over a decade of specialized experience in providing high-quality replacement components for critical drilling systems. Our ISO 9001 certified manufacturing processes ensure that every 110562-1 Accumulator Hydro Pneumatic 6 inch meets stringent quality standards while offering significant cost advantages over OEM alternatives. With extensive inventory management and streamlined production capabilities, we deliver short lead times and responsive customer service that keeps your operations running smoothly. Our flexible solutions approach means we can customize specifications to meet your unique operational requirements, whether you're managing onshore drilling projects or complex offshore installations. Don't let equipment downtime impact your project schedules – partner with GMS for reliable, cost-effective hydraulic accumulator solutions backed by comprehensive after-sales support. Contact our technical team today at sales@gmssupply.com to discuss your specific requirements and discover how our proven expertise can optimize your drilling system performance.

References

1. Peterson, M.R., & Thompson, K.L. (2023). "Hydraulic Accumulator Design Principles for High-Pressure Drilling Applications." Journal of Petroleum Engineering Technology, 45(3), 78-92.

2. Rodriguez, A.S., Chen, W.H., & Davis, R.M. (2024). "Performance Analysis of Hydro-Pneumatic Accumulators in Top Drive Systems." International Drilling Engineering Review, 52(1), 124-138.

3. Williams, J.B., Kumar, S., & Anderson, P.T. (2023). "Energy Storage Systems in Modern Drilling Operations: A Comprehensive Study." Offshore Technology and Engineering, 31(4), 203-217.

4. Mitchell, D.K., Zhang, L., & Roberts, C.A. (2024). "Reliability Assessment of Hydraulic Components in Marine Drilling Applications." Marine Engineering and Technology Quarterly, 29(2), 45-59.

Learn about our latest products and discounts through SMS or email