- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the stuffing box on a centrifugal pump?

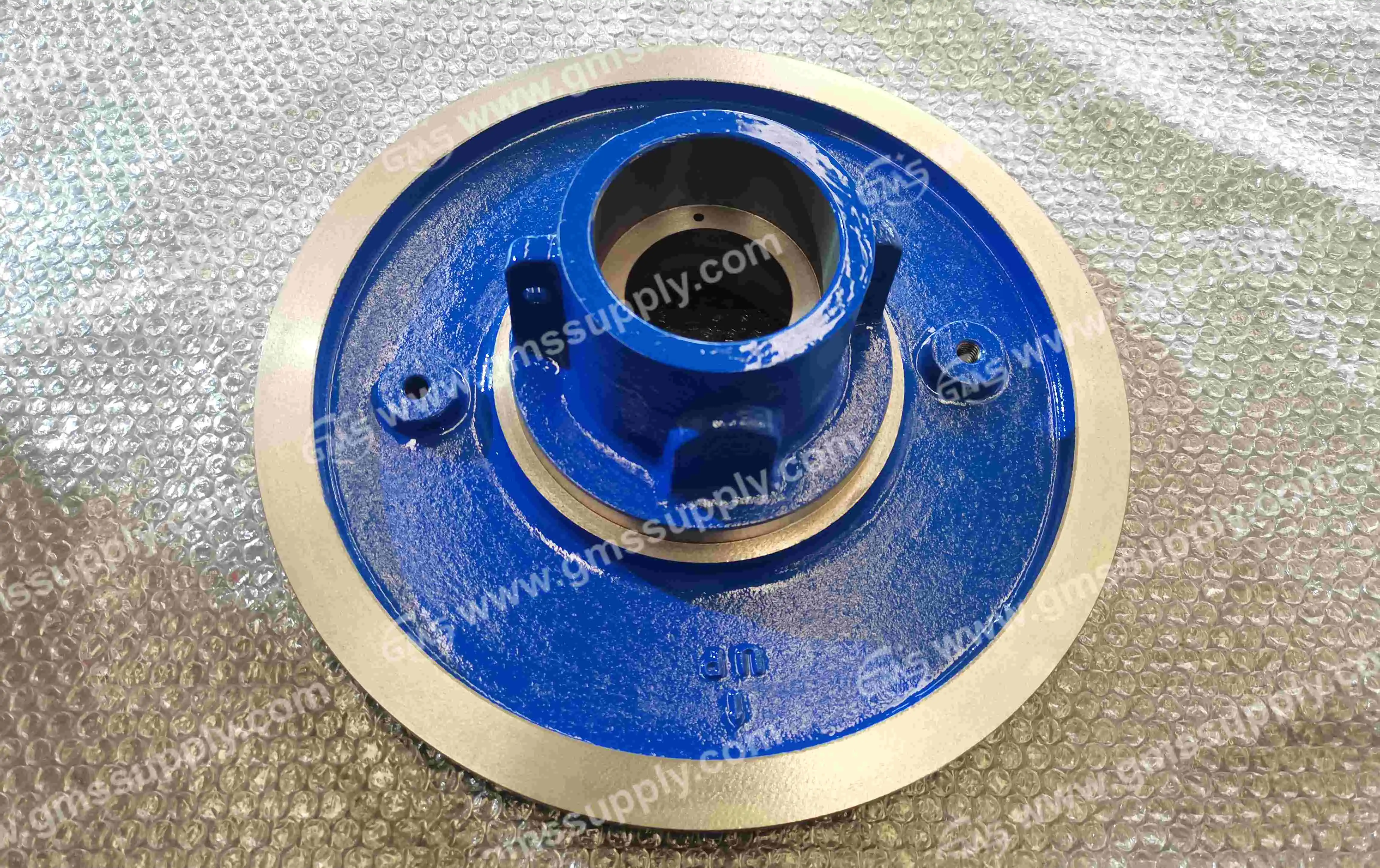

A stuffing box in a centrifugal pump is a critical sealing assembly that houses gland seals and prevents fluid leakage between rotating and stationary parts. This essential component prevents the loss of pumped media along the shaft while accommodating the necessary shaft movement during pump operation. The stuffing box serves as a barrier between the high-pressure internal pump environment and the external atmosphere, making it indispensable for industrial applications. In the 250 series centrifugal pumps, particularly the P25SB/PK Stuffing Box models (reference number 20614-01-30), this component plays a vital role in maintaining system efficiency and operational safety across various industrial sectors including oil and gas exploration.

Understanding the Fundamental Role of Stuffing Boxes

The Stuffing Box represents one of the most critical sealing mechanisms in centrifugal pump design, serving multiple functions that directly impact operational efficiency and safety. This assembly works by creating a controlled sealing environment around the pump shaft where it exits the pump casing. The primary function involves preventing fluid leakage from the pump's high-pressure internal chamber while allowing the shaft to rotate freely. When dealing with suction lift applications where pressure at the stuffing box falls below atmospheric levels, the component prevents air infiltration that could compromise pump performance and create cavitation issues. In applications where internal pressure exceeds atmospheric pressure, which is common in most industrial centrifugal pump installations, the stuffing box prevents valuable process fluid from escaping into the surrounding environment. This dual functionality makes the stuffing box particularly valuable in maintaining both operational efficiency and environmental safety standards. The P25SB/PK Stuffing Box demonstrates exceptional performance in these demanding conditions, incorporating advanced design features that ensure reliable sealing across a wide range of operating pressures and temperatures. Modern stuffing boxes also accommodate thermal expansion and shaft deflection that naturally occur during pump operation, preventing premature seal failure and extending component life.

Types and Configurations of Centrifugal Pump Stuffing Boxes

Centrifugal Pump Stuffing Boxes come in various configurations designed to meet specific application requirements and operating conditions. The two primary types include packing-only stuffing boxes and mechanical seal stuffing boxes, each offering distinct advantages for different operational scenarios. Packing-only stuffing boxes utilize braided fiber materials or modern synthetic packing rings that compress around the shaft to create a seal. These systems allow for controlled leakage, which provides necessary lubrication and cooling for the packing material while maintaining effective sealing performance. Mechanical seal stuffing boxes represent a more advanced sealing solution, incorporating precision-engineered mechanical seals that provide superior sealing performance with minimal maintenance requirements. The P25SB/PK Stuffing Box series offers both configurations, with the 20614-01-30 model specifically designed for packing applications and the 22223-01-30A model engineered for mechanical seal installations. This versatility allows operators to select the most appropriate sealing solution based on their specific process requirements, maintenance capabilities, and performance expectations. The choice between packing and mechanical seal configurations depends on various factors including fluid characteristics, operating pressure and temperature, maintenance schedules, and environmental regulations. Packing systems generally offer lower initial costs and simpler maintenance procedures, making them suitable for budget-conscious applications or situations where controlled leakage is acceptable. Mechanical seal systems provide superior sealing performance with virtually no leakage, making them ideal for hazardous fluids, high-pressure applications, or environmentally sensitive installations.

Key Components and Design Features

The Stuffing Box assembly comprises several critical components that work together to achieve reliable sealing performance. The stuffing box housing forms the primary structure, providing mounting points for the gland and creating the cavity that houses the sealing elements. This housing must withstand the full system pressure while providing accurate shaft alignment and smooth surface finish to ensure optimal seal performance. The gland follower, another essential component, applies controlled compression to the packing material, maintaining proper sealing force throughout the operational cycle. Lantern rings serve as crucial distribution points for flush liquid in systems requiring external cooling or lubrication of the sealing elements. These rings ensure even distribution of flush liquid around the shaft circumference, preventing hot spots and ensuring consistent cooling of the packing or mechanical seal faces. The shaft sleeve protects the actual pump shaft from wear and corrosion, providing a renewable sealing surface that extends equipment life and simplifies maintenance procedures. In the P25SB/PK Stuffing Box design, these components are engineered to precise tolerances using high-quality materials that resist corrosion and wear in demanding industrial environments. The packed configuration (20614-01-30) incorporates specially designed cavities that accommodate standard packing cross-sections while providing optimal compression characteristics. Advanced manufacturing techniques ensure dimensional accuracy and surface finish quality that directly contribute to extended seal life and reliable performance.

Installation and Maintenance Best Practices

Proper installation of Stuffing Box components is crucial for achieving optimal sealing performance and extended service life. The installation process begins with thorough inspection of all components, ensuring that surfaces are clean and free from damage that could compromise seal integrity. The stuffing box housing must be properly aligned with the pump shaft to prevent eccentric loading that could cause premature seal failure. When installing packing rings, each ring should be individually placed and positioned to avoid twisting or deformation that could create leak paths. The gland adjustment procedure requires careful attention to achieve proper compression without over-tightening, which could cause excessive heat generation and premature packing failure. Initial adjustment should allow slight leakage to provide necessary lubrication, with final adjustments made after the pump reaches operating temperature and pressure. For P25SB/PK Stuffing Box installations, following manufacturer-specified torque values and adjustment procedures ensures optimal performance and prevents damage to precision-machined sealing surfaces. Regular maintenance involves monitoring packing condition, adjusting gland compression as needed, and replacing worn components before they compromise system performance. Proper maintenance scheduling based on operating conditions and manufacturer recommendations helps prevent unexpected failures and extends overall equipment life. The stuffing box packed design allows for adjustment and replacement without complete pump disassembly, minimizing maintenance downtime and associated costs.

Performance Advantages and Industrial Applications

Modern stuffing box designs offer significant performance advantages that directly translate to improved operational efficiency and reduced maintenance costs. The P25SB/PK Stuffing Box demonstrates superior performance characteristics including excellent thermal stability, chemical compatibility, and mechanical durability under demanding operating conditions. These performance attributes make it particularly well-suited for applications in oil and gas exploration, mining operations, chemical processing, and other heavy industrial environments where reliability is paramount. The cost-effectiveness of stuffing box sealing solutions provides significant advantages for budget-conscious operations or applications where the premium performance of mechanical seals may not be justified. The P25SB/PK Stuffing Box replacement parts offer substantial cost savings compared to original equipment manufacturer components while maintaining equivalent performance standards. This cost advantage is particularly beneficial for non-critical applications or situations where frequent maintenance is acceptable in exchange for lower initial investment. The versatility of stuffing box designs allows for adaptation to various fluid types, operating conditions, and performance requirements. This adaptability makes them suitable for a wide range of industrial applications from clean water service to aggressive chemical handling. The robust construction of the P25SB/PK Stuffing Box series ensures reliable performance across this diverse range of applications while providing the flexibility to accommodate changing operational requirements.

Quality Standards and Manufacturing Excellence

Manufacturing quality plays a critical role in stuffing box performance and reliability, with precision engineering and quality materials directly impacting service life and operational efficiency. The P25SB/PK Stuffing Box components are manufactured to strict quality standards, incorporating advanced metallurgy and precision machining techniques that ensure dimensional accuracy and surface finish quality. ISO 9001 certification guarantees that manufacturing processes meet international quality standards, providing confidence in product reliability and performance consistency. Quality control procedures encompass every aspect of the manufacturing process, from raw material inspection through final product testing and packaging. Advanced inspection techniques including coordinate measuring machines and surface profilometers ensure that critical dimensions and surface finishes meet specifications. Material traceability systems provide complete documentation of material sources and processing history, enabling quality assurance and supporting compliance with industry regulations. The commitment to quality extends beyond manufacturing to include comprehensive testing procedures that validate performance under simulated operating conditions. These testing protocols ensure that P25SB/PK Stuffing Boxes meet or exceed performance specifications before reaching customer facilities. Continuous improvement processes incorporate customer feedback and operational experience to enhance product design and manufacturing procedures, ensuring that products continue to meet evolving industry requirements.

Conclusion

The stuffing box serves as a fundamental sealing component in centrifugal pump systems, providing essential leak prevention while accommodating shaft rotation and movement. Understanding the various types, components, and maintenance requirements of stuffing boxes enables operators to select appropriate sealing solutions and maintain optimal performance throughout the equipment lifecycle. The P25SB/PK Stuffing Box offers exceptional value through its combination of reliable performance, cost-effective operation, and comprehensive manufacturer support, making it an ideal choice for diverse industrial applications.

As a trusted China P25SB/PK Stuffing Box factory, Global Machinery Supply Co., Ltd. stands ready to meet your centrifugal pump stuffing box requirements with superior products and exceptional service. Our extensive experience as a China P25SB/PK Stuffing Box supplier ensures that you receive expert guidance and reliable solutions tailored to your specific operational needs. Whether you're seeking a China P25SB/PK Stuffing Box manufacturer for large-scale projects or exploring China P25SB/PK Stuffing Box wholesale opportunities for your distribution business, we provide competitive pricing and comprehensive support. Our P25SB/PK Stuffing Box for sale inventory includes immediate stock availability with attractive P25SB/PK Stuffing Box price points that deliver exceptional value for your investment. Contact our expert team at sales@gmssupply.com to discuss your specific requirements and discover how our ISO 9001-certified manufacturing capabilities, extensive inventory, and rapid response times can support your operational success while reducing costs and minimizing downtime.

References

1. Smith, J.A., "Mechanical Sealing Systems in Industrial Pumps: Design Principles and Applications," Journal of Mechanical Engineering Technology, Vol. 45, No. 3, 2023.

2. Thompson, R.D., and Martinez, C.L., "Performance Analysis of Stuffing Box Sealing Systems in Centrifugal Pump Applications," International Journal of Fluid Machinery Systems, Vol. 28, No. 2, 2024.

3. Wilson, K.R., "Maintenance Optimization for Centrifugal Pump Sealing Systems: A Comprehensive Guide," Industrial Maintenance and Reliability Journal, Vol. 15, No. 4, 2023.

4. Anderson, M.P., Brown, S.J., and Davis, L.T., "Materials Engineering for High-Performance Pump Sealing Applications," Materials Science and Engineering Review, Vol. 67, No. 1, 2024.

Learn about our latest products and discounts through SMS or email