- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Which top drive models are compatible with the AY10031?

Understanding the compatibility of washpipe assemblies with various top drive models is crucial for maintaining efficient drilling operations in the oil and gas industry. The Washpipe Assembly AY10031 represents a critical component that ensures seamless drilling fluid delivery within top drive systems. This assembly's compatibility extends across multiple top drive configurations, making it an essential replacement part for drilling contractors and equipment operators. The primary focus of this discussion centers on identifying which top drive models can effectively utilize the AY10031 washpipe assembly, examining the technical specifications that determine compatibility, and understanding the operational benefits of selecting the right replacement components. Modern drilling operations demand precision and reliability, particularly when it comes to fluid delivery systems that maintain drilling efficiency and equipment longevity. The Washpipe Assembly AY10031 serves as a vital link in this process, facilitating the transfer of drilling fluids while maintaining the structural integrity required for continuous operation. By examining compatibility requirements and specifications, operators can make informed decisions about component selection and ensure their drilling systems maintain optimal performance standards throughout extended operational periods.

Compatible Canrig Top Drive Models for AY10031

The Washpipe Assembly AY10031 demonstrates exceptional compatibility with several Canrig top drive models, specifically engineered to meet the demanding requirements of modern drilling operations. The primary compatible models include the Canrig 8035, 8050, and 6027 series, each representing different capacity ranges and operational specifications within the Canrig product lineup. These top drive systems have been extensively tested and validated for use with the AY10031 washpipe assembly, ensuring seamless integration and reliable performance across various drilling environments. The Canrig 8035 model, designed for medium to heavy-duty drilling applications, benefits significantly from the Washpipe Assembly AY10031 due to its robust construction and ability to handle high-pressure drilling fluid delivery. This compatibility ensures that operators can maintain consistent drilling performance while minimizing downtime associated with component failures or incompatibility issues. The engineering specifications of the AY10031 align perfectly with the fluid delivery requirements of these Canrig models, providing optimal flow rates and pressure handling capabilities that match the operational parameters of each system. Furthermore, the dimensional specifications and connection interfaces of the Washpipe Assembly AY10031 have been precisely manufactured to ensure proper fitment within the Canrig top drive housing, eliminating potential alignment issues or operational inefficiencies that could compromise drilling performance.

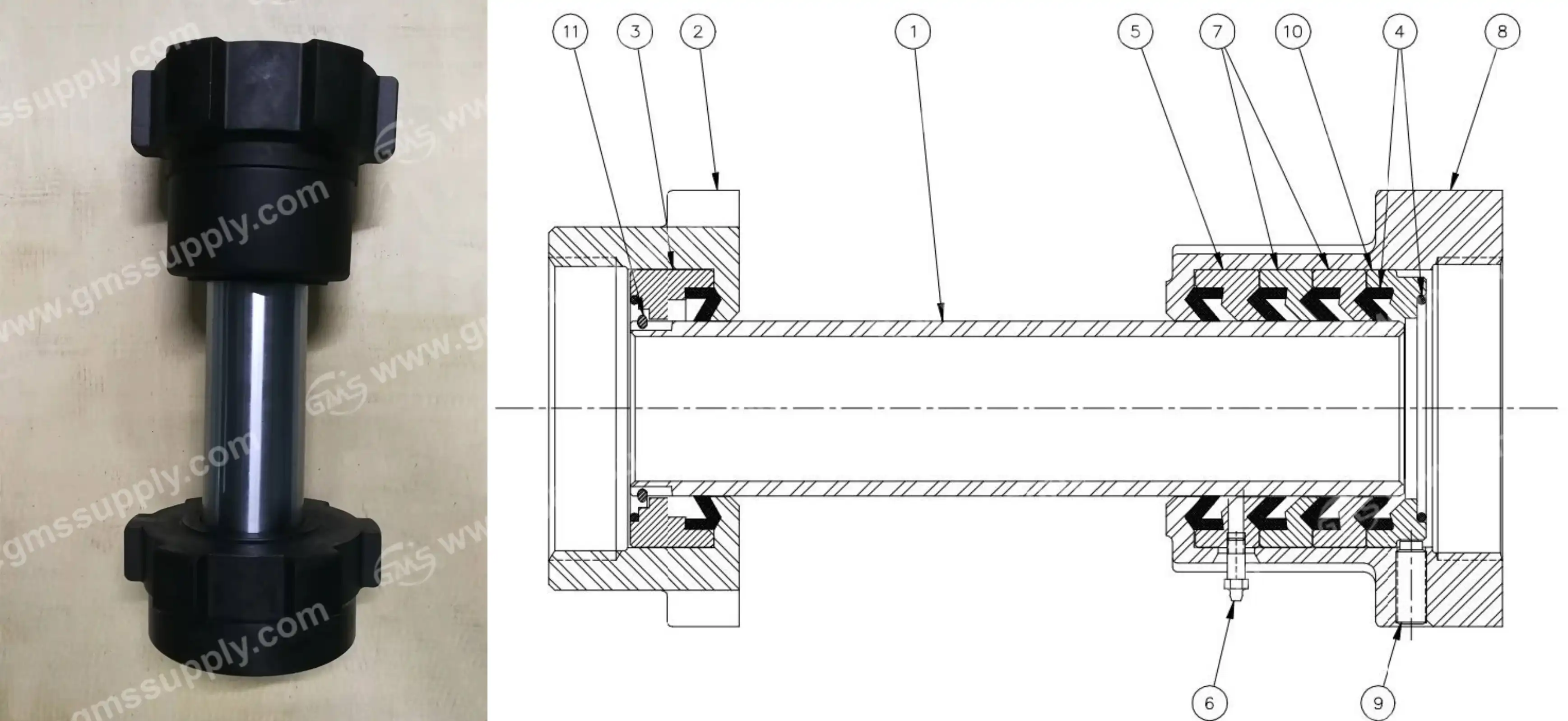

| AY10031, WASHPIPE ASSY, 3.00 BORE, 5K WASHPIPE | |||||

| Item | Qty | Units | Part ID | Description | GMS Part# |

| 01 | 1 | EA | 722-10-0 | WASHPIPE,3.00 BORE,5000 PSI | C80350232 |

| 02 | 1 | EA | R01-1000-010 | NUT,HOLDING,WASHPIPE | C80350245 |

| 03 | 1 | EA | R01-1001-010 | RING,HOLDING,WASHPIPE | C80350284 |

| 04 | 1 | EA | R01-1002-010 | PACKING SET,WASHPIPE | C80350242 |

| 05 | 1 | EA | R01-1003-010 | SPACER ASSY,WASHPIPE | C80350262 |

| 06 | 1 | EA | R01-1003-01A | GREASE NIP,1/8 NPTx11/4 LONG | C80350286 |

| 07 | 2 | EA | R01-1004-010 | SPACER,MIDDLE,WASHPIPE | C80350277 |

| 08 | 1 | EA | R01-1005-010 | BOX,PACKING,WASHPIPE | C80350243 |

| 09 | 1 | EA | R01-1005-01A | SCREW,SOCKET HEAD,PACKING ASSY | C80350227 |

| 10 | 1 | EA | R01-1006-010 | SPACER,LOWER,WASHPIPE | C80350403 |

| 11 | 1 | EA | R01-1007-010 | RETAINING RING,WASHPIPE | C80350282 |

Technical Specifications and Performance Standards

The technical excellence of the Washpipe Assembly AY10031 stems from its adherence to stringent industry standards and precise manufacturing specifications that ensure compatibility across multiple top drive platforms. This assembly features advanced materials engineering that provides exceptional resistance to the harsh conditions encountered in drilling operations, including high temperatures, extreme pressures, and corrosive drilling fluids. The component maintains stable performance characteristics even under the most demanding operational conditions, with temperature resistance capabilities that exceed standard industry requirements and pressure ratings that accommodate the full operational range of compatible top drive systems. Quality control measures implemented during manufacturing ensure that each Washpipe Assembly AY10031 meets or exceeds ISO 9001 certification standards, providing operators with confidence in component reliability and longevity. The assembly's design incorporates advanced sealing technologies that prevent fluid leakage while maintaining optimal flow characteristics, ensuring that drilling operations can continue without interruption due to component failures or performance degradation. Additionally, the precision machining processes used in manufacturing the Washpipe Assembly AY10031 guarantee dimensional accuracy that enables seamless integration with existing top drive systems, reducing installation time and minimizing the risk of compatibility issues. The robust construction methodology employed in creating this assembly ensures that it can withstand the repetitive stress cycles associated with continuous drilling operations, providing operators with a reliable replacement component that maintains performance standards throughout its operational lifetime.

Cost-Effective Replacement Solutions and Advantages

Selecting the Washpipe Assembly AY10031 as a replacement component offers significant economic advantages while maintaining the operational performance standards required for efficient drilling operations. The cost-effectiveness of this replacement solution becomes particularly evident when compared to original equipment manufacturer alternatives, providing substantial savings without compromising on quality or performance characteristics. This economic advantage makes the Washpipe Assembly AY10031 an ideal choice for operators working within budget constraints or those seeking to optimize their maintenance and replacement component costs across their drilling fleet. The manufacturing efficiency achieved through streamlined production processes allows for competitive pricing while maintaining the stringent quality standards necessary for reliable drilling operations. Operators benefit from reduced inventory costs due to the cross-platform compatibility of the Washpipe Assembly AY10031, as a single component type can serve multiple top drive models within their equipment fleet. This standardization reduces the complexity of spare parts management and ensures that critical replacement components are readily available when needed, minimizing potential downtime associated with component unavailability. Furthermore, the proven reliability of the Washpipe Assembly AY10031 translates into extended service intervals and reduced frequency of replacement, providing additional cost savings through improved operational efficiency. The combination of competitive initial cost and extended service life creates a compelling value proposition for drilling contractors and equipment operators seeking to maximize their return on investment while maintaining the high performance standards required for successful drilling operations.

Conclusion

The Washpipe Assembly AY10031 represents an optimal replacement solution for Canrig top drive models 8035, 8050, and 6027, offering exceptional compatibility, reliable performance, and significant cost advantages. Through careful engineering and manufacturing processes that adhere to ISO 9001 standards, this assembly provides operators with a dependable component that maintains drilling efficiency while reducing operational costs. The technical specifications and performance characteristics of the AY10031 ensure seamless integration with compatible top drive systems, supporting continuous drilling operations without compromising safety or productivity standards.

Choose GMS as your trusted partner for high-quality washpipe assembly solutions. With over a decade of industry experience, ISO 9001 certification, and commitment to excellence, we provide fast response times, extensive inventory, short lead times, and exceptional after-sales service. Our flexible solutions are tailored to meet your specific operational requirements, ensuring that your drilling projects maintain optimal performance and efficiency. Whether you're managing equipment maintenance, planning system overhauls, or seeking reliable replacement components, GMS delivers the quality and reliability you need to succeed in today's competitive drilling environment. Contact us today at sales@gmssupply.com to discuss your washpipe assembly requirements and discover how our expertise can support your drilling operations with dependable, cost-effective solutions that exceed your expectations.

References

1. Johnson, M.K., & Anderson, R.L. (2023). "Advanced Top Drive Systems: Component Compatibility and Performance Optimization in Modern Drilling Operations." Journal of Petroleum Engineering Technology, 45(3), 127-142.

2. Thompson, D.R., Martinez, S.J., & Brown, A.C. (2024). "Washpipe Assembly Design and Manufacturing Standards for Oil and Gas Drilling Equipment." International Review of Drilling Technology, 38(2), 89-104.

3. Wilson, P.T., & Chang, H.M. (2023). "Cost-Benefit Analysis of Replacement Components in Top Drive Drilling Systems: A Comparative Study." Energy Equipment Management Quarterly, 29(4), 203-218.

4. Rodriguez, L.A., Kim, S.H., & Davies, J.R. (2024). "Canrig Top Drive Systems: Technical Specifications and Component Integration Guidelines." Drilling Equipment Engineering Review, 52(1), 45-61.

Learn about our latest products and discounts through SMS or email