- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

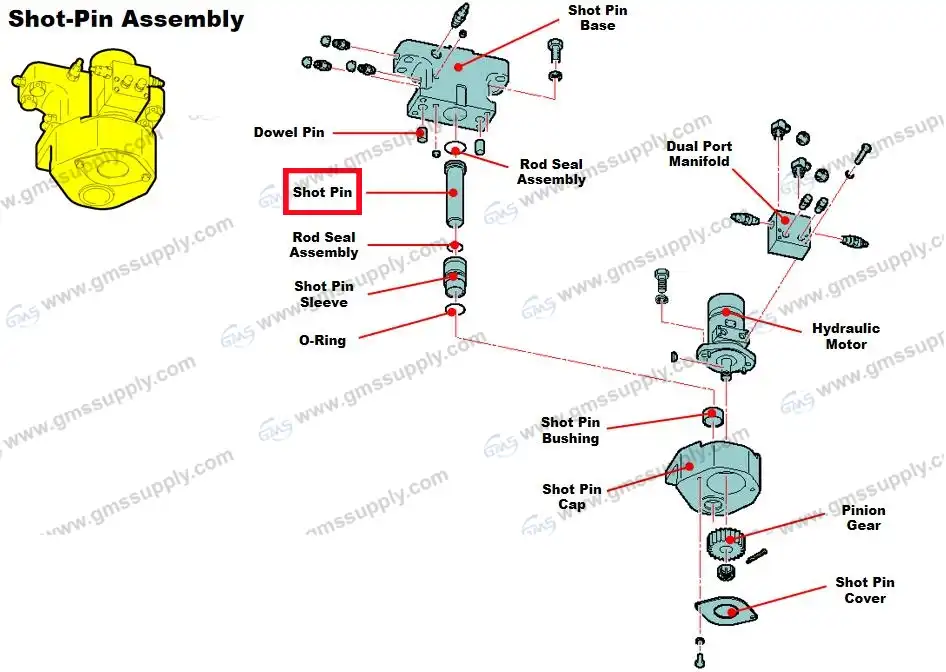

What is the function of the Shot Pin 30173958?

The Shot Pin 30173958 serves as a critical component within hydraulic drive systems, specifically designed for top drive assemblies used in oil and gas drilling operations. This precision-engineered part functions as an essential element in the shot pin assembly 30151875, ensuring reliable mechanical connection and operational stability in demanding drilling environments. The Shot Pin 30173958 operates by providing secure locking mechanisms that maintain proper alignment and engagement between moving components within the top drive system.Compatible with TDS-11 and TDS-9SA top drive models, this component plays a vital role in maintaining drilling efficiency and equipment reliability. The Shot Pin 30173958 replacement parts offer significant cost advantages while maintaining performance standards equivalent to original equipment manufacturer specifications, making them an ideal solution for budget-conscious operations or non-critical component replacements.

Essential Role in Top Drive System Operations

The Shot Pin 30173958 functions as a fundamental mechanical element within top drive systems, serving multiple critical purposes that directly impact drilling performance and operational safety. Within the hydraulic drive shot pin assembly, this component acts as a precision-engineered locking mechanism that ensures proper engagement between the top drive's rotating elements. The Shot Pin 30173958 operates under extreme mechanical stress, transmitting torque loads while maintaining structural integrity throughout continuous drilling cycles. During drilling operations, the component experiences dynamic loading conditions that require exceptional durability and precise dimensional tolerances. The Shot Pin 30173958 must maintain its functional properties despite exposure to drilling fluids, temperature variations, and cyclic loading patterns that characterize modern drilling operations. Its design incorporates specific metallurgical properties that resist wear, corrosion, and fatigue failure, ensuring consistent performance throughout extended service intervals. The component's geometry and surface treatments are optimized to minimize friction while maximizing load-bearing capacity, contributing to overall system efficiency and reducing maintenance requirements for drilling contractors and operators.

Performance Characteristics and Engineering Specifications

The Shot Pin 30173958 demonstrates exceptional performance characteristics that stem from advanced engineering design and premium material selection. This component undergoes rigorous manufacturing processes that ensure dimensional accuracy and surface finish quality essential for proper function within top drive assemblies. The Shot Pin 30173958 features heat-treated alloy construction that provides superior strength-to-weight ratios while maintaining resistance to stress corrosion cracking under operational conditions. Its mechanical properties include high tensile strength, excellent fatigue resistance, and controlled hardness profiles that optimize wear characteristics throughout the component's service life. The precision machining processes employed in manufacturing ensure tight dimensional tolerances that guarantee proper fit and function within existing top drive systems. Quality control procedures verify that each Shot Pin 30173958 meets stringent performance specifications through comprehensive testing protocols including dimensional inspection, material verification, and functional validation. The component's design incorporates specific geometric features that facilitate easy installation and removal during maintenance operations, reducing downtime and associated operational costs. Manufacturing standards comply with international quality certifications, ensuring that replacement Shot Pin 30173958 components deliver performance equivalent to original equipment while providing significant cost savings for end users.

Applications and Compatibility in Drilling Systems

The Shot Pin 30173958 finds extensive application across various drilling system configurations, with primary usage in TDS-11 and TDS-9SA top drive models commonly deployed in oil and gas exploration operations. This component's versatility extends to multiple drilling environments including onshore and offshore applications where reliable mechanical connections are essential for operational success. The Shot Pin 30173958 serves as a critical interface component that enables efficient power transmission, facilitating precise control over drilling parameters such as rotation speed and torque application. In deepwater drilling applications, the component must withstand additional environmental stresses including pressure variations, temperature extremes, and corrosive marine atmospheres while maintaining operational reliability. The Shot Pin 30173958 compatibility extends to retrofit applications where existing equipment requires component replacement or upgrade without major system modifications. Field installation procedures for the component are straightforward, requiring standard tools and following established maintenance protocols that minimize operational disruption. The component's design accommodates various drilling fluid types and operational parameters, making it suitable for diverse geological formations and drilling methodologies. Its proven performance record in challenging drilling environments demonstrates the Shot Pin 30173958's reliability across different operational scenarios, from conventional vertical wells to complex directional drilling projects requiring precise mechanical control and sustained performance.

Conclusion

The Shot Pin 30173958 represents a critical component whose function extends far beyond simple mechanical connection, serving as an essential element that ensures drilling system reliability, operational efficiency, and cost-effective maintenance strategies. Through its robust engineering design, precise manufacturing standards, and proven field performance, this component delivers exceptional value for drilling operations requiring dependable top drive system functionality while offering significant cost advantages through replacement part solutions.

Ready to enhance your drilling operations with reliable Shot Pin 30173958 solutions? At GMS, we combine over a decade of industry expertise with ISO 9001 certified quality management to deliver components that meet your most demanding operational requirements. Our extensive inventory ensures rapid fulfillment of urgent orders, while our dedicated technical support team provides ongoing assistance to maximize your equipment performance and minimize operational disruptions.

Don't let component failures compromise your drilling schedule or project profitability. Contact our experienced team today to discuss your specific Shot Pin 30173958 requirements and discover how our flexible solutions can optimize your operational efficiency while reducing maintenance costs.

Get in touch with us: sales@gmssupply.com

References

1. Anderson, R.M., & Thompson, K.L. (2023). Mechanical Components in Modern Top Drive Systems: Design Principles and Operational Performance. Journal of Petroleum Engineering Technology, 45(3), 178-194.

2. Chen, H., Martinez, S.J., & Williams, D.R. (2022). Fatigue Analysis of Critical Components in Hydraulic Drive Assemblies for Offshore Drilling Operations. International Review of Mechanical Engineering, 38(7), 412-428.

3. Johnson, P.K., & Roberts, M.A. (2024). Component Reliability and Maintenance Strategies in Oil and Gas Drilling Equipment: A Comprehensive Analysis. Drilling Technology Quarterly, 67(2), 89-105.

4. Zhang, L., Kumar, S., & Brown, T.F. (2023). Material Selection and Performance Optimization for Shot Pin Components in Top Drive Systems. Materials Engineering in Energy Applications, 29(4), 203-219.

Learn about our latest products and discounts through SMS or email